Catalog excerpts

TATA STEEL Hollow sections For structural and mechanical application

Open the catalog to page 1

Hollow sections The benefits WHY HOLLOW SECTIONS? Steel hollow sections are the most versatile and efficient form for construction and mechanical applications. Many of the strongest and most impressive structures in the world today would not have been possible without hollow sections. The tubular form is inherently strong and efficient. It gives buildings a better strengthto-weight ratio than those using comparable steel, concrete or timber products. In construction, this strength-to-weight ratio reduces material usage and allows for greater spans. This results in lightweight, airy...

Open the catalog to page 2

Hollow sections The right product THE RIGHT PRODUCT FOR EVERY APPLICATION Tata Steel is one of the world’s leading producers of welded steel tube. We have been producing hot finished and cold formed hollow sections for more than 50 years. We have helped many customers to achieve a specific aesthetic or performance using steel.

Open the catalog to page 4

The Ultimate Structural Hollow Section Celsius® 355 is a hot finished product offering you a wide range of benefits. Made exclusively from normalised, fine grain steel, Celsius® 355 is fully stress-relieved with uniform mechanical properties. This makes it ideal for demanding structural and mechanical applications - delivering reliable performance, even at lower temperatures. Where looks matter, tight corner profiles, consistent dimensions and superior surface finish are hallmarks of Celsius® 355. It is also easy to fabricate, weld and manipulate to save you processing time and cost. For...

Open the catalog to page 5

Hollow sections Sustainability The essential properties of steel make it a sustainable choice for a wide range of applications. Steel is strong, durable, versatile, reusable and, most importantly, it is 100 per cent recyclable. Benefits of using steel The steel industry provides a stable working environment for many workers compared to other employment sectors. Tata Steel recycles more than three million tonnes of steel scrap each year in the UK, saving CO2 emissions equivalent to those produced by almost a million households. Tata Steel has also reduced steel-making CO2 emissions by 50 per...

Open the catalog to page 6

Steel has a high strength-to-weight ratio, meaning that less material is required. This reduces cost and makes steel one of the cheapest construction options. Steel construction is quick which contributes to low labour costs and 100% quicker lead times on projects or work. The result of this is a faster return on investment. Steel is 100 per cent recyclable and retains its value and properties for life. The use of steel normally results in less disruption to the local community by way of noise pollution and vehicle movements. It also produces zero waste. Steel can also be easily demounted...

Open the catalog to page 7

Hollow sections Expertise at your disposal OUR EXPERTISE IS AT YOUR DISPOSAL Steel tube is a relatively easy and particularly versatile material to work with. All customers who need help and advice can, however, benefit from Tata Steel’s years of specialist experience, research and development. We offer a comprehensive support service through detailed technical literature, a technical hotline and access to our experts for consultation at any stage in the design and construction process. Our experienced Technical Advisory Team use their knowledge of hollow sections to advise at all stages of...

Open the catalog to page 8

Hollow sections Manufacturing MANUFACTURING Tata Steel is one of the world’s leading producers of welded steel tube. From a variety of wall thicknesses and steel grades, we manufacture one of the widest ranges of steel hollow sections available. Tata Steel benefits from being a fully integrated steelmaker. We manufacture our own steel coil and convert it into tube via a number of tube-forming and finishing processes. This allows full visibility of the entire steelmaking process, ensuring complete traceability throughout the manufacturing chain. For more than 50 years now, we have been...

Open the catalog to page 10

Cold Process Route

Open the catalog to page 11

For more than 50 years now, we have been recognised as the pioneers behind steel hollow section production, with the knowledge and expertise that no other organisation can match.

Open the catalog to page 13

While care has been taken to ensure that the information contained in this brochure is accurate, neither Tata Steel Europe Limited, nor its subsidiaries, accept responsibility or liability for errors or for information which is found to be misleading. Copyright 2013 Tata Steel Europe Limited Tata Steel PO Box 101 Weldon Road Corby Northants NN17 5UA United Kingdom T: +44 (0)1536 402121 F: +44 (0)1536 404111 marketing@tatasteel.com English Language TST01:500:UK:09/2013

Open the catalog to page 14All TATA STEEL catalogs and technical brochures

-

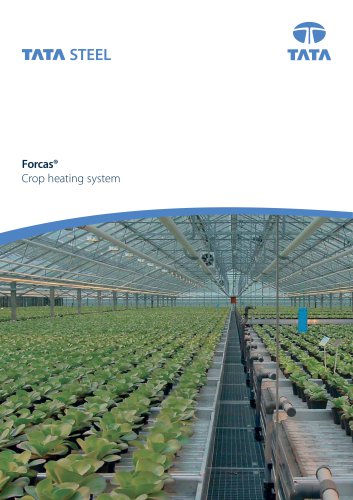

Forcas

8 Pages

-

Colorcoat®SDP 35

2 Pages

-

Colorcoat SDP 50

2 Pages

-

Colorcoat Aquatite

6 Pages

-

Colorcoat_Agriculture

16 Pages

-

Colorcoat Urban

12 Pages

-

Confidex® Home

1 Pages

-

Colorcoat GP

2 Pages

-

Colorcoat PVDF

2 Pages

-

Colorcoat PE 25

2 Pages

-

Colorcoat Prisma® colour card

11 Pages

-

Strongbox brochure

12 Pages

-

Hybox® 355

16 Pages

-

ComFlor manual

92 Pages

-

Colorcoat®SDP 35 - RWG

2 Pages

-

Colorcoat® PE 15

2 Pages

-

ColorcoatPrisma®

11 Pages

-

Trisomet®

48 Pages

-

Kalzip® FC rainscreen

24 Pages

-

Plates and Profiling Slabs

8 Pages

-

Trench_brochure_2010

8 Pages

-

Cold Formed Sections Brochure

36 Pages

-

Kalzip FC rainscreen system

20 Pages

-

Kalzip FC façade system

8 Pages

-

RoofDek

24 Pages

-

The surest way is steel

12 Pages