Catalog excerpts

SAVING TIME, MONEY AND CARBON ON ROAD PROJECTS GLOBALLY KEEPING YOU UP-TO-DATE WITH ALL THE LATEST NEWS Why Britain's roads need Joined-Up Thinking ALSO INSIDE: STABLE FOOTING Estimated £2m saving on the A556 project A21 trunk road project Read the case study on page 04 Read the case study on page 11

Open the catalog to page 1

Collaboration is key to Joined-Up Thinking Tensar’s recent successes on the UK’s roads are not only down to the application of clever technical solutions but also the collaboration between infrastructure owners, designers, contractors, specialist sub-contractors and supplier. This Joined-Up Thinking delivers pavement and structural designs that save significant costs, accelerate construction and extend the operating life of assets, minimising maintenance and whole life costs and reducing disruption on the country’s busy roads, to keep the economy moving. Welcome to Tensar Road Technology In...

Open the catalog to page 2

WORKING WITH WHAT’S IN FRONT OF YOU Removing barriers to adopting innovation, and ensuring standards keep pace with technical developments, is essential if we are to meet future highways infrastructure needs. £27bn n March 2020, just before the coronavirus pandemic, the UK government announced a £27bn road building programme over the next five years, with spending on upgrading the existing network, as well as construction of new routes. While it is unclear how much of an impact COVID-19 will have on future spending, the UK is not alone in continuing to invest in its road networks. However,...

Open the catalog to page 3

Click here to download the full case study Stable footing Using geogrid to mechanically stabilise founding aggregate layers saved an estimated £2m on the A556 improvement scheme in Cheshire. n estimated 51,000 vehicles, including about 5,000 lorries, use the A556 between the M6 and the M56 every day. The route, linking south Manchester with commuter towns, including Altrincham, and Manchester Airport, has multiple junctions with local roads and is often congested, with a high number of serious accidents in the past few years. Highways England’s A556 Knutsford to Bowden Improvement Scheme...

Open the catalog to page 4

CASE STUDY Estimated project cost savings Using TriAx saved an estimated £2m in project costs, compared with dig and replace. This also meant a potential 10,000 lorry movements were avoided. Once the new road was opened, the original A556 was narrowed to a single carriageway and improved provision made for pedestrians, cyclists and horse riders, as part of a 'de-trunking' project. In numbers: Road length Tensar TriAx the clear winner Length of road supported by Tensar TriAx The Tensar mechanically stabilised layer exceeded the requirements for Foundation Class 1 by around 30%, improving the...

Open the catalog to page 5

A different way of thinking Chemical stabilisation is not the only cost-effective alternative to ‘dig and replace’ for delivering a robust and long-lasting roads network, says Tensar Senior Product Manager Jonathan Cook. wo of the central pillars of the UK Government’s Road Investment Strategy are to reduce maintenance costs by 30-50% and to reduce the environmental impact of roads, including their construction. There are a number of different – and greener - approaches to increase bearing capacity, that are faster and more cost-effective than traditional ‘dig and replace’, including...

Open the catalog to page 6

Tensar TriAx performs strongly in full-scale trafficking trials Research by the US Corps of Engineers has shown aggregate layers stabilised with Tensar TriAx deliver significant performance benefits to flexible road pavements, reducing surface rutting by up to 44%, compared with non-stabilised aggregate. esearchers confirmed that “incorporation of a multi-axial geogrid in a flexible pavement base course provides a significant structural benefit.” Results also demonstrated that incorporating Tensar TriAx geogrids could cut construction time and costs by up to 19% and reduce carbon emissions...

Open the catalog to page 7

Best performance Standard bitumen tack coats have delivered the best performance in geogrid-reinforced asphalt tests. ensar geogrid-reinforced asphalt systems installed with standard bitumen tack coats outperformed those using higher spray rates, as well as those using polymer-modified bitumen bond coats, in independent laboratory tests. “Results show using a 1.1l/m2 of tack coat with asphalt geogrid reinforcement is more effective than using a 2l/m2 spray rate and more effective than a polymer-modified bitumen bond coat, which could, in fact, affect performance, as well as being more...

Open the catalog to page 8

Click here to download the full case study CASE STUDY Smart solution A Stress Absorbing Membrane Interlayer delivered stronger, safer and more reliable running lanes for the M3 smart motorway project in Surrey. ore than 130,000 vehicles use the M3 between Junctions 2 (Thorpe and the M25) and 4a (Farnborough) every day. As part of Highways England’s smart motorways programme, the capacity of this congested three lane section has been increased, with hard shoulders converted to an additional running lane. The aim was to relieve congestion, smooth traffic flow and to improve journey...

