Catalog excerpts

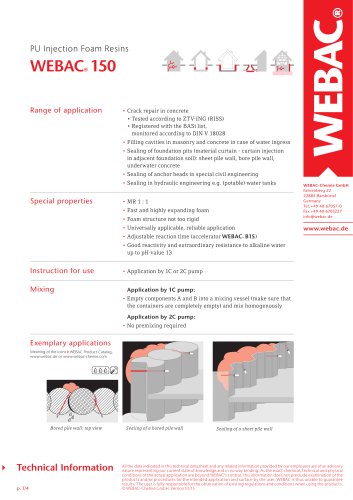

PU Injection Foam Resins Range of application PU Injection Foam Resins • Crack repair in concrete • Tested according to ZTVING (RISS) • Registered with the BASt list, monitored according to DIN V 18028 • Filling cavities in masonry and concrete in case of water ingress • Sealing of foundation pits (material curtain curtain injection in adjacent foundation soil): sheet pile wall, bore pile wall, underwater concrete • Sealing of anchor heads in special civil engineering • Sealing in hydraulic engineering e.g. (potable) water tanks Special properties • MR 1 : 1 • Fast and highly expanding foam • Foam structure not too rigid • Universally applicable, reliable application • Adjustable reaction time (accelerator WEBAC B15 ) p. 20) ® • Good reactivity and extraordinary resistance to alkaline water up to pHvalue 13 • Application by 1C or 2C pump Application by 1C pump: • Empty components A and B into a mixing vessel (make sure that the containers are completely empty) and mix homogenously Application by 2C pump: • No premixing required Exemplary applications Meaning of the icons WEBAC Product Catalog, www.webac.de or www.webac-chemie.com Bored pile wall: top view Sealing of a sheet pile wall All the data indicated in this technical data sheet and any related information provided by our employees are of an advisory nature representing our current state of knowledge and in no way binding . As the exact chemical, technical and physical conditions of the actual application are beyond WEBAC‘s control, this information does not preclude examination of the products and/or procedures for the intended application and surface by the user . WEBAC is thus unable to guarantee results . The user is fully responsible for the observation of existing regulations and conditions when using the products . Sealing of a bored pile wall All the data indicated in this technical data sheet and any related information provided by our employees are of an advisory nature representing our current state of knowledge and in no way binding. As the exact chemical, technical and physical conditions of the actual application are beyond WEBAC‘s control, this information does not preclude examination of the products and/or procedures for the intended application and surface by the user. WEBAC is thus unable to guarantee results. The user is fully responsible for the observation of existing regulations and conditions when using the products. © WEBAC-Chemie GmbH. Version 01/15

Open the catalog to page 1

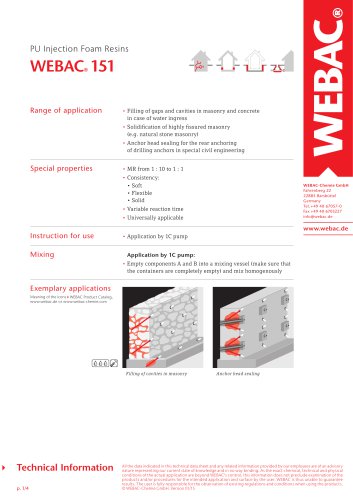

PU Injection Foam Resins Preparatory work Mixing Application Final work Cleaning Storage Occupational safety PU Injection Foam Resins Mixing ratio Apparent density of foam Density, 20 °C (ISO 2811) Processing life (WEBAC test specification following ISO 9514) • Crack repair in concrete Values • Tested according to ZTVING (RISS) 1 : 1 BASt list, • Registered with the parts by volume monitored according to DIN V 18028 3 • Filling cavities in masonry and concrete in case of water ingress Comp. A 1.0 g/cm • Sealing of foundation pits3 (material curtain curtain injection 1.2 g/cm3 Comp. B in...

Open the catalog to page 2

General Information WEBAC PU Injection Foam Resins PU injection foam resins (SPU) are designed for quickly and temporarily stopping water. They are characterized especially by their strong increase in volume and can also be used in case of highly pressing water, e.g. in dam building, tunnel construction, bridge building and special civil engi neering. The products are compatible with concrete, steel, foil, cable sheathing and WEBAC injection materials. WEBAC PU injection foam resins are resistant to salts, lyes and acids in concentrations usually found in buildings and structures. A...

Open the catalog to page 3

General Information WEBAC PU Injection Foam Resins To ensure durable limited-flexibility filling and sealing of cracks, a secondary injection with WEBAC PU injection resins is necessary depending on the object. Immediately after the injection of WEBAC PU injection foam resins, the secondary injection can usually be carried out via the same drill-hole packers. However, if the secondary injection is carried out several hours later it may be necessary to install new drill-hole packers in different positions. • Observe the technical data sheets of the injection pumps and cleaners used • Refer...

Open the catalog to page 4