Catalog excerpts

The MCI Technologies Company From technical insulation to phase change materials... Since its foundation in 1988 MCI Technologies has been manufacturing technical insulation for the industry. In 2008 the company started a comprehensive program of research and development on microencapsulated Phase Change Materials (PCM). It developed a range of microcapsules, called INERTEK, dedicated to various industrial applications: building, textile, transport, etc... The current production capacity reaches several tons of microcapsules per week. Since 2012, WINCO Technologies has been marketing the...

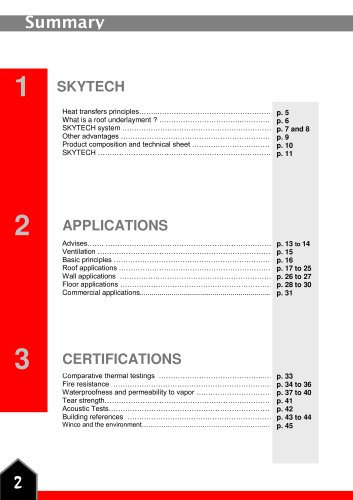

Open the catalog to page 2

INERTEK Microcapsules Description The principle of microencapsulation is to form a resistant envelope around phase change material microparticles. INERTEK microcapsules, with a size ranging from 5 to 25 µm, can be incorporated into other products: coatings, plasterbooards, insulation, technical textiles, etc... INERTEK Microcapsules are available in 2 forms: Powder or Slurry. x 1000 Magnification of INERTEK microcapsules Manufacturing process INERTEK microcapsules are produced by in situ polymerization. This process is repeatable on a wide spectrum of internal phases: phase change materials...

Open the catalog to page 3

The Benefits of INERTEK Microcapsules • A wide range of melting temperatures The INERTEK range includes 9 references, with melting temperatures ranging from 5 °C to 70 °C. Other phase change materials (customization of the phase change range) can be microencapsulated on request. • A high latent heat MCI Technologies selected for its INERTEK microcapsules range, pure internal phases with high latent heat. Microcapsules INERTEK offer a high thermal performance and ease of integration into other products. Increased lifespan The internal phases used in the INERTEK microcapsules have stable...

Open the catalog to page 4

Main rangePhase change range Product Latent heatMelting aera Solidification aera

Open the catalog to page 5

INERTEK 5 Phase change range Heat storage capacity* Product Melting aera Solidification aera Powder 5 - 6 °C 0 - (-2) °C 215 J/g (60 Wh/kg) * combination of latent heat and sensible heat in a temperature range of (-10) - 10 °C Slurry : INERTEK 5 S Enthalpy distribution (3°C/h) Partial enthalpy (J/g) Powder : INERTEK 5 P Enthalpy distribution (3°C/h) Partial enthalpy (J/g)

Open the catalog to page 6

INERTEK 21 Phase change range Product Melting aera INERTEK 21 Heat storage capacity* 165 J/g (46 Wh/kg) * combination of latent heat and sensible heat in a temperature range of 5 - 25 °C Slurry : INERTEK 21 S Enthalpy distribution (3°C/h) 76

Open the catalog to page 7

Phase change range Melting aera Solidification aera Heat storage capacity* combination of latent heat and sensible heat in a temperature range of 10 - 30 °C Enthalpy distribution (3°C/h) I Melting l Solidification Powder: INERTEK 23 P Enthalpy distribution (3°C/h) I Melting I Solidification

Open the catalog to page 8

INERTEK 26 Phase change range Melting aera Solidification aera Heat storage capacity* combination of latent heat and sensible heat in a temperature range of 15 - 35 °C

Open the catalog to page 9

Quality MCI Technologies is ISO 9001 certified. A quality monitoring plan was implemented on the INERTEK microcapsules. Three main types of checks are carried out: The distribution of INERTEK microcapsules sizes is controlled during and at the end of the manufacturing, in order to ensure that it complies with our customers requirements. • DSC (Differential scanning calorimetry) The thermal performance constancy of INERTEK microcapsules is checked by performing a DSC measurement on each production batch. To ensure their lifespan, INERTEK microcapsules are subject to a double ageing protocol:...

Open the catalog to page 10

Laboratory ageing INERTEK 23 S example : Ageing carried out by calorimeter, including 1000 cycles composed of 2 segments: • 3 ° C/min heating from 6 to 33 ° C. • 3 ° C/min cooling from 33 to 6 ° C. Temperature (°C) ■ 10 cycles ■ 100 cycles ■ 1000 cyles Thermal chamber ageing under real use conditions ••• • •••• , •••••• MCI Technologies recommends to its customers another type of ageing: ageing on finished products in a climate chamber. For this, we provide our customers with a thermal chamber to simulate ageing under real use m * conditions of products integrating INERTEK microcapsules.

Open the catalog to page 11

Product Development Support MCI Technologies offers to its customers technical support to assist them in the development of products incorporating INERTEK microcapsules. • Formulation support • Qualification support • Products ageing follow-up • Thermal study MCI Technologies uses dynamic thermal simulation softwares like TRNSYS and Design Builder allowing phase change materials modeling.

Open the catalog to page 12

If MCI Technologies is specialized in the microencapsulation of phase-change materials, it also offers: • Integration of phase-change materials in the form of pellets. • Integration of phase-change materials into hermetic containers : macroencapsulation.

Open the catalog to page 13

177 Cl technologies MCI technologies Z.I. des Chatelets - 8 rue du Boisillon 22950 TREGUEUX - France Phone : +33 (0)2 96 78 24 24 contact@mci-tech.com www.mci-tech.com

Open the catalog to page 14All WINCO TECHNOLOGIES catalogs and technical brochures

-

SKYTECH PRO XL

6 Pages

-

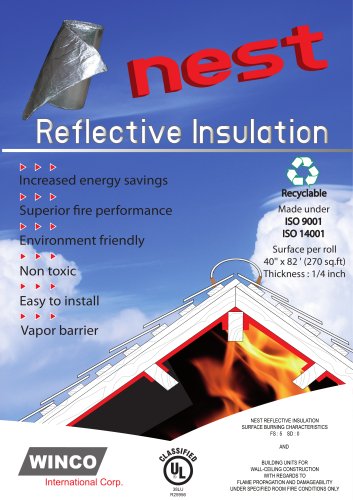

NEST - RECTO

6 Pages

-

NEST

4 Pages

-

SKYTECH PRO

6 Pages

-

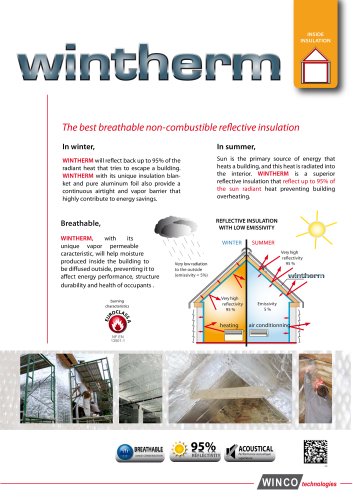

wintherm

2 Pages

-

APPLICATIONS SKYTECH PRO

44 Pages

Archived catalogs

-

nest

4 Pages