Catalog excerpts

Evolution - Limited Use/Limited Application Low Rise Elevator PART 1 — GENE RAL 1.01 S ection Includes: Limited Use/Limited Application (LU/LA) commercial elevator with 1:2 roped hydraulic lift system. 1.02 W ork Included: Furnish all labor and materials, equipment and incidentals necessary to assemble and erect the commercial elevator. 1.03 W ork by Others: A. C onstruct a hoistway of the size required by the manufacturer. B. C onstruct a machine room. C . P rovide system to maintain hoistway and machine room temperature between 50-90 degrees Fahrenheit. D . P rovide electrical power per the manufacturer and the approved drawings. 1.04 References: A. ASME /ANSI A17.1 “Safety Codes for Elevators and Escalators,” Section 5.2 B. ICC /ANSI A117.1 C . N FPA 70 National Electrical Code D . N FPA 101 Life Safety Code 1.05 S ystem Description: A. T ravel: ________(25' max) B. S tops: ________(up to 6) C . Load Capacity: 1400 lb. D . S peed: 30 fpm 1.06 S ubmittals: Submit product data, including manufacturer’s specifications and submittal drawings. 1.07 Quality Assurance: A. Installer Qualifications: A company experienced in the assembly and erection of elevators of the type specified; trained and certified by the manufacturer. B. Manufacturer Qualifications: A company specializing in the manufacture of lifts for the disabled and LU/LA elevators. 1.08 W arranty: Unit shall have a two (2) year limited parts warranty. 1.09 M aintenance: A. M aintenance of the LU/LA elevator shall consist of regular cleaning and inspection at intervals not longer than every 6 months. B. Inspection: ASME A17.1 requires all LU/LA elevators to be inspected every 6 months. PART 2 — PROD UCTS 2.01 M anufacturer: ThyssenKrupp Access, formerly National-Wheel-O-Vator 2.02 C omponents: A. Car: 1. S ize 42”W x 54” D clear (others available). 2. E nclosure: Securely fastened to the car frame and platform. Shall be constructed of formed sheet steel panels with powder coated finish. Floorboard shall be constructed of 1 1/2" AC plywood with fire retardant coating. 3. C ar Entrances: Automatically operated, horizontally sliding steel doors with a full height safety screen. 4. C ar Doors: Shall be 3'0" x 6'8" with powder coated finish. 5. Handrail: Stainless steel handrail. 6. T elephone: Recessed phone box. 7. C ontrol Panel: Provide one momentary pressure illuminated button for each landing, keyed in car stop switch and alarm button. 8. V isual feedback indicating call for car and car’s next travel direction. 9. S tandard Color: Autumn White (optional colors available). 10. Audible Feedback: Provide audible signal indicating car arrival and direction of travel. 11. T actile Feedback: Provide tactile/ Braille characters on car, hall call push buttons and hoistway door jambs. 12. Interior Lighting: Provide with automatic operation. B. Hoistway Entrances: 1. P rovide each entrance with an automatically operating, horizontal sliding door in frame with primed finish. 2. Fire Rating: Hoistway doors and frame shall be UL certified for 1 1/2 hour fire rating. 3. D oors shall be provided with an interlock. C . D rive System: Roped hydraulic (1:2) with a two speed valve and a submerged motor. D . C able System: 1:2 system using (2) 3/8" - 7x19 aircraft cable. E . Guide Rail: Shall consist of two 8 lb tee rails. F. C ar Frame: Shall be equipped with nonmetallic faced roller guide wheels. G. Leveling device: Provide hall effect switch system to maintain car within 1/4" of the landing. H. C ontrol Systems: Selective collective microprocessor, UL listed. I . M otor (submerged): 5.0 HP, 1750-RPM 208/230 VAC, single phase, (three phase available). J. W iring: 1. Provide flexible traveling cable for electrical lights and controls in car. 2. All other electrical wiring shall be insulated, flame retardant, moisture proof and installed in conduit. K. S afety Devices: 1. S lack cable protection with stainless steel linkage. 2. T erminal stopping device. 3. O ver speed protection. 4. P latform toe guard at the car entrance. L. T wo battery emergency operation system, which powers a car light, emergency alarm system and allows car to descend to bottom terminal floor. PART 3 — EXEC UTION 3.01 I nstallation: A. All components shall be assembled an erected in strict compliance with manufacturer’s printed instructions. B. All wiring shall be in accordance with the wiring diagram furnished by the manufacturer. 3.02 Field Quality Control: A. S tatic/Running Load Test: Load rating and safety factors shall meet or exceed those specified in ASME A17.1. ThyssenKrupp Access 4001 E. 138th Street Grandview, MO 64030 Ph: 800-829-9760 Email: sales@tkaccess.com Website: www.tkaccess.com ©2010 ThyssenKrupp Access Standard Color for Car & Car Doors Note: Color may vary due to printing process. Custom colors available upon request. Hoistway door and frame are prime coated. ThyssenKrupp Access carries a full-line of accessibility products including stair lifts, wheelchair lifts, dumbwaiters and residential elevators. Autumn White 012010 IBS EVO L

Open the catalog to page 1

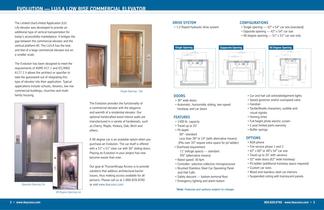

Opposite Opening Car 90 Degree Opening Car

Open the catalog to page 2Archived catalogs

-

H O M E E L E V A T O R S

6 Pages

-

VOLANT

4 Pages

-

evolution plan GD

8 Pages

-

RA 750 residential lift

2 Pages

-

Journey

2 Pages

-

Flow 2

5 Pages