Catalog excerpts

Tensar Glasstex®Patch™ 880 provides quick and easy localised maintenance repairs before paving operations. Use directly on existing pavements, nely milled surfaces, concrete substrates, for bridging cracks or to reinforce fractured asphalt. THE CHALLENGE Local and national highways engineers are constantly challenged with getting better value from tight budgets and reducing road maintenance costs. With a higher proportion of road maintenance budgets being spent on reactive repairs*, then there is a greater need for engineers to carry out maintenance repairs within budget and with minimised disruption to road users. INTRODUCING GLASSTEX®PATCH™ 880 Glasstex®Patch™ is a reinforcement composite specically developed for localised maintenance repairs between milling and paving operations. It can be used directly on existing pavements, nely milled surfaces, concrete substrates, for bridging open cracks or to reinforce fractured asphalt before the new overlay is installed. The composite is designed to inhibit the development of reective and fatigue cracks. Potholes and voids due to disintegration of the existing asphalt should be filled and open cracks should also be sealed before applying Glasstex®Patch™ 880. This product is also applicable to the construction of stable, durable asphalt sealing around iron works, where the combination of asphalt, concrete, mortar and iron causes reective and fatigue cracking. THE ADVANTAGES OF GLASSTEX®PATCH™ 880 Easy and fast installation No specialist installation required Glasstex®Patch™ 880 can be applied to most sound substrates utilising the adhesive coating. Easily transportable in roll sizes 15.0mL x 1.0mW Simple to cut to size on site for awkward areas e.g. around manholes and gullies Compatible with tack coat use on uneven substrates e.g. concrete or open texture asphalt Compatible with the new asphalt overlay through the quartz sand coating Reective cracking resistant through both stress relief and reinforcement eects No requirement for bitumen tankers or installation plant Provides reinforcement and waterproong of localised weak spots in a pavement such as service trenches Installed directly on a sound substrate using adhesive coating or heat activation Assists with bridging of joints between two pavement structures (i.e. bus lane and pavement) *Source: Annual Local Authority Road Maintenance (ALARM) Survey 2011, AIA

Open the catalog to page 1

GLASSTEX®PATCH™ 880 PRODUCT INFORMATION CASE STUDY: ALBERT ROYDS ROAD, ROCHDALE Glasstex®Patch™ 880 consists of a pre-coated glass yarn grid combined with a polymer modied bitumen membrane. The under side of the Glasstex®Patch™ 880 includes a self adhesive coating, while the upper side is treated with a quartz sand protective coating. The adhesive layer is protected during storage by a peel o release lm. Glasstex®Patch™ 880 provides a stress relief action by combining a dense polymer modied bitumen membrane with a coated and protected glass yarn grid asphalt reinforcement overlay. The...

Open the catalog to page 2All Tensar International catalogs and technical brochures

-

Tensar HX

1 Pages

-

Road-Technology

12 Pages

-

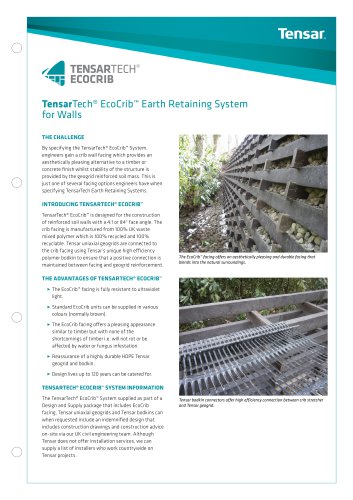

TensarTech® EcoCrib™

2 Pages

-

TensarTech® SlopeLoc™

2 Pages

-

TensarTech™ slopeloc™

3 Pages

-

Asphalt Reinforcement

10 Pages

-

Tensar_Erosion_Control

12 Pages

-

Tensar Mining Brochure

8 Pages

-

Tensar General Brochure

20 Pages

-

Tensar Architects Brochure

11 Pages

-

TensarTech Plateau Brochure

6 Pages

-

Tensartech TW1 Wall Brochure

6 Pages

-

TensarTech Stratum Brochure

6 Pages

-

TensarTech Ares

2 Pages

-

Tensar Ballast Stabilisation

2 Pages

-

Tensar Wind Energy Brochure

6 Pages

-

Tensar Erosion Control Brochure

12 Pages

-

Tensar GlasstexPatch 880

2 Pages

-

Tensar Mining Brochure

4 Pages

-

Tensar Railway Brochure

12 Pages

-

Tensar Sub ballast Stabilisation

12 Pages

-

Tensar TriAx Geogrid Brochure

12 Pages

-

TensarTech Stratum

6 Pages

-

Tensar Railways

12 Pages

-

Tensar Oil and Gas Brochure

5 Pages

-

TENSAR GEOPIER FOUNDATIONS

8 Pages

-

Tensar Erosion Control

12 Pages

-

Tensar_TriAx_TX

12 Pages

-

Foundations over Piles

6 Pages

-

Basal Reinforcement

6 Pages

-

TensarTech_TW3

6 Pages

-

TensarTech_TW1

6 Pages

-

Tensartech_TR2_System

4 Pages

-

TensarTech_NaturalGreen

6 Pages

-

TensarTech_GreenSlope

6 Pages

-

Tensartech_Geocell_brochure

6 Pages

-

Wind_Energy_Brochure

6 Pages

-

Tensar_Oil_and_gas_brochure

5 Pages

-

Tensar_GlasstexPatch_880

2 Pages

Archived catalogs

-

Tensar_Mining_Brochure

5 Pages

-

Tensartech_TW3

6 Pages

-

Tensar_Sales_Leafle

3 Pages

-

New_Architects

11 Pages

-

Tensartech_Green Slope

6 Pages

-

Tensar Uniaxial Brochure

16 Pages

-

Tensar Basal Reinforcement

8 Pages

-

Tensar Erosion Brochure

2 Pages

-

TriAx brochure 2010

12 Pages

-

Tensar Railways Brochure

12 Pages

-

Tensar General Brochure

20 Pages