Catalog excerpts

TensarTech® TW3 Smooth Earth Retaining System for Walls THE CHALLENGE TensarTech® TW3 Smooth has been developed to offer an alternative face finish to our current TW3 split face finish. TW3 Smooth now gives another option to specifiers and architects looking for a smooth concrete finish whilst still benefiting from reinforced soil technology. This is just one of several facing options engineers have when specifying TensarTech Earth Retaining Systems. INTRODUCING TENSARTECH® TW3 SMOOTH TensarTech® TW3 has been incorporated into many UK projects, from bridge abutments and highway retaining walls through to supermarket developments and housing schemes. TensarTech TW3 Smooth face has the same dimensions as current TW3 blocks and is available in a choice of colours. As with TW3 split face blocks, the TW3 Smooth builds to a near vertical face angle. THE ADVANTAGES OF TENSARTECH® TW3 SMOOTH • Smooth finish concrete blocks available in a choice of colours (standard colours are Flint and Yorkstone). • Rapid, economical construction. • Durable and maintenance free. • No specialist construction skills are required. • Proven, independently certified system. TENSARTECH® TW3 SMOOTH SYSTEM INFORMATION The System comprises of TensarTech® TW3 Smooth facing blocks, Tensar uniaxial geogrids, Tensar polymer connectors can when requested include an indemnified design that includes construction drawings and construction advice on-site via our UK civil engineering team. Although Tensar does not offer installation services we can supply a list of installers who work countrywide on Tensar projects. Near vertical attractive hard faced finish.

Open the catalog to page 1

TENSARTECH® TW3 SMOOTH TECHNICAL DATA • Delivery - Facing blocks are delivered palletised on self off-loading equipment. TensarTech® TW3 Smooth was chosen as an economic retaining solution, installed on a tight access site. A total of 120m2 was installed with a maximum retained height of 3.5m over a linear length of 75m. TensarTech TW3 Smooth was chosen due to minimal foundations and the advantages of a dry laid system with no mortar required, which meant there was no curing time or problems with wet weather working. The wall was backfilled using standard construction plant and locally...

Open the catalog to page 2All Tensar International catalogs and technical brochures

-

Tensar HX

1 Pages

-

Road-Technology

12 Pages

-

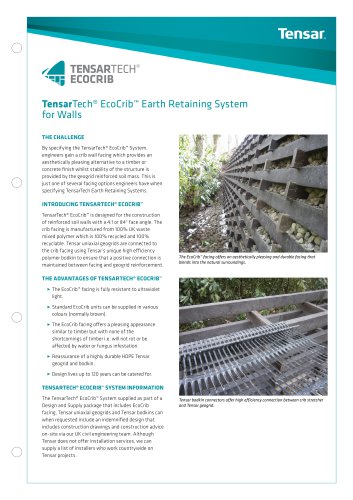

TensarTech® EcoCrib™

2 Pages

-

TensarTech® SlopeLoc™

2 Pages

-

TensarTech™ slopeloc™

3 Pages

-

Asphalt Reinforcement

10 Pages

-

Tensar_Erosion_Control

12 Pages

-

Tensar Mining Brochure

8 Pages

-

Tensar General Brochure

20 Pages

-

Tensar Architects Brochure

11 Pages

-

TensarTech Plateau Brochure

6 Pages

-

Tensartech TW1 Wall Brochure

6 Pages

-

TensarTech Stratum Brochure

6 Pages

-

TensarTech Ares

2 Pages

-

Tensar Ballast Stabilisation

2 Pages

-

Tensar Wind Energy Brochure

6 Pages

-

Tensar Erosion Control Brochure

12 Pages

-

Tensar GlasstexPatch 880

2 Pages

-

Tensar Mining Brochure

4 Pages

-

Tensar Railway Brochure

12 Pages

-

Tensar Sub ballast Stabilisation

12 Pages

-

Tensar TriAx Geogrid Brochure

12 Pages

-

TensarTech Stratum

6 Pages

-

Tensar Railways

12 Pages

-

Tensar Oil and Gas Brochure

5 Pages

-

TENSAR GEOPIER FOUNDATIONS

8 Pages

-

Tensar Erosion Control

12 Pages

-

Tensar_TriAx_TX

12 Pages

-

Foundations over Piles

6 Pages

-

Basal Reinforcement

6 Pages

-

TensarTech_TW3

6 Pages

-

TensarTech_TW1

6 Pages

-

Tensartech_TR2_System

4 Pages

-

TensarTech_NaturalGreen

6 Pages

-

TensarTech_GreenSlope

6 Pages

-

Tensartech_Geocell_brochure

6 Pages

-

Wind_Energy_Brochure

6 Pages

-

Tensar_Oil_and_gas_brochure

5 Pages

-

Tensar_GlasstexPatch_880

2 Pages

Archived catalogs

-

Tensar_Mining_Brochure

5 Pages

-

Tensartech_TW3

6 Pages

-

Tensar_Sales_Leafle

3 Pages

-

New_Architects

11 Pages

-

Tensartech_Green Slope

6 Pages

-

Tensar Uniaxial Brochure

16 Pages

-

Tensar Basal Reinforcement

8 Pages

-

Tensar Erosion Brochure

2 Pages

-

TriAx brochure 2010

12 Pages

-

Tensar Railways Brochure

12 Pages

-

Tensar General Brochure

20 Pages