Catalog excerpts

Three new settlement tanks were supported by driven precast piles, installed through very weak clays and founded in the underlying chalk bedrock. Reaping the benefits Analysis of the full benefits of stabilising geogrid in aggregate, using Tensar’s T-Value Method, meant a large working platform could be 350mm thinner, reducing construction time, costs and environmental impact. CLIENT’S CHALLENGE A 6,000m2 temporary piling platform over very weak ground was needed to build three settlement tanks at Beverley Sewage Treatment Works. The original design called for a 1.25m thick platform incorporating a reinforcement geogrid, requiring large volumes of imported aggregate and excavation and removal of existing soils. TENSAR SOLUTION Tensar used its T-Value Method to analyse the full benefits of the stabilising geogrid, rather than a reinforcement solution. This showed that a 350mm thinner platform could be built, with no impact on bearing capacity and load transfer efficiency. This helped cut construction time and costs by nearly a third, and reduced the platform’s carbon footprint by 40%. Beverley Sewage Treatment Works Temporary working platform Beverley, UK BENEFITS thinner working platform cut in construction time and costs reduction in the platform’s carbon footprint

Open the catalog to page 1

The exisiting ground was exceptionally low strength as shown from the onsite photos. PROJECT BACKGROUND The Beverley Sewage Treatment Works has been in operation since 1893. In 2017, Yorkshire Water announced a £25m project to completely rebuild and modernise the works, bringing them into the 21st century. Plans included construction of three new Final Settlement Tanks. Ground conditions on site were challenging, with Made Ground and thick deposits of very weak clay and organic material, with undrained shear strengths ranging from less than 5KPa to 10KPa. This meant the 20m diameter tanks...

Open the catalog to page 2All Tensar International catalogs and technical brochures

-

Tensar HX

1 Pages

-

Road-Technology

12 Pages

-

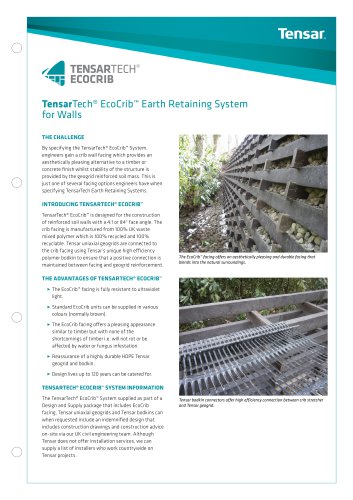

TensarTech® EcoCrib™

2 Pages

-

TensarTech® SlopeLoc™

2 Pages

-

TensarTech™ slopeloc™

3 Pages

-

Asphalt Reinforcement

10 Pages

-

Tensar_Erosion_Control

12 Pages

-

Tensar Mining Brochure

8 Pages

-

Tensar General Brochure

20 Pages

-

Tensar Architects Brochure

11 Pages

-

TensarTech Plateau Brochure

6 Pages

-

Tensartech TW1 Wall Brochure

6 Pages

-

TensarTech Stratum Brochure

6 Pages

-

TensarTech Ares

2 Pages

-

Tensar Ballast Stabilisation

2 Pages

-

Tensar Wind Energy Brochure

6 Pages

-

Tensar Erosion Control Brochure

12 Pages

-

Tensar GlasstexPatch 880

2 Pages

-

Tensar Mining Brochure

4 Pages

-

Tensar Railway Brochure

12 Pages

-

Tensar Sub ballast Stabilisation

12 Pages

-

Tensar TriAx Geogrid Brochure

12 Pages

-

TensarTech Stratum

6 Pages

-

Tensar Railways

12 Pages

-

Tensar Oil and Gas Brochure

5 Pages

-

TENSAR GEOPIER FOUNDATIONS

8 Pages

-

Tensar Erosion Control

12 Pages

-

Tensar_TriAx_TX

12 Pages

-

Foundations over Piles

6 Pages

-

Basal Reinforcement

6 Pages

-

TensarTech_TW3

6 Pages

-

TensarTech_TW1

6 Pages

-

Tensartech_TR2_System

4 Pages

-

TensarTech_NaturalGreen

6 Pages

-

TensarTech_GreenSlope

6 Pages

-

Tensartech_Geocell_brochure

6 Pages

-

Wind_Energy_Brochure

6 Pages

-

Tensar_Oil_and_gas_brochure

5 Pages

-

Tensar_GlasstexPatch_880

2 Pages

Archived catalogs

-

Tensar_Mining_Brochure

5 Pages

-

Tensartech_TW3

6 Pages

-

Tensar_Sales_Leafle

3 Pages

-

New_Architects

11 Pages

-

Tensartech_Green Slope

6 Pages

-

Tensar Uniaxial Brochure

16 Pages

-

Tensar Basal Reinforcement

8 Pages

-

Tensar Erosion Brochure

2 Pages

-

TriAx brochure 2010

12 Pages

-

Tensar Railways Brochure

12 Pages

-

Tensar General Brochure

20 Pages