Catalog excerpts

Ceiling diffusers Type DLQL For clear room heights to approximately 4.0 m

Open the catalog to page 1

Contents · Description Description __________________________________ Construction · Dimensions ______________________ Installation __________________________________ Directions of discharge ________________________ Nomenclature ________________________________ Quick selection ______________________________ DLQL...-H for side entry Ceiling diffusers Type DLQL provide a comfortable air conditioning of rooms. The horizontal discharge takes place with high induction, which results in a rapid decay of supply air velocity and temperature differential over a short distance from the diffuser....

Open the catalog to page 2

Construction · Dimensions Characteristics – For supply or extract air – Side or top entry spigot – Recommended supply air temperature difference up to ±10 K Construction features – Face plate made of perforated sheet metal for fitting into T-bar ceilings (T) or central fixing screw fastening for installation into grid or plasterboard ceilings (P) – Supply air construction with baffle plate – Spigot connection suitable for circular ducts according to EN 1506 or EN 13180 – Option with groove for lip seal – Additional blanking plates to provide various air discharge directions – Face plate...

Open the catalog to page 3

Installation The customer must install the ceiling diffusers, make all connections, and provide the hanging system, connection and sealing materials. Only trained expert personnel should install and make the appropriate connections. All legal regulations for site work must be complied with. The plenum box (side entry) has four suspension holes and the casing (top entry) has four hanging brackets for suspending the diffuser from the ceiling slab. Use only certified hanging systems. Installation into grid and plasterboard ceilings The face plate of the ceiling diffuser (DLQL-P) is attached to...

Open the catalog to page 4

Directions of discharge Without blanking plates, the air is discharged horizontally and evenly on all sides (four-way). Alternative air discharge directions can be achieved with blanking plate accessories. A maximum of three blanking plates are placed in the ceiling diffuser. They can be arranged in any manner. Extract air ceiling diffusers have no blanking plates. Blanking plate Air discharge three way with one blanking plate Air discharge two way with two blanking plates Air discharge two way with two blanking plates Air discharge one way with three blanking plates

Open the catalog to page 5

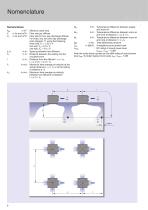

Nomenclature Nomenclature in m² : Effective outlet area in l/s and m³/h : Flow rate per diffuser in l/s and m³/h : Flow rate for four way discharge diffuser For three, two and one way discharge enter diagram 11 using the following: three way: V₄ = 1,33 × V two way: V₄ = 2,0 × V one way: V₄ = 4,0 × V a, b in m : Spacing between two diffusers h₁ in m : Distance between the ceiling and the occupied zone l in m : Distance from the diffuser l = x + h₁, l = a ⁄ 2 or l = a ⁄ 2 + h₁ vl in m/s : Maximum time average air velocity at the wall at distance l = x + h₁ or at the ceiling at distance a ⁄ 2...

Open the catalog to page 6

Quick selection Supply air, top entry Vmin Nominal size Nominal size Nominal size Nominal size Nominal size Nominal size Nominal size Note the noise levels quoted are the dBA rating of sound power level LWA. To obtain typical room levels LPA ≈ LWA − 5 dB. Extract air, side connection Nominal size Extract air, top connection Nominal size Nominal size Supply air, side entry

Open the catalog to page 7

Acoustic data Supply air, top entry Example 1 Result of selection: ∆pt = 22 Pa (from Diagram 4) LWA = 38 dB(A) (from Diagram 4) Given: Office Room width: 5.60 m Room depth: 2.80 m Room height: 3.00 m Total supply air flow rate to room: 200 l/s (720 m³/h) Two ceiling diffusers, discharge four way, top entry Flow rate per diffuser: 100 l/s (360 m³/h) Required sound power level per diffuser: 40 dB(A) For the aerodynamic data, see the continuation on page 11 Quick Selection: See page 7. DLQL...-V.../400 91 l/s at 35 dB(A) DLQL...-Z-V, discharge three way Size 250 Total differential pressure ∆pt...

Open the catalog to page 8

Acoustic data Supply air, side entry LWA = 39 dB(A) (from Diagram 8) Correction according to table 39 dB(A) + 1dB = 40 dB(A) Given: Office Width: 5.60 m, depth: 2.80 m, height: 3.00 m Total supply air flow rate to room: 200 l/s (720 m³/h) Two ceiling diffusers, discharge four way , side entry Take a flow rate control damper setting up to 45° into consideration. Flow rate per diffuser: 100 l/s (360 m³/h) Required sound power level per diffuser: 40 dB(A) Influence of flow rate control damper Correction values for diagrams 5 to 8 DLQL...-Z-H, discharge three way Size 250 Total differential...

