Website:

Sika France SAS

Website:

Sika France SAS

Group: Sika

Catalog excerpts

SYSTEM DATA SHEET Sikafloor® MultiFlex PB-32 UV POLYURETHANE SLIP AND UV-RESISTANT TOUGH-ELASTIC FLOORING SYSTEM PRODUCT DESCRIPTION APPROVALS / STANDARDS Sikafloor® MultiFlex PB-32 UV is a polyurethane, slip and UV-resistant, tough-elastic flooring system. It provides a safe slip resistant surface in dry and wet conditions. ▪ CE Marking and Declaration of Performance to EN 1504-2 - Surface protection product for concrete Coating ▪ CE Marking and Declaration of Performance to EN 13813 - Resin screed material for internal use in buildings ▪ Fire testing EN 13501-1, Sikafloor®-3240, MPA Dresden, Report No. 20150909/01 USES Sikafloor® MultiFlex PB-32 UV may only be used by experienced professionals. Industrial slip resistant resin flooring on cementitious substrates for: ▪ Life Science production areas ▪ Automotive production plants ▪ Storage areas ▪ Logistic areas ▪ Multi-storey and underground car park decks and ramps Thickness ~3.0 mm. Good UV resistance Good mechanical resistance Good chemical resistance Scratch resistant surface Low dirt pick up Easy cleanability Seamless Slip and skid resistant surface i-Cure based technology wearing layer Low VOC content Low maintenance Application on asphalt surfaces System Data Sheet Sikafloor® MultiFlex PB-32 UV February

Open the catalog to page 1

SYSTEM INFORMATION System Structure Layer 1. Primer 2. Base coat Broadcast 3. Seal / Top Coat Product Sikafloor®-150/-151 Sikafloor®-3240 (filled 1:0.5 with quartz sand 0.06–0.3 mm) by weight Quartz Sand (0.3–0.8 mm) to excess Sikafloor®-359 N On substrates with hot poured/mastic asphalt, use Sikafloor®-3240 as a primer . These figures are theoretical and do not allow for any additional material due to surface porosity, surface profile, variations in level or wastage etc. Slip resistant, matt finish Seal /Top coat available in many colours. Refer to the Sikafloor®-359 Product Data Sheet...

Open the catalog to page 2

Beware of condensation. The substrate and uncured applied floor material must be at least +3 °C above dew point to reduce the risk of condensation or blooming on the surface of the applied product. Substrate Temperature Substrate Moisture Content ≤4 % parts by weight The following test methods can be used: Sika®-Tramex meter, CM - measurement or Oven-dry-method. No rising moisture according to ASTM (Polyethylene-sheet). Applied Product Ready for Use Foot traffic ~72 hours ~24 hours ~18 hours Light traffic ~6 days ~4 days ~2 days Full cure ~10 days ~7 days ~5 days Times are approximate and...

Open the catalog to page 3

Sheet for the exact description of the application fields. ECOLOGY, HEALTH AND SAFETY For information and advice on the safe handling, storage and disposal of chemical products, users shall refer to the most recent Safety Data Sheet (SDS) containing physical, ecological, toxicological and other safety-related data. LEGAL NOTES The information, and, in particular, the recommendations relating to the application and end-use of Sika products, are given in good faith based on Sika’s current knowledge and experience of the products when properly stored, handled and applied under normal...

Open the catalog to page 4All Sika France SAS catalogs and technical brochures

-

SikaForce®-335 GG

2 Pages

-

SikaMembran® Universal

2 Pages

-

Sikafloor® PurCem® HB-23

4 Pages

-

Sika Comfortfloor® PS-65

4 Pages

-

Sika Comfortfloor® PS-27

4 Pages

-

Sika Comfortfloor® PS-23

4 Pages

-

SikaCor® EG-5

4 Pages

-

Sikagard®-62

3 Pages

-

Sikasil® FS-665 SL

2 Pages

-

Sikasil®-670 Fire

3 Pages

-

Sikasil® WS-605 S

2 Pages

-

ADHESIVES AND WEATHER SEALING

28 Pages

-

Sika® PowerCure

2 Pages

-

references_sarnafil

8 Pages

-

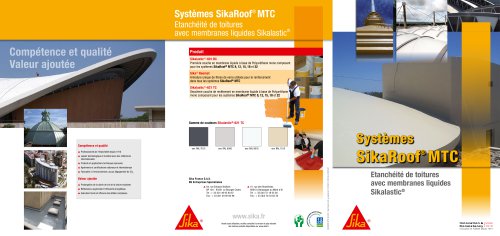

sikalastics

2 Pages

-

sarnafil

12 Pages