Excertos do catálogo

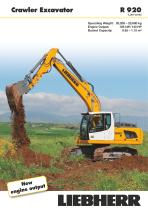

Crawler Excavator R 920 Operating Weight: 20,200 – 23,600 kg Engine Output: 105 kW / 143 HP Bucket Capacity: 0.55 – 1.15 m³

Abrir o catálogo na página 1

Operating Weight: 20,200 - 23,600 kg Engine Output: 105 kW / 143 HP

Abrir o catálogo na página 2

Liebherr’s R 920 combines power, precision and versatility. Its characteristics guarantee its excellent performance in a wide variety of applications, including the toughest. And its movements attain an unequalled level of smoothness and precision thanks to the latest generation hydraulic system. The R 920 is therefore suitable for both light and heavy daily tasks. The dozing blade, a key feature of this excavator, is added to a vast range of tools and undercarriages which make it essential. The operator’s well-being is a fundamental consideration for Liebherr when developing its products....

Abrir o catálogo na página 3

A Liebherr engine that is even cleaner and with enhanced performance • New engine complies with the Stage IIIB emission standards • Especially designed for construction machine applications • The most cutting-edge technology with the Liebherr Common-rail system • Automatic idling system optimises energy efficiency

Abrir o catálogo na página 4

Performance Liebherr’s R 920 combines power, precision and versatility. Its characteristics guarantee its excellent performance in a wide variety of applications, including the toughest. And its movements attain an unequalled level of smoothness and precision thanks to the latest generation hydraulic system. The R 920 is therefore suitable for both light and heavy daily tasks. The dozing blade, a key feature of this excavator, is added to a vast range of tools and undercarriages which make it essential. Liebherr integrated systems engineering Cutting-edge technology The R 920 excavator...

Abrir o catálogo na página 5

Likufix and Tool-Management • Ideal for worksites requiring tool changes • Mechanical and hydraulic coupling of tools possible without leaving the cab • Optimised excavator operation with automatic tool change system • Intelligent Tool-Management option, for automatic tool detection, pressure and corresponding flow adjustment

Abrir o catálogo na página 6

Economy The grouping together of the maintenance components and their accessibility from ground level reduces intervention times on the R 920. The centralised lubrication system, fitted as standard, and the use of solutions such as Likufix, increase the excavator’s productivity. Therefore the return on investment of the R 920 is guaranteed. Indisputable cost-effectiveness in the short, medium and long-term Shorter maintenance times All the maintenance points have been designed for easier access and to make the daily maintenance operations shorter. The gull-wing doors provide access to the...

Abrir o catálogo na página 7

7" colour touch screen • Several adjustment, control and monitoring possibilities (fuel consumption display, air-conditioning, tool control, radio, etc.) • Robust and reliable design (ingress protection rating IP 65) • High resolution video compatibility for displaying the backup camera images

Abrir o catálogo na página 8

Comfort The operator’s well-being is a fundamental consideration for Liebherr when developing its products. Liebherr’s excavators, including the R 920, all have a quiet, ergonomic and spacious operator’s cab that fully satisfies the operator’s needs. This outstanding comfort is very highly appreciated. And finally, the enhanced visibility of the machine’s direct work environment allows the operator greater peace of mind while performing their daily work. When work becomes pleasure A first class work space In this cab, the operator has a pneumatic seat, an enlarged space and a very...

Abrir o catálogo na página 9

Key Liebherr components • Perfect harmonisation of the machine’s elements for worksite applications • Main mechanically-welded structures (undercarriage, attachments, upper-carriage) developed by Liebherr • Liebherr manufacturing: - combustion engine - hydraulic pumps - transfer case - transmission - orientation mechanism - slew ring - electronic components

Abrir o catálogo na página 10

Reliability With 50 years of experience designing and manufacturing hydraulic crawler excavators, Liebherr France SAS is in a strong position to offer its customers ever more reliable machines. The high quality of the product is guaranteed at all the stages, from design to manufacture, while the safety and comfort of the operator’s working conditions have been enhanced even further. This recognized reliability is also to be found in the numerous services that Liebherr has specifically developed for assisting and satisfying its customers. Robustness at all levels Better force distribution...

Abrir o catálogo na página 11

Variety of robust attachments • Moulded steel joints for greater stress resistance • Parts have a long service life thanks to the automated lubrication, fitted as standard • Wide choice of attachments to adapt the excavator to the customer's needs A multi-purpose tool carrier • Wide range of specific Liebherr buckets and tools • Patented Liebherr tooth system for increased productivity • Likufix quick-change coupling system for greater flexibility Work in complete safety • Backup camera fitted in the for a clear view and increased operating • Protected access to the uppercarriage and cab •...

Abrir o catálogo na página 12

• Spacious and air-conditioned work space for increased productivity • Pneumatic seat as standard • 7" high resolution, easy-to-use, colour touch screen • Fully retractable window screen The latest technology for heightened performance • New Liebherr Stage IIIB engine technology with oxidation catalyst • Automatic idling and engine cut-off in the event of inactivity • Positive Control hydraulic system with Liebherr electronics for more accurate and fluid movements Reduced maintenance time Completely new maintenance concept with elements within arm's reach, accessible from the ground Filters...

Abrir o catálogo na página 13

Swing Drive Displacement __ Engine operation___ Exhaust gas treatment Option ______________ Fuel tank _________________ Electrical system Voltage _____________ Engine idling _______ Motor management ____ 105 kW (143 HP) at 1,800 RPM Liebherr D 834 Al 4 cylinder in-line 108/125 mm 4.58 l 4-stroke diesel Common-Rail injection system exhaust-gas recirculation (eagr) oxidation catalyst emission standard stage IIIB Liebherr particle filter water-cooled and integrated motor oil cooler, after-cooled and fuel cooled dry-type air cleaner with pre-cleaner, primary and safety elements 341 l 24 V 2 x...

Abrir o catálogo na página 14Todos os catálogos e folhetos técnicos da Liebherr

-

HS 8070.1

28 Páginas

-

LRB 23

20 Páginas

-

MK 73-3.1

28 Páginas

-

MK 88-4.1

20 Páginas

-

LRS 545

5 Páginas

-

LRS 545-31 Toplift

3 Páginas

-

LRS 565-31 Intermodal

3 Páginas

-

Litronic- FMS III/CCS

2 Páginas

-

T 236

24 Páginas

-

L 507 – L 518

34 Páginas

-

L 506 / L 508

20 Páginas

-

Deep Foudation Work

48 Páginas

-

TA 230

16 Páginas

-

Telescopic Handlers

22 Páginas

-

Your Mining Partner

28 Páginas

-

T 284

24 Páginas

-

Liebherr Components

8 Páginas

-

A 916

30 Páginas

-

R 918

28 Páginas

-

R 914 Compact

16 Páginas

-

A 910 Compact

26 Páginas

-

Rotary drilling tools

20 Páginas

-

Liebherr concrete technology

16 Páginas

-

Tower Cranes

42 Páginas

-

Horticultural and Landscape Construction

24 Páginas

-

stationary concrete pumps

20 Páginas

-

truck-mounted concrete pumps

20 Páginas