Excertos do catálogo

Grease separators for underground installation Oil-, Fuel- and Coalescence separators Sediment separators Starch separators Grease separators for free standing installation

Abrir o catálogo na página 1

Grease separators – Everything specialists need to know Grease separators Reasons for installing a grease separation system Operations from small restaurants to large scale food processing plants disposing fats, oils and grease (FOGs) into public wastewater drainage systems are becoming an increasing concern to industry, government and environmental agencies. Wastewater travels a long distance from its original source to the wastewater treatment facilities. During this time large amounts of grease and food wastes build up in the drainage pipe systems leading to operational and public...

Abrir o catálogo na página 2

Grease separators – Everything specialists need to know For a clean environment When to use a grease separator ? Polyethylene grease separators – The long term solution …Easy transport Their low weight allows our grease separators to be transported easily by hand on site. A special base design also allows them to be transported by forklift truck. What can enter the separator ? Only wastewater containing organic FOG, which are required to be separated from the water, should be allowed into the separator. Under no circumstances should sewage, Grease separation chamber In the grease separation...

Abrir o catálogo na página 3

Grease separators -Everything specialists need to know Inlet piping Requirements made on the installation location Before a free-standing separator system can be installed, it must be checked that the planned set-up location is frost-free, has a horizontal, load-bearing floor, that there is sufficient space for set-up, operation, maintenance and control of the separator system and that the room is well vented and aerated. A water connection must be available for filling and cleaning the separator system as well as the respective electric installations required. When separator systems are to...

Abrir o catálogo na página 4

Grease separators -Everything specialists need to know Disposal pipe SonicControl The disposal pipe should be laid on a steady upward slope from the grease separator to the transfer point to the disposal vehicle, 90 degree elbows should be avoided. Disposal pipes should be executed as pressure or intake pipes in the necessary pressure level in accordance with the system features. Tight connections must be used for the individual pipes and fittings. Disposal pipes with a constant diameter should be laid to the transfer point. The intake pipe must have a nominal size of at least 0 65 mm....

Abrir o catálogo na página 5

Selection criteria Version G D D+S D+SP M+S PV+S

Abrir o catálogo na página 6

INFORMATION Do you require more detailed information ? Our Service Centre will be happy to help. You can find your personal KESSEL contact on page 5 of this catalog ! Complete System Solution In addition to individual grease- and oil separators, KESSEL also offers complete separator packages consisting of separator, properly matched lifting station and advantageous accessories. All from one source - KESSEL. Lifting and pumping stations for free standing and underground installation see chapter 3 “lifting stations”. Stainless steel drains and channels for kitchens and food processing plants...

Abrir o catálogo na página 7

KESSEL-Product information Polyethylene grease separators SmartSelect simply makes planning easier - calculation tool for separators at smartselect.kessel.com Grease separators made of polyethylene Grease separator EasyClean for free-standing set-up inside buildings COMPLETE SYSTEM SOLUTION In addition to individual grease separators, KESSEL also offers complete separator packages consisting of grease separator, properly matched lifting station and advantageous accessories. DRINKING WATER RINSING In order to avoid the formation of legionella, standard for Auto Mix & Pump version (PVS). The...

Abrir o catálogo na página 8

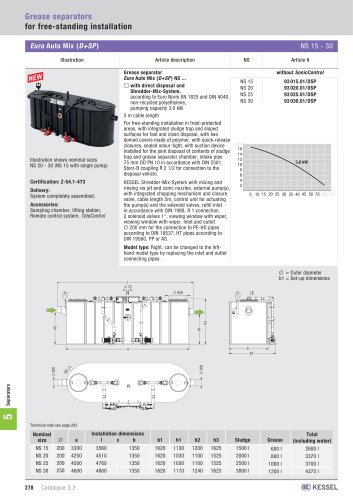

Grease separator Euro Grease separator Euro for free-standing set-up inside buildings SONIC CONTROL STRAIGHTFORWARD MAINTENANCE AND INSPECTION for the measurement, display and control of the grease layer thickness in a grease separator. Sloped arrangement of the tank openings permits better access. PLANNING MADE EASY ! Distinction between versions „in direction of flow right or left“ is no longer necessary. Direction of flow can be changed on site by changing inlet and outlet. In le t IMPROVED PLACEMENT THANKS TO THE CURVED SHAPE serves to comminute, mix and clean the tank content without...

