Catalog excerpts

Universal Ventless Hood MODEL ❏ WVU-72 Cooking Appliances – Only electrically heated appliances are acceptable for installation. Cooking equipment is optional from Wells or other manufacturers. Appliances must be installed as per manufacturers instructions and controlled thru the hood equipment shut-off interface through a customer supplied contractor which will disable cooking equipment in the event of fire or hood malfunction. For size, temperature and KW limits see back page or manual. Exhaust and Air Flow – Exhaust air may be horizontal or vertical. Hoods are shipped for vertical discharge and are field convertible for horizontal discharge. Typical airflow is 3,000 CFM. A minimum of 1,600 cubic feet of fresh air per minute is recommended both in and out of the cooking area to ensure the dilution of cooking aromas. STANDARD FEATURES Model WVU-72 (equipment sold separately) DESCRIPTION Wells Universal hoods are Certified Type-1 compliant, UL710B approved recirculation hood systems and feature completely self-contained air filtration and fire-suppression systems. They do not require venting outside making it possible to cook in nontraditional locations or when traditional Type-1 hoods and ductwork are impractical, restricted or too expensive. Operators can mix and match various electric cooking equipment under the hood such as fryers, ovens, griddles, steamers and more - providing greater flexibility and through-put. SPECIFICATIONS Fire Protection – Completely self contained ANSUL® R-102 system includes ANSUL® tank, nitrogen cartridge, ANSUL® sopanifier, piping, heat sensors, ANSUL® drops, nozzles, and movable manual pull station. Manual pull can be relocated to the egress position or an additional station can be added by an authorized ANSUL® representative. Front access for easy fire system maintenance. Fire protection system meets NFPA 96 Chapter 13. Fire protection system must be charged and certified by ANSUL® Authorized distributor after installation and before first use (operator’s responsibility). Filtration – Completely self-contained filtration process reduces emissions below that allowed in NFPA 96 and ANSI UL710B using the EPA 202 test method and includes stainless steel grease baffle filter with grease cup, fiberglass pre-filters, HEPA (High-Efficiency Particulate Air) filter/ carbon-charcoal filter pack. All filters are easily removable with out tools. Air flow sensors continually monitor air flow optimizing performance and grease removal while an interlock system will not allow cooking appliances to function if filters are missing, clogged or in the event of a fire. ❏ Completely self-contained, 4-stage filtration system ❏ Completely self-contained fire protection system ❏ Very quiet with only 70 dBA average ❏ Interlock system will disable cooking appliances if filters are missing, clogged or in the event of a fire ❏ Airflow sensors continually monitor airflow for optimizing performance and grease removal ❏ Illuminated early-warning system to monitor filter replacement ❏ Completely self-contained filtration process reduces emissions below that allowed in NFPA 96 and ANSI UL710B using the EPA 202 test method ❏ Four LED lights producing 500 lumens each for improved visibility - light color temperature (cool white): 6000K ❏ Stainless steel construction for strength, durability and ease of cleaning ❏ Fits through a 36” wide door opening ❏ 6” to 8” adjustable legs (adjustable by 2” for leveling) ❏ Universal systems are movable making them ideal for leased properties ❏ Available in 208/240V, 1Ø ❏ Limited one-year parts and one year labor warranty OPTIONS & ACCESSORIES ❏ Pre-filters ❏ 10” to 12” adjustable legs (adjustable by 2” for leveling) ❏ HEPA / carbon-charcoal filter packs CERTIFICATIONS UL710B CATEGORY YZCT RECIRCULATING SYSTEM FILE NO. MH48408 Wells Manufacturing · 265 Hobson Street, Smithville, Tennessee 37166 U.S.A. Phone : (314) 678-6314 · Fax (314) 781-3636 www.wells-mfg.com · Printed in the U.S.A.

Open the catalog to page 1

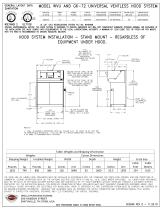

GENERAL LAYOUT DATA SANITATION MODEL WVU AND GK-72 UNIVERSAL VENTLESS HOOD SYSTEM VOLTAGE AC 60 HZ NSF/ANSI 2 UL710B UL CAT. YZCT RECIRCULATING SYSTEM FILE NO. MH48408SPECIAL ENVIRONMENTAL NOTICE: THE HOOD SYSTEM IS DESIGNED TO REDUCE EMISSIONS BUT WILL NOT COMPLETELY ELIMINATE COOKING AROMAS. AIR EXCHANGE AT THE INSTALLATION SITE MUST COMPLY WITH REQUIREMENTS OF THE LOCAL JURISDICTIONAL AUTHORITY. A MINIMUM OF 1200 CUBIC FEET OF FRESH AIR PER MINUTE INTO THE AREA IS RECOMMENDED TO ENSURE ADEQUATE DILUTION.HOOD SYSTEM INSTALLATION - STAND MOUNT - REGARDLESS OF EQUIPMENT UNDER HOOD. Table:...

