Catalog excerpts

SUBGRADE STABILISATION mechanically stabilised layers for roads and trafficked areas

Open the catalog to page 1

Tensar ® TriAx® Geogrids have proven to be extremely efficient at confining and stabilising aggregate. TriAx has replaced Tensar biaxial geogrids in most stabilisation applications, delivering even greater cost savings. The Six Major Subgrade Stabilisation Applications for Tensar Technology Reducing Layer Thickness Increasing life Tensar Technology — Proven Practical Solutions and the Know-How to Build Them Based on the characteristic properties of Tensar geogrids, Tensar Technology is widely adopted for ground stabilisation and soil reinforcement problems, delivering real savings in cost...

Open the catalog to page 2

INCREASING CONTROLLING CAPPING BEARING DIFFERENTIAL WEAK SPANNING CAPACITY SETTLEMENT DEPOSITS VOIDS By applying Tensar Technology, the load spreading capability of a Tensar® TriAx® mechanically stabilised layer can increase the bearing capacity of working platforms for heavy-duty plant, cranes and piling rigs. Multiple layers of Tensar TriAx geogrids in an aggregate layer create a flexurally stiff platform. Through the use of Tensar Technology the effects of a variable quality of support from a foundation soil can be smoothed out. Where the ground is exceptionally...

Open the catalog to page 3

Tensar ® TriAx® Geogrids Work by Confining Aggregate Particles Tensar® TriAx® geogrids can solve stabilisation problems because they interlock very efficiently with granular materials. When granular particles are compacted over these geogrids, they partially penetrate and project through the apertures and abut against the ribs. Interlock is the mechanism by which the geogrid and aggregate interact under an applied load. This mechanism results in confinement and lateral restraint of the granular particles. The Interlock Mechanism Unconfined zone Transition zone (Partial confinement) Fully...

Open the catalog to page 4

Do All Geogrids Work in the Same Way? This is a common question when considering the benefits of using geogrids — particularly in a road pavement. The answer is, ‘No, geogrids perform differently and a good indicator of the reinforcing effect is the method of manufacture.’ The quality of the mechanical interlock is not the same when comparing the Tensar® manufacturing process with other methods of forming geogrids such as extruding, weaving and welding. Tensar designs are based on the proven mechanism of interlock and the lateral confinement of the aggregate. Most geogrids produced by other...

Open the catalog to page 5

Granular layers stabilised with Tensar® TriAx® geogrids perform as a composite due to the interlock mechanism. The geogrid/aggregate composite can then be regarded as a Tensar® Mechanically Stabilised Layer (MSL). Designers and specifiers can choose to specify a Tensar Mechanically Stabilised Layer and be confident in the knowledge that the properties and performance of the composite are known and definable. The ‘equivalent non-stabilised layer' can be thought of in different ways and therefore it can be introduced into existing design methods according to how the concept would fit best....

Open the catalog to page 6

1992 — Laboratory testing is repeatedly confirmed by on-site trials 1996 — The lateral confinement function of Tensar geogrids leads to significant reductions in rut depth 2000 — Full-scale laboratory tests at the UK Transport Research Laboratory comparing Tensar geogrid with alternative forms of geogrid These pictures display the types of research in which Tensar® International has been involved over the years. The data in these tests have provided the factors to employ in empirical design methods. Now the trend in pavement design is moving towards more analytical design methods where the...

Open the catalog to page 7

Each of the Six Major Applications Brings Major Benefits and These Can Often be Converted to a Cost Advantage Reducing layer thickness By reducing the capping layer thickness by up to 50% with no performance loss compared with a standard non-stabilised design, the contractor can save significant money on the costs of the ground improvement work as well as achieving savings of up to 50% in construction CO2 emissions. Increasing life Road rehabilitation, especially if it involves full depth reconstruction, is an expensive item for any road owner. A value engineering exercise can show that the...

