Catalog excerpts

Contact Tensar International or your local distributor to receive further literature covering Tensar products and applications. Also available on request are product specifications, installation guides and specification notes. The complete range of Tensar literature consists of: • Tensar Geosynthetics in Civil Engineering A guide to products, systems and services • Ground Stabilisation Reinforcing unbound layers in roads and trafficked areas • TriAx™ A Revolution in Geogrid Technology The properties and performance advantages of Tensar TriAx™ geogrids • Asphalt Pavements Reinforcing asphalt layers in roads and trafficked areas • Tensartech Earth Retaining Systems Bridge abutments, retaining walls and steep slopes • Railways Mechanical stabilisation of track ballast and sub-ballast • Foundations over Piles Constructing over weak ground without settlement • Basal Reinforcement Using Basetex high strength geotextiles • Tensartech Geocell Mattress System • Erosion Controlling erosion on soil and rock slopes Your local distributor is: Tensar International Limited Cunningham Court Shadsworth Business Park Blackburn BB1 2QX United Kingdom ©Copyright Tensar International Limited Printed April 2011 Issue 1, SDA: 594970 The information in this brochure is supplied by Tensar International free of charge. Tensar International do not assume any duty of care to you or any third party. No liability for negligence (other than for death and personal injury) can arise from any use of or reliance on the information in this brochure or use of any Tensar International product mentioned. Tensar International will not be liable if this brochure contains any misrepresentation or misstatement. Determination of the suitability for any project of the information and any Tensar International product mentioned in it must be made by your engineer or other professional advisor who has full knowledge of the project. You, together with any such engineer or advisor, must assume all risk of loss and damage of any kind arising from use of the information or any product of Tensar International other than the risk of death and personal injury. If you or any third party subsequently purchases a product referred to in this brochure or any other Tensar International product the entire terms of the contract of purchase and the entire obligation of Tensar International relating to the product or arising from its use shall be as set out in Tensar International's Standard Conditions in force at the time of purchase, a copy of which may be requested from Tensar International. Tensar Technology for the Surface Mining Industry

Open the catalog to page 1

Saving money from a well designed haul road 2 Good haul road construction and subsequent maintenance practices are vital when operating a fleet of mining haulage trucks cost effectively. With truck haulage accounting for up to 50% of total surface mining costs, the savings to be gained from a well designed haul road using the appropriate materials are considerable. High performance stabilisation solutions of roads and working areas There are now unprecedented demands to design economic roads and working areas that reduce maintenance costs and improve haul truck efficiency. Tensar geogrids...

Open the catalog to page 2

Dump and head walls - high load resistant and durable Dump and head walls are vital to the operational efficiency of mines worldwide. It is vital that the walls are designed to be durable with the ability to carry the heavy loads and repeated traffic they endure. Tensartech Earth Retaining Systems enable structures to be built using locally won or recycled material, including colliery spoil. Benefits of Tensartech Earth Retaining Systems can include: ■ Rapid and economical construction ■ Durable with little or no maintenance ■ Resistance to impact loading ■ No specialist construction skill...

Open the catalog to page 3

Achieving safer working platforms Case study: Lee Moor Crushing Plant, Plymouth, UK In order to install a very large crushing and washing plant, Imerys Minerals PLC needed to construct a 17.7 metre high stepped structure. The fully loaded, 150 tonne delivery vehicles deliver their payload into the crushing plant that sits on the terrace. Surcharges from the vehicles and the “Big Grizzly” are extremely high (75kPa). The original design for the structure envisaged the use of a concrete panel to face the reinforced soil structure. The TR2 steel mesh panel system with its geotextile liner is...

Open the catalog to page 4All Tensar International catalogs and technical brochures

-

Tensar HX

1 Pages

-

Road-Technology

12 Pages

-

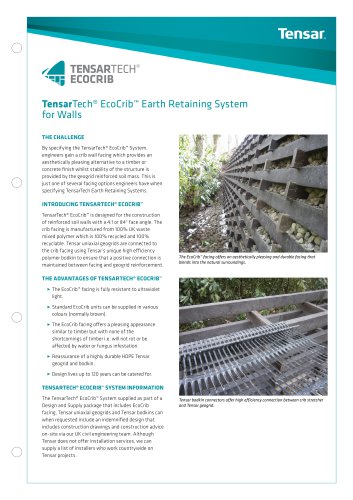

TensarTech® EcoCrib™

2 Pages

-

TensarTech® SlopeLoc™

2 Pages

-

TensarTech™ slopeloc™

3 Pages

-

Asphalt Reinforcement

10 Pages

-

Tensar_Erosion_Control

12 Pages

-

Tensar Mining Brochure

8 Pages

-

Tensar General Brochure

20 Pages

-

Tensar Architects Brochure

11 Pages

-

TensarTech Plateau Brochure

6 Pages

-

Tensartech TW1 Wall Brochure

6 Pages

-

TensarTech Stratum Brochure

6 Pages

-

TensarTech Ares

2 Pages

-

Tensar Ballast Stabilisation

2 Pages

-

Tensar Wind Energy Brochure

6 Pages

-

Tensar Erosion Control Brochure

12 Pages

-

Tensar GlasstexPatch 880

2 Pages

-

Tensar Railway Brochure

12 Pages

-

Tensar Sub ballast Stabilisation

12 Pages

-

Tensar TriAx Geogrid Brochure

12 Pages

-

TensarTech Stratum

6 Pages

-

Tensar Railways

12 Pages

-

Tensar Oil and Gas Brochure

5 Pages

-

TENSAR GEOPIER FOUNDATIONS

8 Pages

-

Tensar Erosion Control

12 Pages

-

Tensar_TriAx_TX

12 Pages

-

Foundations over Piles

6 Pages

-

Basal Reinforcement

6 Pages

-

TensarTech_TW3

6 Pages

-

TensarTech_TW1

6 Pages

-

Tensartech_TR2_System

4 Pages

-

TensarTech_NaturalGreen

6 Pages

-

TensarTech_GreenSlope

6 Pages

-

Tensartech_Geocell_brochure

6 Pages

-

Wind_Energy_Brochure

6 Pages

-

Tensar_Oil_and_gas_brochure

5 Pages

-

Tensar_GlasstexPatch_880

2 Pages

Archived catalogs

-

Tensar_Mining_Brochure

5 Pages

-

Tensartech_TW3

6 Pages

-

Tensar_Sales_Leafle

3 Pages

-

New_Architects

11 Pages

-

Tensartech_Green Slope

6 Pages

-

Tensar Uniaxial Brochure

16 Pages

-

Tensar Basal Reinforcement

8 Pages

-

Tensar Erosion Brochure

2 Pages

-

TriAx brochure 2010

12 Pages

-

Tensar Railways Brochure

12 Pages

-

Tensar General Brochure

20 Pages