Catalog excerpts

SBH TRENCH SHORING State-of-the-art trench shoring solutions for all excavation projects

Open the catalog to page 1

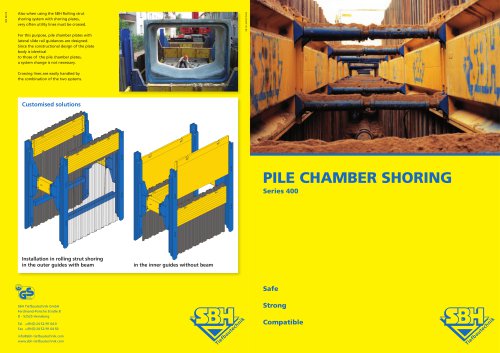

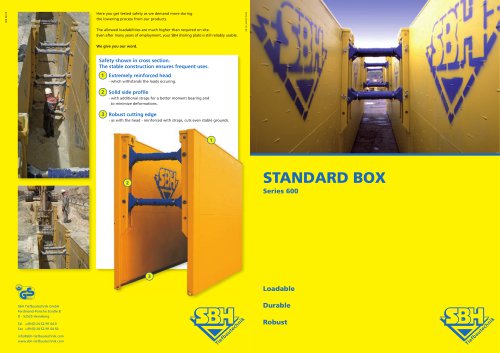

Company Profile Functions and benefits of large-scale shoring 6 An overview of shoring planning Pipe clearance heights and working space widths 9 Trench depth and choice of shoring system 11 Structural engineering calculations- a special service from SBH 12 Shoring systems using the place and adjust method Place and adjust method 16 Quick shoring Series 260 17 Aluminium shoring Series 250 18 Lightweight shoring Series 100 20 Shoring systems using the cut and lower method SBH spindles with slot together extension pipes 24 Standard box with transformation profile Series 260 29 Rolling Strut...

Open the catalog to page 2

Innovative production techniques and extensive automation of major processes not only ensures that production runs smoothly at all times but also that we are always able to provide the same high quality which our customers have come to expect. All the sheet piles made by SBH are manufactured in our in-house rolling mill. The commitment we have to both the location of our company headquarters in Germany and the need for state-of-the-art manufacturing facilities with cutting-edge technology enables us to react quickly, effectively and reliably to any changes in the market or our customers’...

Open the catalog to page 3

FUNCTIONS AND BENEFITS OF LARGE-SCALE TRENCH SHORING Cost Effective Work Processes Less Filling In and Compacting When and why are shoring systems used? Making excavations safe Large-scale trench shoring systems are excellently suited for this purpose. SBH Trench Shoring Systems are approved by BG BAU – the German Social Accident Insurance Institution for the Building Trade – and are either GS approved and/or issued with a Type Examination Certificate. This certification is based on extensive, certified structural calculations, which are partially substantiated by extensive trials and...

Open the catalog to page 4

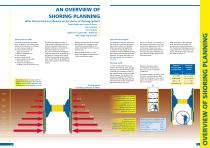

AN OVERVIEW OF SHORING PLANNING What factors have an influence on the choice of shoring system? Trench Depth and Course of Terrain Soil Conditions Ground Water Additional Loads (Traffic / Buildings) Pipe Length and Diameter Earth pressure loads The earth pressure load increases with the depth of the trench. Other factors which also have an influence on earth pressure loads are: ➥ course of terrain along edge of excavation ➥ slopes or embankments ➥ soil conditions ➥ ground water levels ➥ loads arising from building site traffic or tracks ➥ loads from foundations of buildings close to...

Open the catalog to page 5

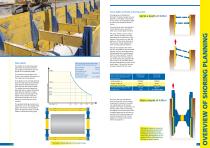

Trench depth and choice of shoring system Shoring Boxes or Rolling Strut Shoring? The type of system you use depends on the depth of the trench. In our opinion, the installation depth at which a line should be drawn is 4.00 m. This may, however, make it impossible to lower the sides of the box alternately all the way down to the bottom of the trench or to pull the plates out of the trench because of the excessive friction between the earth and the plates themselves. Plate lengths An example from the field with SBH Series 750 Rolling Strut Shoring The length of the individual pipes...

