Catalog excerpts

UltraFiber 500' Generation 2 Automated Dispenser FOR CONCRETE PRODUCTION APPLICATIONS IMPROVE PROFITABILITY, EFFICIENCY, AND SAFETY with the UltraFiber 500 Generation 2 Automated Dispenser. Fiber is an excellent value-added product for concrete, but it can often be difficult to dose. The UltraFiber 500 Gen2 Automated Dispenser removes the difficulty, guess work, and labor from incorporating fiber. The UltraFiber 500 Gen2 Automated Dispenser is as unique and innovative as UltraFiber 500 itself. The Generation 2 version of our UF500 Dispenser brings higher safety standards to the simple and highly successful 2001 original UF500 dispenser design. Gen 2 allows for top loading or front loading. The new version bin allows for lifts from the bottom of the sack to a 4' height, from above the sack or over the top of the bin. When frontloading, there is no need to empty the super sack as this design allows for gravity feed directly from the bottom of the bag. Whether front loading through the locking, weatherproof doors or using the included hanger rack to refill, your operators can refill the system safely and easily. New technology features, such as flow detection of the fiber and low-voltage wiring, also make the system easier to install and increases reliability and of operation. CONTROL The UltraFiber 500 Gen2 Automated Dispenser seamlessly integrates with most existing control systems. This means the batch manager can dose exact amounts of fiber without leaving the workstation. Batch tickets confirm fiber dosage. Requires computer slot module or optional timer box for automation. SOLOMON ADVANTAGE All UltraFiber 500 Gen2 Automated Dispensers are designed and built in the United States. Designated Solomon Colors service technicians are available nationwide and around the clock for troubleshooting, preventative maintenance, and repair to keep your system up and running. FLEXIBILITY An UltraFiber 500 Gen2 Automated Dispenser can be easily placed in most plants. The dispenser can be placed up to 120 feet from the discharge point and the flexible auger can bend around corners up to 60 degrees. Beyond that, the UltraFiber 500 Gen2 Automated Dispenser only requires a stable base, electrical hookups, and compressed air. SPEED & ACCURACY Manually gathering bags of fiber and carrying them to the mixer can take 5-10 minutes. Automation does this in less than 1 minute, and with accuracy. The UltraFiber 500 Gen2 Automated Dispenser has a high feed rate; it can dose as much as 10 cy of concrete in a minute. The high capacity storage silo holds enough fiber for over 1000 cy at a 1.5 lb/cy rate. High capacity supersacks and a convenient top-loading design make it easy to refill in a matter of minutes. SOLOMON COLORS, INC. CORPORATE HEADQUARTERS: 4050 Color Plant Road, Springfield, IL 62702 • (800) 624-0261 • www.solomoncolors.com

Open the catalog to page 1

UltraFiber 500 Generation 2 Automated Dispenser ® AUTOMATED ULTRAFIBER CABINET DISPENSER SPECIFICATIONS: • 1000 lb. capacity • Feed rate: Approx. 15 lbs./min. • Max auger length: Up to 100’ • Max auger angle: 60 degrees FOOTPRINT • Height: 108” • Length/width: 52”x52” REQUIREMENTS • Base: 5’x5’’ concrete pad for stability • Electricity: 110 V, 15 AMP • Compressed air • Electrician, man-lift and welder at installation (provided by customer) SOLOMON COLORS, INC. CORPORATE HEADQUARTERS: 4050 Color Plant Road, Springfield, IL 62702 •

Open the catalog to page 2All Solomon Colors catalogs and technical brochures

-

UltraFiber 500

2 Pages

-

DAY1 Catalog

12 Pages

-

Accent~Colour Release™

1 Pages

-

Colour Hard™

2 Pages

-

BRICKFORM

21 Pages

-

PRODUCT GUIDE

17 Pages

-

Surface Deactivator

2 Pages

-

Solomon Concrete Colors

4 Pages

-

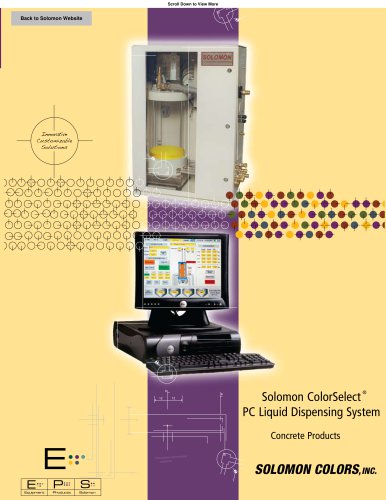

ColorSelect® Equipment

6 Pages

-

Mortar Color Sweets

4 Pages