Catalog excerpts

Description: UltraFiber ® 500 reinforcement fiber for concrete is 100% virgin specialty cellulose fiber with a patented alkaline resistant coating specifically engineered and manufactured in an ISO 9001 certified facility. UltraFiber 500® provides secondary reinforcement in concrete (temperature and shrinkage crack control) and meets ICC evaluation criteria for use in slab on grade. UltraFiber 500® is manufactured in the USA from renewable resources and complies with National Building Codes, ASTM C1116-08 and ASTM D7357-07. A dosage rate of 1.0 to 4.0 lb/yd3 is recommended depending on the application. In areas where freeze/thaw performance is a significant factor, a 2.0 lb/cy dosage rate is strongly recommended with a 1.5 lb/cy dosage rate minimum Applications: • Commercial & Residential Slabs • Composite Metal Decks • Paving • Pervious Paving • Curb and Gutter • Slip Form • Architectural & Decorative • Pre-Cast • Shotcrete • Walls • White Topping Advantages: UltraFiber 500® provides excellent secondary reinforcement from high fiber surface area, close fiber spacing, excellent bonding within the cement matrix, high fiber tensile strength, and easy dispersion in concrete so it is always positioned correctly. It is safe, easy to use, and offers superior finish-ability. UltraFiber 500® provides significant benefits in numerous applications. Benefits: • Alternate system to traditional secondary reinforcement in concrete • Reduces the formation of intrinsic cracking in concrete • Reduces concrete permeability and absorption. • Improves concrete freeze/thaw resistance • Improves concrete durability • Provides enhanced hydration which improves concrete strength properties • Improves concrete impact resistance • Improves concrete shatter resistance • Improves bond strength between rebar and cement paste Concrete Fire Resistance: • UL Classified for use in all composite metal deck Designs No. D700, D800 & D900. • UL Classified for use in composite metal deck Design No. D973 Reduced Thickness of NWC (normal weight concrete) while achieving a 2 Hour Fire Rating Water Absorption Specific Gravity Avg. Fiber Length Projected Fiber Diameter Fiber Tensile Strength Alkali Resistance Up to 80% of the fiber weight 1.10 2.1 mm 18 um 90 -130 ksi High (ASTM D6942) For additional information please contact us at 800-624-0261 or visit www.ultrafiber500.com. This publication should not be construed as engineering recommendations or advice. Users of this product should determine its suitability for their own particular application. UltraFiber 500®is sold with no express or implied warranty; seller's sole liability for claims is limited to replacement of defective or

Open the catalog to page 1

UltraFiber® 500 UltraFiber Excellent Bond Count, fibers/lb. 720,000,000 Density, g/cm3 1.10 Usage Guideline UltraFiber 500® reinforcing fiber can be used as an alternate system to provide secondary reinforcement. It cannot be used as an alternative for structural reinforcement. UltraFiber 500® fiber should not be used to alter the concrete design for thickness or strength. ACI recommended curing practices, joint spacing and depth should be followed. Mixing Procedure UltraFiber 500® reinforcing fibers disperse best when added at the beginning of the batching sequence. Follow normal...

Open the catalog to page 2All Solomon Colors catalogs and technical brochures

-

DAY1 Catalog

12 Pages

-

Fiber Dispenser Gen 2

2 Pages

-

Accent~Colour Release™

1 Pages

-

Colour Hard™

2 Pages

-

BRICKFORM

21 Pages

-

PRODUCT GUIDE

17 Pages

-

Surface Deactivator

2 Pages

-

Solomon Concrete Colors

4 Pages

-

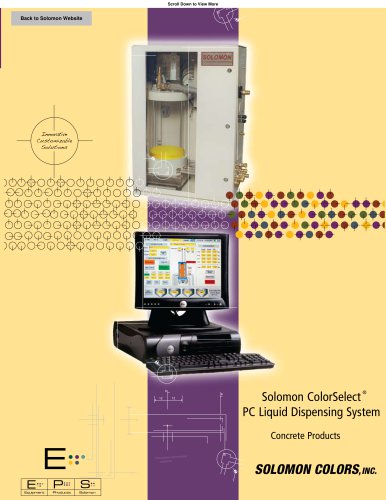

ColorSelect® Equipment

6 Pages

-

Mortar Color Sweets

4 Pages