Catalog excerpts

Railways Mechanical Stabilisation of Track Ballast and Sub-ballast

Open the catalog to page 1

2 Poor track geometry and a loss of vertical and horizontal alignment of the rails is a major reason for line speed restrictions and track maintenance work. These can significantly affect schedules and are expensive and disruptive to the public and the train operators. Track maintenance, involving ballast tamping or full ballast replacement, arises not only on weak subgrades but also on firmer supporting soils. Mechanical stabilisation of ballast, using Tensar geogrids, gives the railway engineer a rapid and safe solution. Tensar geogrids have been used to stabilise track ballast since the...

Open the catalog to page 2

When constructing track over soft subgrade having a low bearing capacity, it is necessary to improve the foundation to support the ballast effectively. This can involve a time consuming chemical stabilisation of the subgrade or deep excavation followed by importation and placement of a thick and expensive granular sub-ballast layer. Introducing Tensar geogrid reinforcement allows for a significant reduction of sub-ballast layer thickness for the same bearing capacity. This results in reduction of subgrade excavation and spoil disposal and much less imported sub-ballast fill, while still...

Open the catalog to page 3

For details of Tensar workshops visit www.tensar-international.com 4 Tensar geogrids make a structural contribution to railway trackbed. When granular fill material, such as ballast or sub-ballast, is compacted over a Tensar geogrid, it partially penetrates and projects through the apertures to create a strong and positive interlock. This interlock enables the geogrid to resist horizontal shear from the fill and restrains the granular material from lateral spread, which is a major cause of settlement of railway track. This mechanism is critical in helping to maintain the horizontal and...

Open the catalog to page 4

In 1986, full scale model laboratory tests were carried out to investigate the effect of Tensar geogrids in stabilising railway ballast and controlling the settlement of the sleeper. On both a weak and a firm subgrade, the geogrid reduced the rate of sleeper settlement such that the sleeper could sustain over 4 times the number of load cycles, across the practicable range of settlements. This indicated that there were great advantages to using geogrid stabilisation for all railway track in reducing settlement and reducing maintenance. Mechanical stabilisation of ballast to reduce...

Open the catalog to page 5

Installation of Tensar geogrids into the ballast over soft subgrade significantly reduces settlement, making it comparable with track on firm foundations (after Matharu, 1994*). In the early 1990’s British Rail Research investigated the use of a Tensar geogrid to limit the progressive lateral displacement of the ballast particles under repeated train loading. This investigated the settlement and the rate of deterioration of the vertical track geometry. The full scale trial using a 40 tonne rolling load rig to simulate 2 million gross tonnes on the track, consisted of three tests over a soft...

Open the catalog to page 6

7 Research at The University of Nottingham, UK 2006 Results from the Nottingham University Railway Test Facility (RTF) show that Tensar geogrids provide approximately 2.5 times increase in number of axle passes for same settlement (after Brown et al, 2006*). Number of cycles Over 2.5x Unreinforced Control Reinforced with Tensar geogrid 0 200,000 400,000 600,000 800,000 1,000,000 0 2 4 6 8 10 12 14 Settlement (mm) The Nottingham Rail Test Facility (RTF) allows a fullscale section of rail track, three sleepers in length, to be tested. Dynamic loading is provided by three hydraulic actuators...

Open the catalog to page 7

For details of Tensar workshops visit www.tensar-international.com 8 A demonstration project organised by Network Rail on the busy West Coast Main Line (WCML) between London and Scotland has confirmed the findings from the Nottingham laboratory research. An 800m section of track at Coppull Moor had a history of poor geometry and high maintenance. Network Rail decided to reconstruct this length of track with new ballast and sleepers. The demonstration was split into four sections; two control sections and two with Tensar geogrid ballast reinforcement. Network Rail has regularly monitored...

Open the catalog to page 8

9 Tensar geogrids have been used to stabilise ballast for almost 30 years and some monitoring of their condition, in the field, has been possible. At a site known as Shirland in the UK, the geogrid was installed in 1988 and in collaboration with the track operator Network Rail, geogrid samples were retrieved in 1997 and 2006. Since installation the railway had been trafficked by some 200 million gross tons of both freight and passenger trains. An assessment of abrasion was made by examining the tensile strength properties of a geogrid that was placed approximately 225mm below sleeper...