Open the catalog to page 6

SBH QUESTION AND ANSWER FORM Name of company: Structural engineering calculations – a special service from SBH Email address: SBH is happy to provide you with support for your individual project and structural engineering calculations for your construction site. FL bL Pipe diameter Trench width CROSS SECTION DESCRIPTION OF CONSTRUCTION SITE Pipe length Strut clear. height hC aF SLOPE Distance to bottom of slope In order to be able to provide you with a sound and reliable structural engineering analysis, we need to ensure that any influencing factors which have been established at the...

Open the catalog to page 7

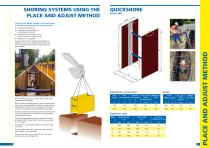

SBH SHORING PORTFOLIO CUT AND LOWER METHOD PLACE AND ADJUST METHOD for stable soil for stable and unstable soil Aluminium Shoring Lightweight Shoring recommended recommended recommended up to 2.00 m up to 2.40 m up to 3.00 m Required construction machinery none Trench boxes Boxes for large pipe diameters Special boxes Rolling Strut Shoring Single slide rail Double slide rail Pile chamber shoring box profiles pushed in hydraulically Pipe grab in combination with KD6/8 trench sheets Trench sheet Light Box Extra Box Standard Box transformation profile Maxi Box RS Box mini excavators mobile...

Open the catalog to page 8

SHORING SYSTEMS using the place and adjust method 1.00 The place and adjust method is only permissible if the following requirements have been met: temporarily stable ground outside the area of influence of any buildings or structures outside the area of influence of any roads or pipes which could be at risk settlements are acceptable The ground is deemed to be temporarily stable if no significant cave-ins occur during the period from the time the excavations start to the time the shoring has been installed. Aluminium corner post The Shoring Box is placed in a trench which has been...

Open the catalog to page 9

aluminium shoring Series 250 Trench edge support Aluminium plates Aluminium posts Pipe clearance length L C Pipe clearance height h C max. perm. earth pressure Weight with strut B Weight manhole Aluminium struts Strut type max. perm. compressive force place and adjust method

Open the catalog to page 10

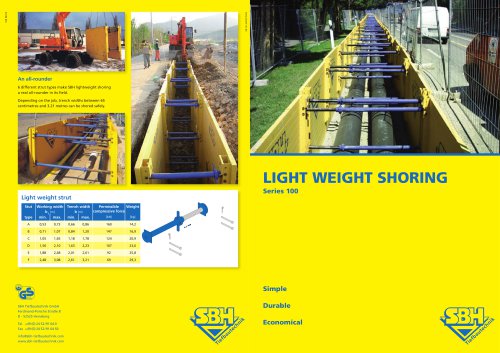

LIGHTWEIGHT SHORING Lightweight strut Strut Working width Trench width max. perm, com- Weight

Open the catalog to page 11

SHORING SYSTEMS USING THE CUT AND LOWER METHOD If the soil is unstable, the shoring box is installed by lowering it into the trench and alternately pushing the sides downwards. Installing the top boxes Top boxes are used for deeper trenches. The boxes are pre-assembled so that their width matches the width of the trench. Attach certified chains to the lifting eyes on the posts of the top box, align the box over the base box and connect both boxes using box connectors and pins. Continue the installation as previously described by alternately excavating and then pushing down the plates....

Open the catalog to page 12

with slot together extension pipes for different trench widths Other systems use extension pipes or connecting pieces which have to be laboriously screwed together. This not only costs time but also requires a large amount of screws. The system used by SBH is different. The pipes are simply slotted together and secured with a single spindle pin and an R-clip. The plates and the spindles are connected via a joint-mounted spring spindle holder. This allows the plates to be pushed alternately into the trench when the cut and lower method is used. Spindles for extremely high loads The spindles...

Open the catalog to page 13All SBH Tiefbautechnik catalogs and technical brochures

-

PRESSBOX SERIES 800

1 Pages

-

ROLLING STRUT SHORING

4 Pages

-

STANDARDBOX SERIES 600

2 Pages

-

ALUMINIUM SHORING

2 Pages

-

QUICK SHORE

2 Pages