Catalog excerpts

Thermafiber Mineral Wool Insulation Thermafiber Mineral Wool Insulation vs. Spray Polyurethane Foam Insulation in Pre-Cast Perimeter Fire Barrier Conditions Check it out for yourself... Spray Foam Insulation is not all its blown up to be! Factors to consider: · Combustibility · Toxicity · Environmental Impact and Sustainability · Ambient Temperature · Ease of installation · Durability · Cost effectiveness

Open the catalog to page 1

Thermafiber Mineral Wool vs. spray foam insulation (closed cell): Compare Thermafiber Mineral Wool to Spray Foam Insulation (Closed Cell). Compare the efficiency. Compare fire protection. Compare aesthetics. Compare prices, too. Whatever your criteria, the more you compare, the more benefits you'll find with Thermafiber. Thermafiber mineral wool insulation resists temperatures The flash point of Spray Polyurethane Foam (SPF) is approximately 392°F.2 Some SPFs can be treated with Fire Resistivity halogenated fire retardants, however, the additives only delay the time to flash and ultimately...

Open the catalog to page 2

Thermal Performance Characteristics Thermaber Mineral Wool Characteristic Thermaber mineral wool insulation has consistent R-values per thickness regardless of installation temperatures. R-values of mineral wool insulation are also not affected by aging. Although Thermaber products do have a lower R-value per inch versus aged R-values of SPF, this can be offset with increased thickness and still be more cost effective than foam insulation. R-Value Thermaber foil faced curtain wall insulation offers a permeability rating of 0.02 perms (grains/hr/ft2/in Hg) regardless of the thickness of...

Open the catalog to page 3

Installation Considerations (Continued) Thermaber Mineral Wool Characteristic Thermaber mineral wool insulation is manufactured in a preformed thickness, eliminating variable thickness problems and inconsistencies in R-value. Applied Thickness Spray Foam Insulation (Closed Cell) R-value is dependent upon the thickness of the insulation. SPF applications are difcult when trying to get a consistent thickness. Variable thickness and unevenness are common installation problems. Spray path thickness is critical and the manufacturer’s recommendations should be followed closely. There are multiple...

Open the catalog to page 4

Environmental Impacts Thermaber Mineral Wool Thermaber mineral wool insulation offers up to 90%recycled content. Standard mineral wool products offer a 70% recycled content. Thermaber mineral wool insulation contributes up to 33 credits across 4 categories. Thermaber mineral wool insulation contains no CFC or HCFC blowing agents. Thermaber follows the strict “Guides for the Use of Environmental Marketing Claims, commonly known as the “Green Guides”, per section 5 of the Federal Trade Commission Act. Characteristic Recycled Content LEED Green Building Credits Global Warming Potential Green...

Open the catalog to page 5

This graph demonstrates the Thermafiber Insolutions Insulation still intact, Test terminated without 1510°F Plate glass melts insulation melts 392°F Spray Foam Flash Point 300°F Rigid Foam Melts [1) Not for service operation at this temperature. Refer to the appropriate Thermafiber Insulation literature which states recommended maximum service temperature limits of Individual products. Time-temperature curve from "Standard of Methods of Fire Tests of Building Constructions and Materials." Email: info@thermafiber.com Thermafiber also supports all of its mineral wool products with Thermafiber...

Open the catalog to page 6All Thermafiber catalogs and technical brochures

-

FireSpan 90 & FireSpan 40

2 Pages

-

Thermafiber® SAFB?

2 Pages

-

Thermafiber® Safing?

2 Pages

-

Thermafiber® Spiral

2 Pages

-

Thermafiber® UltraBatt?

2 Pages

-

Filler / Reinforcement Fiber

2 Pages

-

Industrial Bulk Wool

2 Pages

-

Thermafiber® ThermaTex? 1800

2 Pages

-

Metal Mesh Blankets

2 Pages

-

High-Temperature Board

2 Pages

-

Semi-Refractory Felt

2 Pages

-

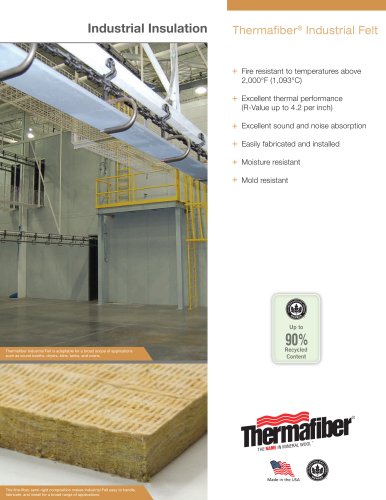

Thermafiber® Industrial Felt

2 Pages

-

thermafiber

2 Pages

-

FixtureShield

2 Pages

-

FS-15_FS-25

2 Pages

-

rainbarrier%20

2 Pages

-

/RainBarrier

2 Pages

-

Spiral

2 Pages

-

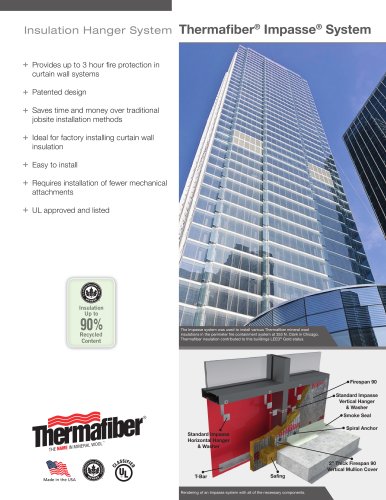

Impasse

2 Pages

-

VersaBoard

2 Pages

-

/SafingPaks

2 Pages

Archived catalogs

-

GREEN INSULATION

3 Pages

-

Thermafiber InsolutionsE

4 Pages

-

Thermafiber InsolutionsE

10 Pages

-

Thermafi ber® VersaBoard™

2 Pages

-

Thermafiber® TopStop®

2 Pages

-

Thermafi ber® SoundZero®

2 Pages

-

Thermafi ber® Safi ng™

2 Pages

-

Thermafi ber® SAFB™

2 Pages

-

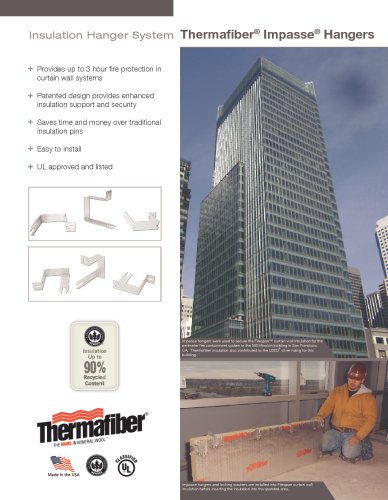

Thermafi ber® Impasse® Hangers

2 Pages

-

FireSpan 90 & FireSpan 40

2 Pages