Website:

SOLARFOCUS

Website:

SOLARFOCUS

Catalog excerpts

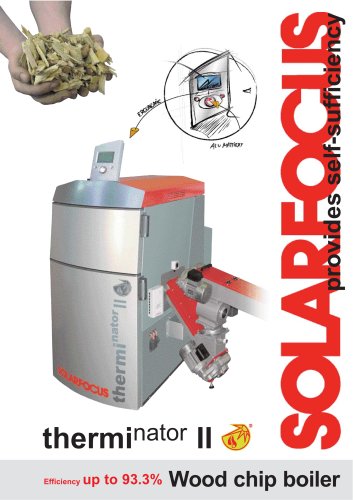

Efficiency up to 93.3% Wood chip boiler therminator II provides self-sufficiency

Open the catalog to page 1

Comforting - when the 2 25 years experience in the development of wood distilling boilers provides you with a perfectly proven product! Comforting Efficient up to: 93,3%

Open the catalog to page 2

3 fuel grows just outside the front door! SOLARFOCUS is shaping the future with products to serve mankind and conserve the environment! Wood chips are a by product of domestic forestry and forest management. This fact makes them into a favourable alternative to fossil fuels. Wood chips from the local area for the local community independence for generations Advantage Ideal for firewood too - can be upgraded for wood chips at any time!

Open the catalog to page 3

4 Heating with biomass is crisis-proof Wood is a domestic energy source, saves jobs and increases local value creation! The farmer as energy supplier Biomass - energy from “stored solar energy” In contrast to fossil fuels, wood as a combustible energy source releases almost no sulphur and is CO2-neutral. Heating as part of the natural cycle The CO2 released from burning wood is used to create new biomass. Hence the use of wood as an energy source is a worthwhile contribution to the ecological closed-loop economy. Wood - local energy The farmer as energy supplier. Every year, through...

Open the catalog to page 4

Technical details - to your advantage! The latest technology enables economic heating (1) The lambda sensor: As the first user of the lambda sensor in boiler construction (since 1981) SOLARFOCUS has continuously extended this lead in technology. Only through the patented, optimised placing of the lambda sensor are optimum combustion values and, above all else, a long sensor service life, achieved. (10) Funnel grate: The wood chips fall from above into the patented, funnel-shaped chromium steel cast grate. The required wood chip quantity is automatically optimised by the control (dependent...

Open the catalog to page 8

(15) Stainless steel charging chamber: The conically shaped, stainless-steel charging chamber, designed to accept 1/2 metre split logs (max. length 56 cm) also guarantees a long firing duration when operated with firewood. The charging chamber has a 10 year guarantee. (11) Large capacity ash chamber: In the therminator II special attention has been paid to the design of a particularly generously sized ash chamber, in order to achieve as long as possible intervals between emptying. The high temperature refractory plates are individually mounted in the combustion chamber (17) Fly ash box The...

Open the catalog to page 9

Agitator diameter dependent on storage room 2 m, 2.5 m, 3.0 m, 3.5 m and 4.0 m Open length must be matched 1.0 m, 1.5 m and 2.0 m to the storage room and agitator Screw length: 2 m to 6 m in 0.5 m steps 10 therminator II conveyor technology Agitator diameter Open length Screw length 170 mm Schematic representation 4 6 5 7 11 8 10 9 Legend: 1 Progressive leaf springs 2 Heavy duty gearbox 3 “Open” conveyor channel 4 Screw conveyor 5 “Closed” conveyor channel 6 Gearbox/motor for screw conveyor 7 Rotary feeder 8 Ball compensator 9 Sensor 10 Gearbox/motor for wood chip feed 11 Wood chip feed...

Open the catalog to page 10

11 2 1 3 low-noise robust “High technology conveying” low-noise - due to intelligent channel and conveyor technology YOUR benefits: only 230V power supply required minimal power consumption - 232 W/h

Open the catalog to page 11

12 YOUR benefits: The agitator diameter can be matched to therminator II conveyor technology Agitator The flat-steel agitator carries the wood chips to the room extraction screw conveyor. Progressive leaf springs guarantee efficient emptying of the wood chip storage room. The heavy duty gearbox, which was specially developed for wood chips has an output side braking load of over 27,000Nm. It is particularly sturdily built and dust-tight to ensure permanent trouble-free operation. The agitator diameter can be matched to the spatial requirements from 2 to 4 metres in 1/2 metre steps....

Open the catalog to page 12

13 the room requirements from 2 to 4 metres in 1/2 metre steps. Screw conveyor/drive unit The drive unit comprises a spur gear (480Nm) and drive motor (230V), which drives the conveyor screw, which is directly connected to the heavy-duty gearbox at the agitator. Roller link chain With the direct room extraction system, the rotary feeder is driven by a roller link chain from the drive unit. With downpipe extraction, the rotary feeder is driven by its own drive unit. The rotary feeder is one of the most important safety devices in the boiler. The 4-chamber system separates the wood chip feed...

Open the catalog to page 13

14 Charging and storage options Irrespective of application ... Direct room extraction system Charging with Front loader Tipper Rear shovel ... The angle compensator permits compensation of level differences between the boiler room and storage room. Direct room extraction system Charging with air injection pump convenient no rebuilding necessary nearly complete filling Direct room extraction system with conveyer screw for difficult to access cellar spaces

Open the catalog to page 14

15 ... we have the solution Downpipe room extraction Charging with blower if the storage room lies above the boiler room Downpipe room extraction Charging with Front loader Tipper Rear shovel ... Room extraction system with lifting screw to overcome height differences for bridging long distances max. 6 m long max. 21° angle

Open the catalog to page 15

16 therminator II control technology Simple operation - maximum comfort Innovative heating and boiler control ecomanager The control ecomanager: Full power display with background lighting Simple operation at the twist of a knob Clearly laid out display of plant system parameters (system values are graphically processed). Integral solar control Weather-controlled heating circuit control for 2 separate heating circuits (optionally expandable to 4 or 6 heating circuits) 32 bit processor Fully digital combustion control Updatable system (software can be updated over the telephone line)...

Open the catalog to page 16

Using the digital remote control module with integral room temperature sensor, it is possible to control the complete heating system including all heating circuits from the living space. Likewise, it is also possible to control every heating circuit individually via a digital remote control module. 17 Access to all important heating and system parameters, even from the living-room. Consumer 3 Consumer 2 Consumer 1 Maximum comfort and energy output ecomanager - perfect combination

Open the catalog to page 17All SOLARFOCUS catalogs and technical brochures

-

pelletelegance

12 Pages

-

Short Information: OCTOPLUS

2 Pages

-

Pellet Boiler OCTOPLUS

16 Pages

-

Combi boiler THERMINATOR II

16 Pages

-

Solartechnik CPC Kollektor

24 Pages

-

Pelletkessel PELLET TOP

20 Pages

Archived catalogs

-

Leaflet: DHW-Tank Plug-IN

2 Pages