Excertos do catálogo

UltraSTEEL® Greener by design. Stronger by design. PO Box 92, Downing St, Smethwick, West Midlands, United Kingdom B66 2PA Telephone: +44 (0) 121 555 1300 Fax: +44 (0) 121 555 1301 Email: ask.hadley@hadleygroup.co.uk While every precaution has been taken to ensure accurate presentation of information, The Hadley Group cannot be held responsible for any errors or omissions. We also reserve the right to change specification without prior notice. (10/2010)

Abrir o catálogo na página 1

Hadley Group Typical applications for UltraSTEEL® Global Patent Protection Helping you apply the UltraSTEEL® process

Abrir o catálogo na página 2

Hadley Group Winner of the Queens Award for Innovation The Hadley Group is one of the world’s leading manufacturers of cold rolled sections and products. We operate from purpose built premises in the United Kingdom, Dubai, Germany and Thailand, and are dedicated to the provision of matchless standards of service, quality, innovation and technical expertise. We carry out business on 5 continents with 36 countries. Winner of the Manufacturing Excellence Award The MANUFACTURING EXCELLENCE Awards Our continued investment in and the development of new roll forming technology has kept us at the...

Abrir o catálogo na página 3

Only through the application of our patented UltraSTEEL® process can you truly minimise your effect on the environment. Products manufactured using the UltraSTEEL® process will use less metal, which of course reduces the impact your business has on the environment. It also results in products that are lighter so you can ship more on each load, lowering transport related pollution too. But, lowering your environmental impact doesn’t stop there. We have an unrivalled knowledge of roll form engineering developed over 40 years and on thousands of products, plus internally developed engineering...

Abrir o catálogo na página 4

UltraSTEEL® is a cold rolled pre-forming process that locally work hardens the base metal. Because the process is applied to the standard base metal and in-line in the cold rolled forming process, it is does not increase manufacturing cost and is ideal for high volumes. In fact, over 1 billion metres of UltraSTEEL® product are manufactured each year by some of the world’s most respected brands. The metal is formed between mating rolls, which produce a dimpled pattern across the surface of the material. During the process, the effective thickness of the material is increased by locally...

Abrir o catálogo na página 5

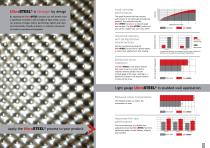

Improved memory and spring tension characteristics Sections manufacturing using the UltraSTEEL® process have a greater ability to return their original form after loading. Displacement (mm) Plain Steel Permanent Deformation Plain Steel A comparison between two samplesDeformation same original coil from the Permanent Deformation indicates a 31% reduction in permanent deformation. The UltraSTEEL® cross-section ensures that every screw is in contact with a material thickness greater that the nominal gauge of the steel, resulting in a significant increase in the torque required to strip-out the...

Abrir o catálogo na página 6

The simplicity and flexibility of the UltraSTEEL® process make it suitable for an incredibly wide range of applications, from construction profiles, through to automotive and high grade aerospace components. If you are interested in applying the UltraSTEEL® process please contact us by phone or e-mail. Tel: +44 (0) 121 555 1300 E-mail: ask.hadley@hadleygroup.co.uk Could you please provide the following information so that we can discuss your application in detail: • Name • Contact details • Company name • Product dimensions and or detailed drawings • Material required • Production volume...

Abrir o catálogo na página 7

Global Patent Protection Worldwide Manufacturing The UltraSTEEL® process is protected by global patents and is manufactured around the world by licensee holders and Hadley Group companies. Global Production Statistics • Over 1 Billion metres produced each year • Over 40,000 tonnes produced each year • Manufactured on over 300 mills worldwide apply the UltraSTEEL® Process Hadley Group Technology 5 (HGT) is unique in the world, a centre of excellence in cold roll-forming technology, product design and manufacture. It is the hub of all 6 technical knowledge for the Hadley Group and our...

Abrir o catálogo na página 8Todos os catálogos e folhetos técnicos da HADLEY

-

Hadley-Group-Industrial-Doors-Brochure

11 Páginas

-

BrickTie-leaflet

4 Páginas

-

Hadley-Group-UltraGrid-Brochure

16 Páginas

-

Fencing-Brochure

17 Páginas

-

SECTIONS FOR COMMERCIAL VEHICLES

4 Páginas

-

Bespoke steel profiles

36 Páginas

-

HADLEY UltraZED2 - HADLEY UltraBEAM2

76 Páginas

-

Hadley steel framing

27 Páginas

-

BRIDGE STEEL SECTIONS LIMITED

4 Páginas

-

Industrial doors

9 Páginas

-

Hi 30

2 Páginas

-

UltraSTRUT?

4 Páginas

-

UltraMEZZ®

16 Páginas

-

Purlins and Slide Rail Systems

68 Páginas

Catálogos arquivados

-

HADLEY STEEL FR AMING

24 Páginas

-

UltraBEAM

28 Páginas

-

CABLE MANAGEMENT

28 Páginas

-

CURVED CORRUGATED

2 Páginas

-

COUNTRY-CLAD

2 Páginas

-

INDUSTRIAL DOORS

4 Páginas

-

UltraFENCE

4 Páginas

-

Steel Framing

24 Páginas

-

Purlings

65 Páginas

-

CEILING SYSTEM

27 Páginas

-

UltraSHEET

2 Páginas

-

UltraSTEEL

4 Páginas

-

UltraBar

4 Páginas