Open the catalog to page 9

Almost 30 years experience in mechanically stabilising granular fill Tensar International has developed the mechanical stabilisation of both sub-base and railway sub-ballast. A proven performance has been demonstrated in numerous trials, demonstrations and research projects. The resulting sub-ballast layer will provide significant savings in construction costs. The thickness and structural performance of sub-ballast, over weak subgrades, also ensures that the ballast layer has a sustained quality of support and maintenance needs can reduce significantly. The Bratislava to Trnava line in...

Open the catalog to page 10

11 Tensar soil reinforcement have Network Rail Product Acceptance Certification (Number PA05/175 & 177) for railway embankments, slope repairs and reinforced soil applications. *All technical references can be obtained from Tensar. 100 90 80 70 60 50 40 30 20 10 0 Unstabilised Stabilised 0 10 20 30 40 50 Subgrade modulus (Eu) Thickness h (mm) 1200 1000 800 600 400 200 0 Comparison of unreinforced and reinforced sub-ballast layers providing the same ballast support value (Eu) Unreinforced and reinforced designs ballast 1050mm sub-ballast 700mm sub-ballast E = 120 MPa Subgrade, Eu = 10 MPa...

Open the catalog to page 11All Tensar International catalogs and technical brochures

-

Tensar HX

1 Pages

-

Road-Technology

12 Pages

-

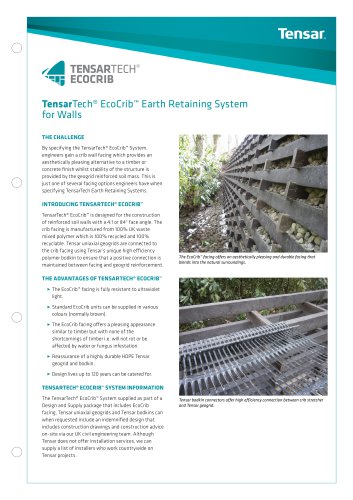

TensarTech® EcoCrib™

2 Pages

-

TensarTech® SlopeLoc™

2 Pages

-

TensarTech™ slopeloc™

3 Pages

-

Asphalt Reinforcement

10 Pages

-

Tensar_Erosion_Control

12 Pages

-

Tensar Mining Brochure

8 Pages

-

Tensar General Brochure

20 Pages

-

Tensar Architects Brochure

11 Pages

-

TensarTech Plateau Brochure

6 Pages

-

Tensartech TW1 Wall Brochure

6 Pages

-

TensarTech Stratum Brochure

6 Pages

-

TensarTech Ares

2 Pages

-

Tensar Ballast Stabilisation

2 Pages

-

Tensar Wind Energy Brochure

6 Pages

-

Tensar Erosion Control Brochure

12 Pages

-

Tensar GlasstexPatch 880

2 Pages

-

Tensar Mining Brochure

4 Pages

-

Tensar Railway Brochure

12 Pages

-

Tensar Sub ballast Stabilisation

12 Pages

-

Tensar TriAx Geogrid Brochure

12 Pages

-

TensarTech Stratum

6 Pages

-

Tensar Railways

12 Pages

-

Tensar Oil and Gas Brochure

5 Pages

-

TENSAR GEOPIER FOUNDATIONS

8 Pages

-

Tensar Erosion Control

12 Pages

-

Tensar_TriAx_TX

12 Pages

-

Foundations over Piles

6 Pages

-

Basal Reinforcement

6 Pages

-

TensarTech_TW3

6 Pages

-

TensarTech_TW1

6 Pages

-

Tensartech_TR2_System

4 Pages

-

TensarTech_NaturalGreen

6 Pages

-

TensarTech_GreenSlope

6 Pages

-

Tensartech_Geocell_brochure

6 Pages

-

Wind_Energy_Brochure

6 Pages

-

Tensar_Oil_and_gas_brochure

5 Pages

-

Tensar_GlasstexPatch_880

2 Pages

Archived catalogs

-

Tensar_Mining_Brochure

5 Pages

-

Tensartech_TW3

6 Pages

-

Tensar_Sales_Leafle

3 Pages

-

New_Architects

11 Pages

-

Tensartech_Green Slope

6 Pages

-

Tensar Uniaxial Brochure

16 Pages

-

Tensar Basal Reinforcement

8 Pages

-

Tensar Erosion Brochure

2 Pages

-

TriAx brochure 2010

12 Pages

-

Tensar General Brochure

20 Pages