Open the catalog to page 9

Structural solutions Load-bearing reinforced soil walls can cut construction costs by up to 75% and halve build times compared with traditional solutions, while being robust and low-maintenance, says Tensar's Senior Product & Application Technology Manager Craig Roberts. einforced (or mechanically-stabilised) soil is becoming a standard way of forming cost-effective walls and bridge abutments on highways, instead of the more traditional options that frequently involve piling and reinforced concrete. The approach uses layers of geogrid to reinforce soil, increasing bearing capacity and...

Open the catalog to page 10

Click here to download the full case study CASE STUDY Loads of support The TensarTech TW3 modular block reinforced soil system was the ideal solution for building the load bearing bridge abutments and wing walls for overbridges at two new grade separated junctions between Tonbridge and Pembury on the A21 in Kent. ensar worked with WSP to design the retaining structures for main contractor Balfour Beatty. The abutments were built using Department of Transport Type 6I/J aggregate, designed to meet bank seat loads of up to 566kN/m and to resist horizontal loads of up to 54kN. TW3 was used to...

Open the catalog to page 11All Tensar International catalogs and technical brochures

-

Tensar HX

1 Pages

-

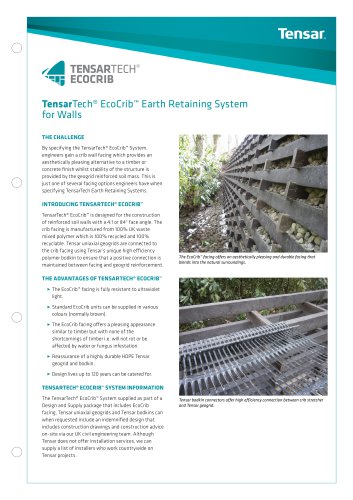

TensarTech® EcoCrib™

2 Pages

-

TensarTech® SlopeLoc™

2 Pages

-

TensarTech™ slopeloc™

3 Pages

-

Asphalt Reinforcement

10 Pages

-

Tensar_Erosion_Control

12 Pages

-

Tensar Mining Brochure

8 Pages

-

Tensar General Brochure

20 Pages

-

Tensar Architects Brochure

11 Pages

-

TensarTech Plateau Brochure

6 Pages

-

Tensartech TW1 Wall Brochure

6 Pages

-

TensarTech Stratum Brochure

6 Pages

-

TensarTech Ares

2 Pages

-

Tensar Ballast Stabilisation

2 Pages

-

Tensar Wind Energy Brochure

6 Pages

-

Tensar Erosion Control Brochure

12 Pages

-

Tensar GlasstexPatch 880

2 Pages

-

Tensar Mining Brochure

4 Pages

-

Tensar Railway Brochure

12 Pages

-

Tensar Sub ballast Stabilisation

12 Pages

-

Tensar TriAx Geogrid Brochure

12 Pages

-

TensarTech Stratum

6 Pages

-

Tensar Railways

12 Pages

-

Tensar Oil and Gas Brochure

5 Pages

-

TENSAR GEOPIER FOUNDATIONS

8 Pages

-

Tensar Erosion Control

12 Pages

-

Tensar_TriAx_TX

12 Pages

-

Foundations over Piles

6 Pages

-

Basal Reinforcement

6 Pages

-

TensarTech_TW3

6 Pages

-

TensarTech_TW1

6 Pages

-

Tensartech_TR2_System

4 Pages

-

TensarTech_NaturalGreen

6 Pages

-

TensarTech_GreenSlope

6 Pages

-

Tensartech_Geocell_brochure

6 Pages

-

Wind_Energy_Brochure

6 Pages

-

Tensar_Oil_and_gas_brochure

5 Pages

-

Tensar_GlasstexPatch_880

2 Pages

Archived catalogs

-

Tensar_Mining_Brochure

5 Pages

-

Tensartech_TW3

6 Pages

-

Tensar_Sales_Leafle

3 Pages

-

New_Architects

11 Pages

-

Tensartech_Green Slope

6 Pages

-

Tensar Uniaxial Brochure

16 Pages

-

Tensar Basal Reinforcement

8 Pages

-

Tensar Erosion Brochure

2 Pages

-

TriAx brochure 2010

12 Pages

-

Tensar Railways Brochure

12 Pages

-

Tensar General Brochure

20 Pages