Open the catalog to page 9

Acoustic data Extract air Given: Office Extract air flow rate: 200 l/s (720 m³/h) Required sound power level: 40 dB(A) One ceiling diffuser, top connection Quick Selection: DLQL...-V.../400 209 l/s at 35 dB(A) Influence of flow rate control damper Nominal size Correction values for diagram 10 45° Total differential pressure ∆pt in Pa Total differential pressure ∆pt in Pa Sound power level and total differential pressure Result of selection: ∆pt = 26 Pa (from Diagram 9) LWA = 34 dB(A) (from Diagram 9)

Open the catalog to page 10

Aerodynamic data Continuation of Examples 1 and 2 Between two diffusers: a⁄2 = 2.8 ⁄ 2 = 1.4 m vl = 0.45 m/s from Diagram 11 vh1 = 0.15 m/s from diagram 13 a ⁄ 2 + h₁ = 1.4 + 1.2 = 2.6 m ∆tl ⁄ ∆tZ = 0.11 from Diagram 12 Given: Spacing between two diffusers: a = 2.8 m Distance between the ceiling and the occupied zone: h₁ = 1.2 m Distance to wall: x = 1.40 m Result of selection: Flow rate for discharge four way V4 = V = 100 l/s At the wall: l = x + h₁ = 1.4 + 1.2 = 2.6 m vl = 0.27 m/s from Diagram 11 ∆tl ⁄ ∆tZ = 0.11 from Diagram 12 Nominal size Temperature quotient Air velocity vh1 between...

Open the catalog to page 11

Order Details Specification text* Sound power level of the air-regenerated noise measured in accordance with EN ISO 5135. Materials Face plate made of galvanised perforated sheet steel; casing, sheet metal covers, plenum box, and flow rate control damper made of galvanised sheet steel. Baffle plate made of acoustic non woven composite material. Face plate powder-coated white (RAL9010) or another colour. Casing painted black (RAL 9005). Black baffle plate. Ceiling diffuser options: – Frameless construction, suited for conventional T-bar ceilings. – Plenum box with flow rate control damper...

Open the catalog to page 12All TROX catalogs and technical brochures

-

Retrofit kits

6 Pages

-

X-GRILLE Cover

18 Pages

-

QUICK SELECTION GUIDE 2019 - 2

804 Pages

-

QUICK SELECTION GUIDE 2019 - 1

530 Pages

-

ATVC-100

8 Pages

-

X-CUBE Compact

12 Pages

-

X-CUBE RUN AROUND COIL SYSTEM

10 Pages

-

Air-water systems

307 Pages

-

ARR

2 Pages

-

WT · WL · EL

8 Pages

-

VMRK

4 Pages

-

VFR

8 Pages

-

Tunnel dampers

20 Pages

-

FKS-EU

20 Pages

-

CAK

6 Pages

-

Type ST · XT

8 Pages

-

Type ARK · ARK1

8 Pages

-

Type NL

8 Pages

-

Type JZ · JNE · JZ-L · JZD-G

20 Pages

-

Type FSL-B-ZAB

4 Pages

-

Type PKV

7 Pages

-

Type BID

8 Pages

-

Type QLI

8 Pages

-

TVJ-Easy/TVT-Easy

12 Pages

-

LVC

9 Pages

-

RM-O-3-D

7 Pages

-

RM-O-VS-D

7 Pages

-

FK-EU

56 Pages

-

EK-01

14 Pages

-

XSA

12 Pages

-

MSA

12 Pages

-

SCHOOLAIR-V

12 Pages

-

SCHOOLAIR-B

12 Pages

-

FSL-B-SEK

4 Pages

-

DID632

20 Pages

-

DID300B

12 Pages

-

DID312

16 Pages

-

AGW

24 Pages

-

AGS

24 Pages

-

DLQ-1...4-AK

13 Pages

-

DQ/ADQ

9 Pages

-

DLQ/ADLQ

10 Pages

-

DLK-Fb

4 Pages

-

VD

10 Pages

-

QSH · ISH

8 Pages

-

X-CUBE

16 Pages

-

FV-K90

12 Pages

-

TVR-Ex _ TES/TEF

7 Pages

-

AK-Ex

5 Pages

-

JZ-RS

5 Pages

-

FKRS-EU

28 Pages

-

Multileaf Dampers

8 Pages

-

Star Climate

16 Pages

-

X-GRILLE-Basic

4 Pages

-

X-GRILLE-Basic

3 Pages

-

Jet nozzles TJN

3 Pages

-

ARCHITECTURE NEEDS TO BREATHE

16 Pages

-

SD

10 Pages

-

AIRNAMIC

12 Pages

-

XARTO

12 Pages

-

X-CUBE COMPACT

10 Pages

Archived catalogs

-

Displacement Flow Diffusers

32 Pages

-

Product Summary

7 Pages

-

Quick selection guide

48 Pages

-

Air-water systems Design manual

60 Pages

-

Slot Diffuser

11 Pages

-

Passive Chilled Beams

7 Pages

-

Swirl Diffusers

17 Pages

-

Grilles/Linear Grilles

24 Pages

-

Swirl Diffusers Type FDE

6 Pages

-

Swirl Diffuser Type VDW

20 Pages

-

The art of handling air

80 Pages