Catalog excerpts

BRICKS & BRICK SOLUTIONS

Open the catalog to page 1

WHY BRICKS? Bricks are a warm and noble natural product. In addition, this environment-friendly and durable building material lasts for a long time. A very long time; up to more than 100 years. And contrary to other materials, a brick wall is very user and maintenance friendly. Of course, an architect already knows all this. We will quickly list the advantages of bricks for you: • resistant against high pressure and frost; • does not shrink and expand during fluctuation of temperature; • can absorb heat very well; • is reusable and recyclable; • is available in many colours and textures ....

Open the catalog to page 2

45 Lithium - Architect: A2O architecten, Hasselt (BE)

Open the catalog to page 3

FACTORS THAT DETERMINE THE APPEARANCE OF THE FAÇADE 1. the colour of the facing brick; 2. the visible surface texture of the facing brick; 3. the size or sizes of the facing bricks; 4. the brickwork bond; 5. the colour of the joint (if there is one); 6. the type of joint (if there is one); 7. combinations with other materials (if there are any). This tab will discuss in further detail the various possibilities. 45 Lithium - Architect: Stramien cvba, Antwerpen (BE) 533 Morvan Zwart - Architect: Unknown

Open the catalog to page 4

Where does the colour of a brick come from? The colour of the chosen facing brick is a decisive factor in determining the look of the façade. In case of glued masonry, that colour becomes the pure colour of the facing brick. But do the colours of the bricks come from? There are several factors that determine the colour: colour nuances as a result of the baking process (oxidising or reducing); the colour of the fired clay mixture (the colour of the brick’s heart); the colour of the sand or encobe (thin layer of clay) fired into the surface; Our brickmakers work with the elements that nature...

Open the catalog to page 5

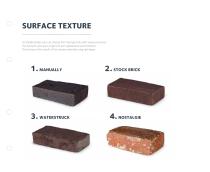

SURFACE TEXTURE At Vandersanden you can choose from facing bricks with various textures. The textures give your project its own appearance and character. The texture is the result of the chosen manufacturing technique.

Open the catalog to page 6

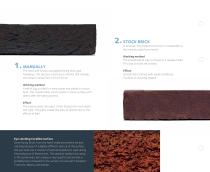

The most well-known and applied facing brick type. Nowadays, this process is done by a machine that imitates the ancient manual form of brick forms. Working method A ball of clay is rolled in a sand carpet and placed in a stock brick. This creates folds, which results in a brick surface with grains after the baking process. Effect This texture gives the colour of the facing brick more depth and style. The grains create fine lines of shadow due to the effects of light. Eye catching Coralline surface Some facing bricks from the hand-made assortment are eyecatching because of a slightly...

Open the catalog to page 7

A unique moulding technique of which the name hints to the use of sprayed water. Working method The ball of clay is not rolled in sand but placed in a nonsanded mould. In advance, this mould is sprayed wet. This way the unfired brick can be taken out of the mould. Effect A bit of accumulated air between the clay ball and the wall of the stock brick create a slight texture on the surface. The brick is relatively smooth and shows less grains. A patented mould process of Vandersanden. Working method In principle, it is a finishing to the manual mould technique. After the drying process, the...

Open the catalog to page 8

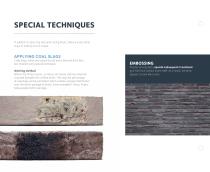

special techniques In addition to texturing and sand-facing bricks, there are also other ways of making a brick unique. applying coal slags Coals slags, which are typical for old and traditional brick kilns, are imitated using special techniques. Working method Before the firing process, a mixture of natural starting materials is spread between the unfired bricks. This way the percentage of coal slags can be controlled, which creates a proper distribution over the entire package of bricks. Some examples? Vecto, Kripto, Salvia applied with coal slags. Precise carving and a special subsequent...

Open the catalog to page 9

applying encobe (thin layer of clay) Encobes are pigments that mostly consist of clay minerals and oxides. Working method Mixing in water creates a liquid mass. A thin layer of this substance is sprayed on the unfired bricks with special sprinkler nozzles. In the oven these encobes sinter to the surface. Encobe stains can partially or entirely cover the brick surface. They exist in all the colours of the rainbow. Project: Applying Cameo encobe, Isala clinic, Zwolle (NL) Architect: Alberts & Van Huut B.V., Amsterdam (NL)

Open the catalog to page 10

SIZES The size is very determining for the appearance of a façade. The larger the size, the larger the share of the bricks in proportion to the joint mortar. And the other way around. Most colours in the assortment of Vandersanden Group facing bricks are available in the following sizes: M50 ± 190 x 90 x 50 mm (± 83 pieces per m²) ‘Waal’ size (WS) ± 210 x 100 x 50 mm (± 72 pieces per m²) M65 ± 190 x 90 x 65 mm (± 66 pieces per m²) Thick size (TS) ± 210 x 100 x 65 mm (± 58 pieces per m²) NS ± 240 x 115 x 70 mm (± 48 pieces per m²) ZERO ± 204 x 100 x 50 mm (± 90 pieces per m², masonry without...

Open the catalog to page 12

Tip The ‘Waal’ size makes buildings seem wider. This size emphasises the horizontal aspect of the brick and the building. This is interesting for projects on small building grounds or projects in which this kind of effect enhances the architecture of a building. 72 Treviso - Architect: Loof & van Stigt Architects, Amsterdam (NL) Tip Vandersanden Group also offers profile bricks. These are facing bricks with a special design. For example, curved bricks, bricks with an angle of 135°, bricks with rounded corners, etc. The linear measures of such bricks vary and depend on the specific...

Open the catalog to page 13

BRICKWORK BONDS The way in which a brick is laid – the brickwork bond – also strongly influences the appearance of the façade. A well thoughtout brickwork bond gives your project extra style and character. Brickwork bonds not only have an aesthetic effect; The choice in brickwork bond can also influence the budget. More complicated bonds, which usually necessitate more grinding work, can substantially raise the price. 533 Morvan Zwart - Architect: Unknown

Open the catalog to page 14All Vandersanden Group catalogs and technical brochures

-

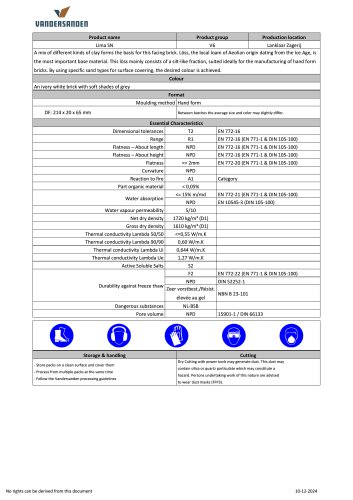

Lima SN

1 Pages

-

Waterstruck bricks

11 Pages

-

Zero Inspiration

11 Pages

-

Vandersanden Bricks Inspiration

25 Pages

-

Vandersanden Bricks Wasserstrich

11 Pages

-

Brick slips

9 Pages

-

THE SIGNA

20 Pages

-

ZERO

16 Pages

-

E-Brick

16 Pages