Catalog excerpts

Secco Sistemi is an Italian brand that symbolises innovation and design. It has been contributing to the evolution of the engineering of doors and windows for 70 years, inventing systems and profiles that have become benchmarks for the industry of this sector, and continuing to improve them and interpret the latest projects and trends of contemporary architecture. So far 280 profiles have been developed in 4 select metals - galvanised steel, stainless steel, corten steel and brass - and in 8 different finishes with an annual production of two million linear metres of profiled bars for...

Open the catalog to page 2

Secco Sistemi thermal break windows and doors tubular profile windows and doors pages with technical specifications designing with steel 5 integrated door and windows 7 building with steel 9

Open the catalog to page 3

designing with steel Of the highest quality, the metal alloys used by Secco Sistemi have precise characteristics: they are natural, created numerous innovative systems of metal profiles whole and safe, ductile and versatile. Furthermore, for doors and windows for use in the field of architecture, while appreciated for their structural resistance and thus contributing to the evolution to the engineering duration over time, necessitating little maintenance, of these architectonic elements, developing the design they are also recyclable and re-usable. natural, solid and precious, long-lasting....

Open the catalog to page 4

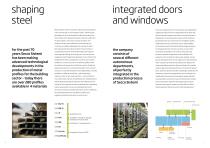

shaping steel integrated doors and windows Metal profiles were first used to make doors and windows in the second half of the nineteen-forties, following the regarding production of the single elements of which the development of the technique of folding or bending the door and window systems are made of, and constitute an sheet metal which allowed, however, only the production integral part of the production process of Secco Sistemi. of open profiles. It was ‘Secco Industrie’ back in the Each department is an expression of the highest quality, nineteen-fifties that realized the first...

Open the catalog to page 5

building with steel seccolab Secco Lab is the in-house laboratory of Secco Sistemi in which, by means of specific sophisticated equipment, international markets with tailor-made solutions for ideas and projects are tested, prototypes are conceived or top-level construction. This is possible thanks to a special solutions studied. The partnership with the German well-consolidated network of over 500 window & door institute IFT Rosenheim of testing and certification enables specialists, partners with vast experience and proven the company to carry out trials, tests and certification of Secco...

Open the catalog to page 6

choosing steel when the project favours natural materials, in the wide range of solutions, surfaces and manufacturing processes offered by Secco Sistemi, steel is the choice Many elements must be taken into consideration by the designer in the choice of material: coherence with the project as a whole and with the type of intervention to be realized, whether a new construction or renovation, the suitability of the material to the structural system and its function, place and collocation in a particular context. Choosing natural and precious materials such as galvanised steel, stainless...

Open the catalog to page 8

• galvanised steel • painted galvanised steel the important features of galvanised steel are the elasticity modulus or E-modulus, which is three times superior, and the thermal conductivity - four times inferior - compared to aluminium alloys The use of steel doors and windows originates in old artisan traditions though it developed more significantly in the second half of the nineteenth century, on the wave of the industrial revolution. The Bauhaus movement of the nineteen-twenties and thirties definitively consecrated steel as an indispensable component for architecture: subsequently, in...

Open the catalog to page 9

Secco Sistemi has developed a process of oxidization of corten that allows to achieve the desired finish and chromatic effect the resistance of corten to corrosion is from 6 to 8 times superior compared to traditional steels while its resistance to tensile stress is double Corten steel appeared in the middle of the nineteen-thirties and was used prevalently in the field of heavy carpentry or in the realization of sculptures. More recently it has become more appreciated in the field of architecture for its material and chromatic characteristics as well as its structural resistance....

Open the catalog to page 10

index of materials painted galvanised steel oxidised corten steel waxed oxidised corten steel burnished brass satin-finished brass polished stainless steel scotch brite stainless steel satin-finished stainless steel burnished stainless steel material physical properties reference standards surface treatments Profiles obtained from strips of hot-rolled, galvanised steel sheet metal, skinpassed with Sendzimir finish system. Profiles obtained from strips of corten steel, a high-resistance and self-passivating metal, so as to form a uniform layer of oxide if exposed to air which covers...

Open the catalog to page 11

ABDR, Tadao Ando, Archea, Arup, BBPR, David Chipperfield, Antonio Citterio, Foster + Partners, Massimiliano Fuksas, Zaha Hadid, Herzog & de Meuron, Rem Koolhaas, Giovanni Michelucci, Pier Luigi Nervi, Jean Nouvel, Renzo Piano, Gio Ponti, RCR Arquitectes, Carlo Scarpa, Tobia Scarpa, Wilmotte & Associes... Secco Sistemi has worked with the masters of contemporary architecture and collaborates with professional figures from all over the world, sharing with them the passion for materials, the extreme care for detail and the culture of the project itself

Open the catalog to page 12

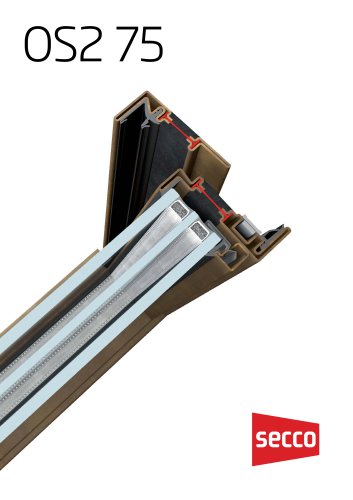

thermal break windows and doors OS2 65 Thermal break steel window for glazing of thicknesses up to 40 mm, profiles of 27 mm and central section 62 mm tubular profile windows and doors Thermal break steel window for glass of thicknesses up to 50 mm, profiles of 27 mm, central section 62 mm with tilt & turn mechanism EBE thermal break system, depth 65 mm for glass thickness of up to 48 mm, rebated on the interior and flush-mounted on the exterior between sash and frame EBE thermal break system, depth 75 mm for glass thickness of up to 48 mm, flush-mounted on the exterior and on the interior...

Open the catalog to page 13All SECCO SISTEMI catalogs and technical brochures

-

ebe 65, 4f 2 secco sistemi

1 Pages

-

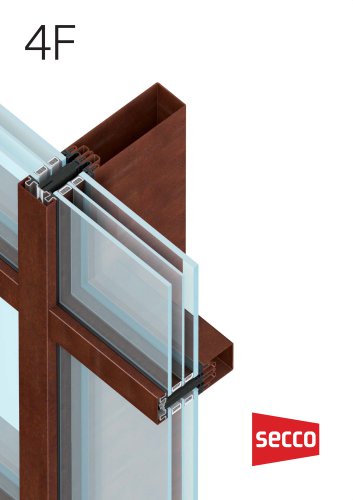

4F

72 Pages

-

OS2 75

13 Pages

-

Intra et Extra

276 Pages

Archived catalogs

-

2014 General Catalogue

204 Pages

-

Intra - Extra

139 Pages

-

General catalogue

180 Pages