Open the catalog to page 2

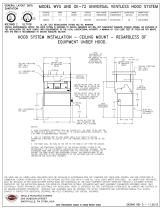

GENERAL LAYOUT DATA SANITATION MODEL WVU AND GK-72 UNIVERSAL VENTLESS HOOD SYSTEM VOLTAGE AC 60 HZ NSF/ANSI 2 UL710B UL CAT. YZCT RECIRCULATING SYSTEM FILE NO. MH48408SPECIAL ENVIRONMENTAL NOTICE: THE HOOD SYSTEM IS DESIGNED TO REDUCE EMISSIONS BUT WILL NOT COMPLETELY ELIMINATE COOKING AROMAS. AIR EXCHANGE AT THE INSTALLATION SITE MUST COMPLY WITH REQUIREMENTS OF THE LOCAL JURISDICTIONAL AUTHORITY. A MINIMUM OF 1200 CUBIC FEET OF FRESH AIR PER MINUTE INTO THE AREA IS RECOMMENDED TO ENSURE ADEQUATE DILUTION.HOOD SYSTEM INSTALLATION - CEILING MOUNT - REGARDLESS OF EQUIPMENT UNDER HOOD. THE...

Open the catalog to page 3

ALL MODELS - UNIVERSAL VENTLESS HOOD SYSTEM HOOD SYSTEM INSTALLATION - CEILING MOUNT - REGARDLESS OF EQUIPMENT UNDER HOOD. CAUTION! - IF THE INSTALLATION IS A CEILING MOUNT, THE CEILING STRUCTURE MUST BE ABLE TO SUPPORT THE WEIGHT OF THE HOOD. THE STRUCTURAL INTEGRITY OF THE CEILING, AND THE CEILING MODIFICATIONS THAT ARE REQUIRED MUST BE DETERMINED BY A STRUCTURAL ENGINEER. THIS IS THE RESPONSIBILITY OF THE INSTALLATION CONTRACTOR. CEILING MOUNT DETAIL (NOT SUPPLIED) THE HOOD AND ALL UNDER HOOD APPLIANCES MUST BE INSTALLED IN ACCORDANCE WITH THE STANDARD FOR VENTILATION CONTROL AND FIRE...

Open the catalog to page 4

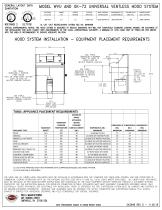

GENERAL LAYOUT DATA SANITATION MODEL WVU AND GK-72 UNIVERSAL VENTLESS HOOD SYSTEM VOLTAGE AC 60 HZ SEE TABLE DIMENSION C MINIMUM. FROM INSIDE WALL DE HOOD SKIRT (EITHER SIDE) TD EDGE OF HEATED COOKING SURFACE HEATED SURFACE (IN CASE OF FRYER, THIS IS THE OIL FILL HEIGHT) 72.0 SPACE FOR UNDER HDDD APPLIANCES SEE TABLE MAXIMUM SINGLE APPLIANCE HEATED CDDKING SURFACE WIDTH (1) LID OF THE APPLIANCE MUST NOT INTERFERE WITH SUPPPRESSION NOZZLE DISCHARGE PATTERN. (2) PLUS OVEN KW IF APPLICABLE THE HOOD AND ALL UNDER HOOD APPLIANCES MUST BE INSTALLED IN ACCORDANCE WITH THE STANDARD FOR VENTILATION...

Open the catalog to page 5All Wells Bloomfields catalogs and technical brochures

-

Cook & Hold Warmers

2 Pages

-

VCS 2000

2 Pages

-

WVOG136

2 Pages

-

WVO2HFG - WVO2HSG

2 Pages

-

WVU-72

2 Pages

-

WVU-48

2 Pages

-

WVU-26

2 Pages

-

TEA-DISPENSERS

2 Pages

-

THERMAL SERVERS

2 Pages

-

COUNTERTOP GAS GRIDDLES

28 Pages

-

HEAVY DUTY GAS GRIDDLE

32 Pages

-

OWNERS MANUAL

40 Pages

-

RW SERIES DRAWER WARMERS

4 Pages

-

WB-1, WB-2

2 Pages

-

WELLS - Ventless Hoods

7 Pages

-

WELLS - Hot/Cold

8 Pages

-

High Production Open Fryer

2 Pages

-

Oil Disposal Caddy

2 Pages

-

Soup Cookers:SC6411

2 Pages

-

Heated Dispensers:HD8799

2 Pages

-

Countertop Char Broilers:B40

2 Pages

-

Countertop Griddles:HDG2430G

2 Pages

-

Frost Tops:FT-1_FT-6

2 Pages

-

Dual Pot Fryers F676-208

2 Pages

-

Built-In Griddles:JG246UL

2 Pages

-

ventless coocking systems

6 Pages

-

Ventless Fryers:WVAE30F

2 Pages

-

2012 price list

80 Pages

Archived catalogs

-

Suggested List Price 2009

80 Pages

-

Bloomfields brochure

24 Pages