Website:

LITOKOL

Website:

LITOKOL

Excertos do catálogo

Litokol X12 IMPROVED CEMENTITIOUS ADHESIVE WITH NO VERTICAL SLIP AND EXTENDED OPEN TIME FOR THE INSTALLATION OF CERAMIC AND PORCELAIN TILES AND NATURAL STONES ON INTERIOR AND EXTERIOR WALLS AND FLOORS. SUITABLE FOR OVERLAYING AND UNDERFLOOR HEATING. PRODUCT WITH VERY LOW VOLATILE ORGANIC COMPOUND EMISSION RATE. ADVANTAGES / FEATURES • Product with very low volatile organic compound (VOC) emission rate. Complies with class EC1PLUS according to the EMICODE protocol and class A+ (Émission dans l’air intérieur - French Regulations) • Maintains excellent workability over time, without any bothersome thickening • Allows the installation of ceramic, porcelain and mosaic wall coverings without the need for plastic spacers • Suitable for installation on heating screeds • Suitable for overlaying on existing flooring 20 kg bags - 1,200 kg standard pallet Intended uses Interiors - exteriors Floors and walls Underfloor heating Façades Overlaying Terraces and balconies Residential, public, commercial building INSTALLATION PLANNING The only way to guarantee the long-lasting performance of ceramic and porcelain tile installations is to properly plan the process. It is therefore advisable to consult the national regulations in force in each country, for example standard UNI 11493 in Italy, which provides all necessary instructions regarding the choice of materials, correct planning, use and installation, so as to ensure all quality, performance and durability standards are safely met. Suitable materials Ceramic and porcelain tiles Double fired Single fired Terracotta - Clinker Marble – Granite – Stone Natural stones Ceramic and vitreous mosaics Porcelain stoneware Suitable substrates Cement screeds Self-levellers Skim coats Existing tiles Waterproofing systems Underfloor heating systems Concrete Gypsum Fibre cement slabs Gypsum and anhydrite Aerated concrete Plasters Some of the general precautions that need to be followed are listed below as an example. Substrates Before installation, check that substrates are clean, free of loose fragments, properly dried and cured, flat and level, and that mechanical strength requirements based on the intended use have been met. Worksite conditions Check the suitability of the temperature, humidity, light conditions etc. at the time of the product’s application. Materials Check that all materials used for tiling (ceramic materials, levelling systems, adhesives, grouts, waterproofing products, etc.) are suitable for the intended use and have been correctly stored. Expansion joints Check that the perimeter, expansion, divider and structural elastic joints have been correctly designed and prepared. Divider joints are normally needed for 20/25 m2 indoor sections, and 9-15m2 outdoor sections. For exteriors, make sure joints are properly waterproofed and sealed. Back-buttering For exterior installations, large tiles, floors with intense or heavy traffic, vibrating supports and situations exposed to Cementitious adhesiv

Abrir o catálogo na página 1

high temperature fluctuations, the adhesive mortar must be applied to both the substrate and the back of the tiles so as to obtain a solid bed of adhesive without any air bubbles. Joints In any type of ceramic and porcelain tiling, suitably sized joints must be created based on the following parameters: • Type, format and size tolerance of tiles • thermal expansion coefficients of tiling materials • mechanical properties of installation materials • position and trajectory of joints • mechanical features of substrate • Intended use and operating conditions Butt joints are not allowed. Any...

Abrir o catálogo na página 2

(5) After treatment with Primer C or Primer X94 for non-waterproof gypsum. (6) After treatment with Primer X94. The substrates must be clean, solid, compact, crack-free, properly cured and without rising damp. If it becomes necessary to create a slope, for example on balconies or footpaths, a levelling layer can be created using suitable levelling products such as Litoplan Smart. • Excessively porous and absorbent or powdery substrates must be treated with the consolidating primer Primer C • Smooth and compact substrates such as smoothed concrete, existing ceramic or agglomerate coverings,...

Abrir o catálogo na página 3

be used with a variable supply water temperature between +20°C and +25°C, kept constant for at least 3 days. Then set the maximum design temperature and hold it for another 4 days. At the end of this cycle, bring the screed back to ambient temperature and install the covering (see standard EN 1264-4). Joints can be grouted after approximately 6-8 hours in the case of wall tiles and after 24 hours in the case of floor tiles. For grouting, it is possible to use the cementitious grouts Stylegrout 0-8, Stylegrout 3-20, Stylegrout Tech or the ready-to-use polymer mortar FillGood EVO, or, for...