Abrir o catálogo na página 9

Grease separators for free-standing installation EasyClean Auto Mix & Pump (PV+S)\ NS 2 - 10 Article description Certification: Z-54.1-474 Delivery: System completely assembled. Accessories: Sampling chamber, lifting stations, remote control, Telecontrol For free standing installation in frost protected areas, with integrated sludge trap, sloped interior base improves cleaning and reduces disposal time, inlet flow calming system and outlet flow regulation device, inlet and outlet interchangeable, slanted twin access covers with quick release odour tight snap closures, inspection window with...

Abrir o catálogo na página 10

Installation example EasyClean Auto Mix & Pump (PV+S) Professional advantages © Grease separator @ Shredder-Mix-System © Disposal line @ Connection for disposal truck © Remote control system (optional) © Sampling chamber © Lifting station ■ Program-controlled disposal and rinsing device ■ Shredder-Mix-System for homogenisation of the tank contents ■ 3.0 kW pump ■ Clean and odour-free disposal and cleaning ■ Optional remote control ■ Complete System Solution In addition to individual grease separators, KESSEL also offers complete separator packages consisting of grease separator, properly...

Abrir o catálogo na página 11

Grease separators for free-standing installation EasyClean Mix & Pump (M+S) NS 2 - 10 Article description NS Weight Article # Grease separator EasyClean Mix & Pump (M+S) NS ... ns □ according to Euro Norm EN 1825, NS manufactured from virgin, non-recycled NS polyethylene, pumping capacity 3.0 kW ns 5 m cable length ns Certification: Z-54.1-474 Delivery: System completely assembled. Accessories: Sampling chamber, lifting stations, Telecontrol For free standing installation in frost protected areas, with integrated sludge trap, sloped interior base improves cleaning and...

Abrir o catálogo na página 12Todos os catálogos e folhetos técnicos da KESSEL

-

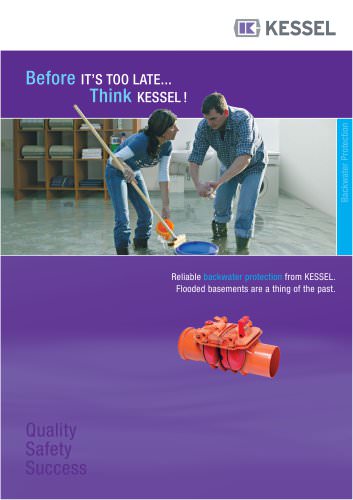

Backwater protection

12 Páginas

-

You can never improve the original.

16 Páginas

-

Backwater Valve

8 Páginas

-

Tailor-made

24 Páginas

-

Aqualift F XXL 400 V – 60 Hz

12 Páginas

-

Pump technology

58 Páginas

-

Hybrid drainage systems

24 Páginas

-

Drains-and-Channels

107 Páginas

-

Lifting-stations

69 Páginas

-

Hybrid-lifting-stations

19 Páginas

-

Backwater-Valves

41 Páginas

-

Catalogue3.2

326 Páginas

-

Euro Auto Mix & Pump (PV+S )

1 Páginas

-

Euro Mix & Pump (M+S )

1 Páginas

-

Euro Auto Mix (D+SP )

1 Páginas

-

Euro Mix (D+S )

1 Páginas

-

Euro Standard (D )

1 Páginas

-

Brochure avec références internationales

48 Páginas

-

Catalogue 3.1

310 Páginas

-

Drains and channels

112 Páginas

-

lifting stations

64 Páginas

-

Hybrid lifting stations

20 Páginas

-

Backwater protection

36 Páginas

-

Brochure Ecolift

8 Páginas

-

Brochure "Staufix"

8 Páginas

-

Brochure Ecolift XL

24 Páginas

-

Product Catalogue "Leading in Drainage 2.3"

229 Páginas

-

EasyClean Grease Separators

8 Páginas

-

Aqualift F XL Lifting Stations

8 Páginas

-

Aqualift F Compact

6 Páginas

-

Separators

30 Páginas

-

Parking deck drains

18 Páginas

-

Shower channels

15 Páginas

-

Bathroom drainss

15 Páginas

Catálogos arquivados

-

Reliable backwater protection

6 Páginas