Catalog excerpts

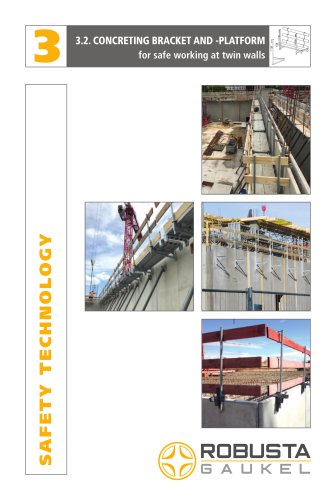

3.2. CONCRETING BRACKET AND -PLATFORM for safe working at twin walls

Open the catalog to page 1

CONCRETING BRACKET AND -PLATFORM FOR TWIN WALLS GENERAL INFORMATION Your benefits at a glance: G Serves as temporary scaffolding to be able to stand safely without danger of falling when installing concrete G Dangerously standing or walking on narrow concrete formwork or on ladders is unneeded, along with other improvisations G Can be fixed without concreting anchors in; no prior planning needed G Rapid mounting and dismantling due to handy individual parts G Plug-in railings can be inserted easily for fall heights above 2 m Concreting bracket and working platform for twin walls – for each...

Open the catalog to page 2

CONCRETING BRACKET AND -PLATFORM FOR TWIN WALLS ANCHORING TECHNOLOGY Most simple fixing for brackets and working platforms: The universal advantage: concreted anchoring parts are not necessary, the brackets can be hanged into any spot. This guaranties independence from planning and pressures during work cycle of construction. The bracket for twin walls can be attached to any spot with the hang in core into the gap of the element wall. A plastic tube will protect the core against concreting and contaminating, the pulling out of the core off the hardened concrete is possible without any...

Open the catalog to page 3

CONCRETING BRACKET AND -PLATFORM FOR TWIN WALLS CONCRETING BRACKET Examples for use Available are single brackets, which can be installed and removed by hand and have to be completed with floor timbers and side protection boards on site. Example: element wall alone: at external walls the attachment in is possible at the internal as well as at the external panel concreting bracket and working platform for twin walls

Open the catalog to page 4

CONCRETING BRACKET AND -PLATFORM FOR TWIN WALLS CONCRETING WORKING PLATFORM Examples for use For bigger constructions with many concreting steps the pre-mounted working platforms are more suitable. A quick changing of the working platforms with the crane helps to save time and costs. Products subject to technical changes

Open the catalog to page 5

CONCRETING BRACKET AND -PLATFORM FOR TWIN WALLS CONCRETING WORKING PLATFORM Easy mounting: The working platform for twin walls has been developed continuously from the already proven single brackets. On site a complete working platform is available immediately ready for use, the laying of floor timbers on site is no more necessary. The practical folding mechanism guarantees a simple and secure installation and avoids mounting faults. For mounting a working platform unit it will be lifted with the crane for approx. 1 meter, both brackets will be set upright and with both inserted side rail...

Open the catalog to page 6

CONCRETING BRACKET AND -PLATFORM FOR TWIN WALLS CONCRETING WORKING PLATFORM After inserting the 3 side security boards a functional working platform is available. Each working platform offers the possibility to insert 2 more rail posts at the front side, so it is always possible to mount a safe edge protection to the first and the last working platform. For economical transportion of the working platform units with a truck the brackets are made that a very space saving folding and stacking is possible. The 4 impact points at the corners can also be used for centering and as a distance...

Open the catalog to page 7

CONCRETING BRACKET AND -PLATFORM FOR TWIN WALLS CONCRETING WORKING PLAFORM Further development of the cavity wall concreting platform In an alternative version of the cavity wall stage, the wooden covering was replaced by a hot-dip galvanized steel covering. The rough profiling of the knobs pressed up ensures a much better stability and slip resistance. In addition, standing water can be avoided by this improvement, since it can run off better thanks to the new profiling. ADVANTAGE: The stages with wooden or steel floors are 100% compatible and can therefore be stacked on top of each other...

Open the catalog to page 8

CONCRETING BRACKET AND -PLATFORM FOR TWIN WALLS CLAMP FOR TWIN WALLS Accessory: clamp for twin walls A simple solution for a quick mounting of the edge protection at twin walls during armoring works and concreting of slabs. Also for the clamp for twin walls the plastic installation kit has to be used. The big advantage: During the concreting of the slab the clamp for twin walls guarantees a safe protection with the inserted railing post. After hardening of the concrete the clamp for twin walls can be dismounted immediately and be used again for the next stage. So the plastic installation...