Abrir o catálogo na página 4

Powered by TCPDF (www.tcpdf.org) Compliance Initial tensile adhesion strength after 28 days Tensile adhesion strength after water immersion Tensile adhesion strength after heat action Tensile adhesion strength after freeze/thaw cycles Open time Slip Resistance to alkalis Resistance to solvents Resistance to acids Data detection at temperature +23 °C, R.H. 50% and with no wind. May vary depending on the specific conditions of the installation site. Data Sheet n. 001/B Revision n. 7 Date: January 2021 The information and provisions contained in this technical data sheet reflect our best...

Abrir o catálogo na página 5Todos os catálogos e folhetos técnicos da LITOKOL

-

Aquamaster EVO

24 Páginas

-

Ottoseal S105

4 Páginas

-

Consolidante Universale EVO

4 Páginas

-

Faster EVO

2 Páginas

-

Litotex

3 Páginas

-

Multifondo EVO

6 Páginas

-

Litoside

2 Páginas

-

Litogap

2 Páginas

-

Litostick X35

2 Páginas

-

Hydrolux EVO

5 Páginas

-

Prepara Fondo EVO

3 Páginas

-

Primer C

2 Páginas

-

Primer X94

3 Páginas

-

Concrete Primer

2 Páginas

-

Idrostuk

4 Páginas

-

Latexkol

4 Páginas

-

Idrokol X20

3 Páginas

-

Litosil MS

2 Páginas

-

Litoswell

3 Páginas

-

Litostop Water

2 Páginas

-

Litoband Koll

3 Páginas

-

Litomesh

2 Páginas

-

Litoband S.A.T.

