Catalog excerpts

Floor standing warm air generator (on demand pulleys with changeable diameter). The belt tension is easily obtained acting on the motor support slide. AISI 430 stainless steel COMBUSTION CHAMBER with flame inversion, with large heat exchange surface and low thermal loads. The fume exhaust is positioned opposite to the burner. BURNER GROUP: it is composed by a plate with a flame spyhole, insulated with a rigid ceramic fiber panel. The standard unit is supplied without burner. It is compatible with blown gas burners of any brand: when you send us the order we strongly recommend you to indicate which burner (brand and model) will be installed, in order to guarantee the supply of the correct burner plate; in case this information is missing we will supply the standard burner plate. HEAT EXCHANGER with aluminized steel modular elements, with swill impressions in order to obtain high thermal performances (up to 92,7%). Easy access for cleaning/maintenance. CONTROL AND SAFETY THERMOSTATS - Internal SUPPORTING STRUCTURE: it can be realized with a thick plate or with welded tubular (according to the model). All the standard units are supplied with the 2 suction vents (on 2 sides) and the upper delivery vent opened, without any grids/protections. VENTILATION GROUP made of 1, 2 or 3 (according to the model) double-suction centrifugal fans with aluminum fan and curved blades. Installed on flexible supports and dampers. Fans are statically and dynamically balanced. Large diameter fans (= High air flows and high static pressures) with low number of turns (= noiseless). “Safety” thermostat (manual reset, shuts down the burner when the internal temperature reaches 120°C) AIR SUCTION AND DELIVERY VENT (WITHOUT GRID/PROTECTION) Sandwich casing: internal galvanized plate + glass fiber + external white prepainted plate, modern and attractive, limited sizes, easy to be inspected. Bi-thermostat “Fan” + ”Limit” (“Fan” thermostat starts the fan when the internal temperature has reached 40°C; “Limit” thermostat shuts down the burner when the temperature exceeds 80°C) ATTENTION: it is forbidden to start the equipment if all the vents (suction and delivery) are not canalized or protected with grids or safety net available as accessories: standard grids, grids with air filter, closure panels, plenum, etc.) ELECTRICAL CONTROL PANEL Model: GHB 30 – GHB 40: 230V single phase motor directly coupled to the fan: 3 speeds equipped with thermal protection (Klixon), run capacitor permanently switched on, IP 42, B Class, electrical wires protected by a double insulation. Built in compliance with the international laws, 230V- 1 Ph- 50 Hz. Control panel with ON/OFF general switch; burner switch; fuses, remote control switch and relay for each fan motor. Optical signaling group with green lamp, which signs the electrical power supply presence. Model: GHB 60 – GHB 1000: 400 V three-phase motor and belt pulley, 1 speed, IP 55, F Class, electrical wires protected by a double insulation. Built in compliance with the international laws, 400V- 3Ph- 50Hz. Fan/motor transmission through fix diameter pulley and trapezoidal belts Motorizations (optional) 3 types of motorizations, according to the useful static pressures required by the installation: MSP - Medium head: for installations with standard ducts, that do not require special heads. HSP - High head: for installations with articulated distribution channels or with high air speed, that require special heads. Suitable for static pressure covers, tennis courts bearing covers (geodetic), gym, swimming pools and warehouses. SSP - Standard head: installations with plenum or short ducts. In these cases it is enough a low number of fan turns, assuring a higher acoustic comfort (low noise) and lower management costs (lower electrical

Open the catalog to page 1

Nominal thermal input Heating capacity output Thermal efficiency Air flow Static pressure Sound level Power supply Ventil/Module Sections Burner box Burner selection Nozzle length (Min-Max) Nozzle diameter Counter pressure combustion chamber The data on table are merely indicative according to the product’s updating. We kindly invite you to contact Systema’s technical department for further information.

Open the catalog to page 2All SYSTEMA S.P.A. catalogs and technical brochures

-

SCR-ELE

8 Pages

-

OHA 18-36

8 Pages

-

OHA URHE

8 Pages

-

DS

1 Pages

-

SV

2 Pages

-

EOLO BC-BL RT

4 Pages

-

GENERAL CATALOGUE

144 Pages

-

Fresco OK

4 Pages

-

KING

8 Pages

-

SCR

8 Pages

-

EOLO B RT

12 Pages

-

EOLO B

12 Pages

-

EOLO VIP

20 Pages

-

AIR BREEZE - AIRJET

8 Pages

-

F-LUX

8 Pages

-

Fresco

6 Pages

-

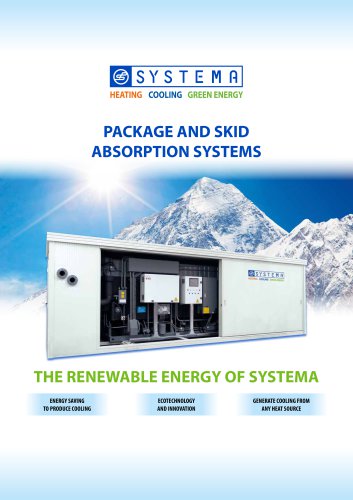

Renewable energy

2 Pages

-

INFRA DES

8 Pages

-

OHA

4 Pages