Open the catalog to page 8

Practical Examples of the Major Applications • Reducing layer thickness • Increasing life • Controlling differential settlement TriAx installation, Stoke • Capping weak deposits • Increasing bearing capacity Stabilising weak soil in Ashbourne, Derbyshire • Reducing layer thickness • Increasing life Improving and strengthening the A66 in Melsonby • Reducing layer thickness • Increasing bearing capacity • Controlling differential settlement Stabilising ground to facilitate off-road parking

Open the catalog to page 9

Specialist Pavement Designs If heavy axles loading or highly concentrated wheel loads define the traffic loading, rather than repetitions of more moderate highway traffic, then specialist design methods for geogrids have been developed by Tensar® International. The granular layer may then require multi-layer geogrid stabilisation. Commonly used design methods for heavy-duty pavements have been adopted and modified to include the geogrid stabilisation benefits. typical heavy-duty pavement Heavy-duty pavements may require multi-layer geogrid stabilisation. Airport pavements As the weight of...

Open the catalog to page 10

Tensar® International Support Services Use Our Experience and Reliability for Unsurpassed Product Support PROFESSiONAL SOLUTiONS We offer the services of a team of professionals who can assist in developing concepts to support your design or undertake full construction design. We also provide advice and training on-site to assist you to effectively install our products and systems in your project. Our range of innovative products is combined with our global experience of thousands of projects in a wide variety of climatic conditions and soil types. This means that we provide you with a...

Open the catalog to page 11All Tensar International catalogs and technical brochures

-

Tensar HX

1 Pages

-

Road-Technology

12 Pages

-

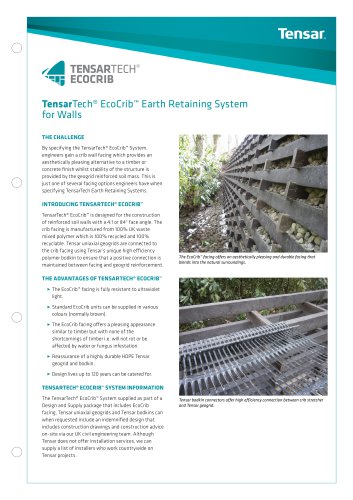

TensarTech® EcoCrib™

2 Pages

-

TensarTech® SlopeLoc™

2 Pages

-

TensarTech™ slopeloc™

3 Pages

-

Asphalt Reinforcement

10 Pages

-

Tensar_Erosion_Control

12 Pages

-

Tensar Mining Brochure

8 Pages

-

Tensar General Brochure

20 Pages

-

Tensar Architects Brochure

11 Pages

-

TensarTech Plateau Brochure

6 Pages

-

Tensartech TW1 Wall Brochure

6 Pages

-

TensarTech Stratum Brochure

6 Pages

-

TensarTech Ares

2 Pages

-

Tensar Ballast Stabilisation

2 Pages

-

Tensar Wind Energy Brochure

6 Pages

-

Tensar Erosion Control Brochure

12 Pages

-

Tensar GlasstexPatch 880

2 Pages

-

Tensar Mining Brochure

4 Pages

-

Tensar Railway Brochure

12 Pages

-

Tensar Sub ballast Stabilisation

12 Pages

-

Tensar TriAx Geogrid Brochure

12 Pages

-

TensarTech Stratum

6 Pages

-

Tensar Railways

12 Pages

-

Tensar Oil and Gas Brochure

5 Pages

-

TENSAR GEOPIER FOUNDATIONS

8 Pages

-

Tensar Erosion Control

12 Pages

-

Tensar_TriAx_TX

12 Pages

-

Foundations over Piles

6 Pages

-

Basal Reinforcement

6 Pages

-

TensarTech_TW3

6 Pages

-

TensarTech_TW1

6 Pages

-

Tensartech_TR2_System

4 Pages

-

TensarTech_NaturalGreen

6 Pages

-

TensarTech_GreenSlope

6 Pages

-

Tensartech_Geocell_brochure

6 Pages

-

Wind_Energy_Brochure

6 Pages

-

Tensar_Oil_and_gas_brochure

5 Pages

-

Tensar_GlasstexPatch_880

2 Pages

Archived catalogs

-

Tensar_Mining_Brochure

5 Pages

-

Tensartech_TW3

6 Pages

-

Tensar_Sales_Leafle

3 Pages

-

New_Architects

11 Pages

-

Tensartech_Green Slope

6 Pages

-

Tensar Uniaxial Brochure

16 Pages

-

Tensar Basal Reinforcement

8 Pages

-

Tensar Erosion Brochure

2 Pages

-

TriAx brochure 2010

12 Pages

-

Tensar Railways Brochure

12 Pages

-

Tensar General Brochure

20 Pages