3 Páginas

-

Litoproof Extreme

7 Páginas

-

Litoband Basic

3 Páginas

-

LITOBAND SK PIPES COLLAR

3 Páginas

-

LITOBAND SK IC & EC

3 Páginas

-

Litoband

2 Páginas

-

Litoproof Plus

8 Páginas

-

Litoband SK Net

3 Páginas

-

Litoband SK Tape

3 Páginas

-

Primer SK

3 Páginas

-

Primer F

3 Páginas

-

Hidroflex

6 Páginas

-

Osmogrout

4 Páginas

-

Elastocem

6 Páginas

-

Coverflex

6 Páginas

-

Litoscrub EVO

2 Páginas

-

Litoshine EVO

2 Páginas

-

Litostain Cleaner

2 Páginas

-

Litogrip Floor

2 Páginas

-

Litowax

2 Páginas

-

Litocare Stone Glossy

2 Páginas

-

Litostone Protector

2 Páginas

-

Litogres Protector

2 Páginas

-

Litocare Matt

3 Páginas

-

Litoseal Terrazze

2 Páginas

-

Litostrip

2 Páginas

-

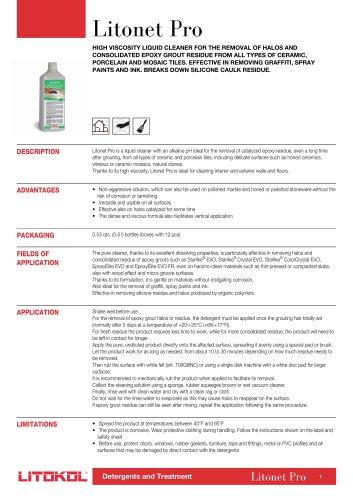

Litonet Pro

2 Páginas

-

FillCleaner EVO

2 Páginas

-

Litonet Gel EVO

2 Páginas

-

Litonet EVO

2 Páginas

-

Litoclean EVO

2 Páginas

-

Litoclean

2 Páginas

-

X-GLM SMOOTHING

2 Páginas

-

X-GL SMOOTHING

2 Páginas

-

OTTO Cleaner T

2 Páginas

-

OTTO Primer 1217

2 Páginas

-

OTTO Cleanprimer 1101

2 Páginas

-

OTTO Primer 1218

2 Páginas

-

OTTO Primer 1105

2 Páginas

-

OTTO Primer 1216

2 Páginas

-

Ottocoll M501

3 Páginas

-

Ottocoll M500

4 Páginas

-

Ottoseal S125

4 Páginas

-

Ottoseal S117

4 Páginas

-

Ottoseal S34

4 Páginas

-

Ottoseal S70

4 Páginas

-

Ottoseal S100

4 Páginas

-

STARLIKE EVO FINISHES

5 Páginas

-

Defender EVO

3 Páginas

-

StyleGrout 3-20

5 Páginas

-

StyleGrout 0-8

5 Páginas

-

StyleGrout Tech

5 Páginas

-

Grouts FillGood EVO

7 Páginas

-

EpoxyElite EVO FR

7 Páginas

-

Grouts EpoxyElite EVO

8 Páginas

-

StenDecor

3 Páginas

-

Starlike Decor

5 Páginas

-

Starlike ColorCrystal EVO

7 Páginas

-

Starlike Crystal EVO

7 Páginas

-

Grouts STARLIKE EVO

10 Páginas

-

Litoelastic EVO FR

6 Páginas

-

Litoelastic EVO

6 Páginas

-

Litoacril Plus

4 Páginas

-

Litoacril LA315

4 Páginas

-

Litoacril LA201

4 Páginas

-

Litoacril Fix

4 Páginas

-

Rapidflex K91

5 Páginas

-

Litorapid K90

5 Páginas

-

Hyperflex K100

6 Páginas

-

Superflex K77

6 Páginas

-

Powerflex K50

5 Páginas

-

Litoplus K55

6 Páginas

-

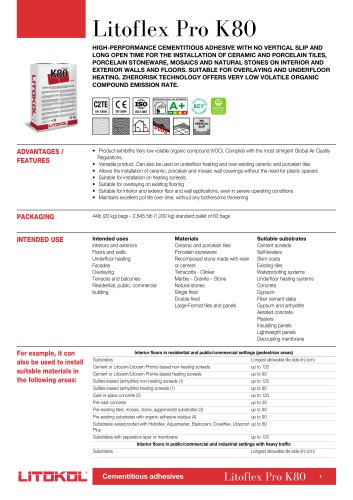

Litoflex Pro K80

7 Páginas

-

X11

5 Páginas

-

K18

4 Páginas

-

K17

5 Páginas

-

Litoplan Smart

3 Páginas

-

Litoliv Express

3 Páginas

-

Litoliv Extra 15

3 Páginas

-

Litoliv S40 Eco

3 Páginas

-

Litocem Pronto

4 Páginas

-

Litocem

4 Páginas

-

ETR

1 Páginas

-

EAT

1 Páginas

-

ETA

1 Páginas

-

ERA

1 Páginas

-

TDP - TDF

1 Páginas

-

ESA - EFA

1 Páginas

-

GC28

1 Páginas

-

MCA, MCB, MCS

2 Páginas

-

MLB

1 Páginas

-

RSS

1 Páginas

-

RAD

1 Páginas

-

RAA

1 Páginas

-

RUA - RSA

1 Páginas

-

TGA

1 Páginas

-

TCS

1 Páginas

-

TSC

1 Páginas

-

TAV

1 Páginas

-

TAS

1 Páginas

-

SpazioMateria EVO

4 Páginas

-

SpazioChiaroscuro EVO

4 Páginas

-

SpazioLamina EVO Perlato

5 Páginas

-

SpazioLamina EVO Crudo

5 Páginas

-

SpazioLamina EVO Ossidato Ramato

5 Páginas

-

SpazioLamina EVO CORTEN

5 Páginas

-

SpazioCemento EVO

5 Páginas

-

SpazioResina EVO

5 Páginas

-

LITOTEX EXTREME

9 Páginas

-

LITOSIL

11 Páginas

-

LitoJoint EVO

7 Páginas

-

EpoxyÉlite EVO

9 Páginas

-

SPAZIOCONTINUO LE RESINE DI LITOKOL

100 Páginas

-

BattiSpazio

3 Páginas

-

ResinaArredo EVO

5 Páginas

-

DS_SpazioMateria EVO_grb

4 Páginas

-

DS_Defender EVO_grb

2 Páginas

-

FillGood EVO

17 Páginas

-

EpoxyElite EVO the first grout

21 Páginas

-

Starlike EVO

34 Páginas

-

Spaziocontinuo

100 Páginas

-

StyleGrout

25 Páginas

-

LITOLEVEL

2 Páginas

-

UserCatalogue

113 Páginas

-

Aquamaster Leaflet

12 Páginas