Open the catalog to page 9

CONCRETING BRACKET AND -PLATFORM FOR TWIN WALLS GENERAL INFORMATION TECHNICAL DATA: Concreting bracket Item No. set complete: bracket for twin walls with railing posts – max. single load: 150 kg / bracket – max. area load: 150 kg / m2 – max. distance of brackets: 1.50 m, min. distance of edge to joint 25 cm – concrete panel: min. 5 cm, max. 9.5 cm thick – wooden timbers: floor timbers min. 20 x 3.5 cm – side protection: 3 or 4 wooden timbers 15 x 3 cm Weight [kg/unit] to hang in at the internal or external side, hot galvanized. Plastic installation-kit with special plug Weight [kg/unit]...

Open the catalog to page 10

CONCRETING BRACKET AND -PLATFORM FOR TWIN WALLS ALLGEMEIN TECHNICAL DATA: Clamp for twin walls Weight [kg/unit] Concreting working platform complete with falling protection for the back side Weight [kg/unit] working platform completely mounted consisting of 2 brackets with floor timbers 75.0 falling protection for the back side consisting of 2 side protection railing posts and 3 wooden timbers L = 2,40 m, delivered separately 30.0 optional: falling protection for the front side, consisting of 2 side protection railing posts and 3 wooden timbers 16.0 Concreting working platform, steel floor,...

Open the catalog to page 11

Berlin office: Date of issue: January 2020

Open the catalog to page 12All ROBUSTA-GAUKEL GmbH & Co. KG catalogs and technical brochures

-

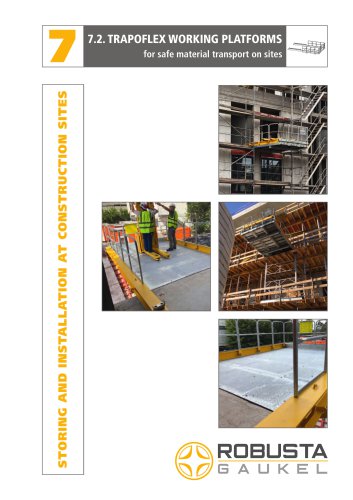

7.2. TRAPOFLEX WORKING PLATFORMS

12 Pages

-

7.1. DEPOFLEX STORAGE RACKS

16 Pages

-

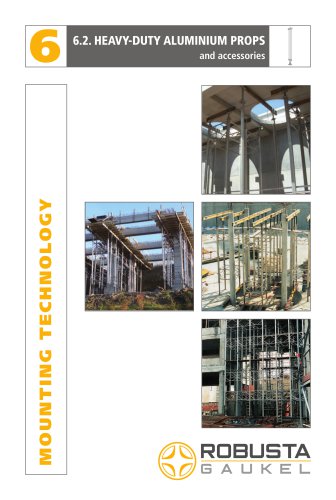

6.2. HEAVY-DUTY ALUMINIUM PROPS

20 Pages

-

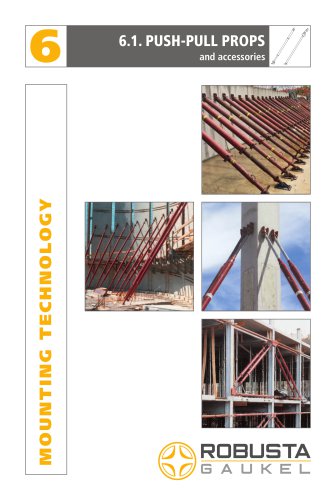

6.1. PUSH-PULL PROPS

24 Pages

-

5 . 4 . RAPID LOCKING NUT

8 Pages

-

5 . 1 . PROFILE LEDGES

8 Pages

-

4.2. SPECIAL FORMWORK

24 Pages

-

4.1. ROUND COLUMN FORMWORK

12 Pages

-

3.6. MULTI WALKWAY

8 Pages

-

3.4. SAFETY BARRIER

28 Pages

-

3.3. RAILING SUPPORTS

32 Pages

-

2.1. NON-RECOVERABLE FORMWORK

12 Pages

-

1.1. THREADED SLEEVES

24 Pages

-

5 . 3 . A N G L E C O N E

8 Pages

-

1.3. ANCHORING SET

12 Pages