Catalog excerpts

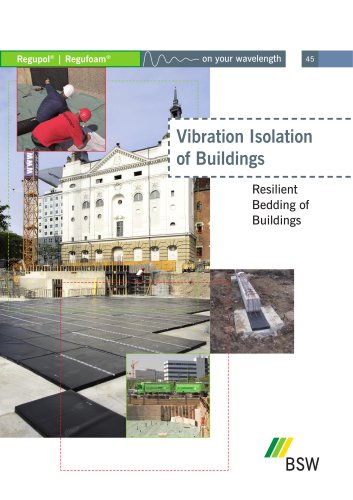

Vibration Isolation of Buildings Resilient Bedding of Buildings

Open the catalog to page 1

Vibration Technology Vibration Isolation of Building Foundations Various factors may subject buildings to shock which continues in their structure and is perceived by the people living in them as noticeable vibrations or secondary airborne noise. Specifically in areas with a dense infrastructure, these are typically vibration emissions from above- or underground railway lines and from industrial plants. Regupol® and Regufoam® are suitable for all kinds of vibration isolation of buildings: Especially the high prices of land in conurbations also make locations next to railway lines attractive...

Open the catalog to page 2

Vibration Technology The protection of buildings against vibrations can be achieved through different measures: The vibrations which are caused by the source of the shock may spread throughout the building structure: they are perceived as noticeable vibrations, they can spread as secondary airborne sound, and when the worst comes to the worst, they can damage the building structure. What is more, the function of machines and measuring equipment in the building may be impaired. The objectives of the vibration isolation of buildings are: – health protection – the protection of the building...

Open the catalog to page 3

Vibration Technology Types of Vibration Isolation of Buildings The decision of which measures to take always depends on various impact factors and must be taken based on the individual case. The vibrations to be expected at the place of immission (the building) depend on the composition of the frequency of the emission source, on the transmission via the specific ground, the coupling of the building and the continuation of the vibrations within the building structure. Transmission Mechanism As a rule, the existing situation should be assessed by taking vibration measurements. With the help...

Open the catalog to page 4

Vibration Technology Full-Surface Decoupling In full-surface decoupling, the entire base plate is separated elastically from the building ground. The elastomer is either applied on a thicker foundation course or on a specially dimensioned supporting plate. To achieve optimum efficacy, the foundation should be as rigid as possible. Since it is a full-surface installation, the isolation can be performed quickly and easily, and the risk of acoustic bridges is very low, too. The building loads are distributed over a large area of the subfloor. The degree of rigidity of the elastomers is...

Open the catalog to page 5

Vibration Technology Strip Decoupling Linear decoupling is a vibration isolation option for buildings with strip foundations. The width of the foundation should be such that the elastomers are used optimally by the load-bearing area to make sure that the best isolation effect can be achieved. An alternative option is strip decoupling on the rising walls underneath the basement ceiling. With this method, it is also possible to do without vertical isolation of the exterior structural components towards the ground. The adjoining structural parts, such as ceilings on top of the structural part,...

Open the catalog to page 6

Vibration Technology Point Decoupling Because of the high point loads in foundations with poles and supports, elastomers with a high load-bearing capacity are typically used for vibration decoupling. The elastomers should already be included in the plan at an early stage to make sure that the vibration isolation can increase the security of the entire structure. The pile cap structure can be optimised by keeping the pressure on the elastomer constant by varying the measurements. The result is an even deformation and isolation behaviour of the entire foundation construction and the...

Open the catalog to page 7

Vibration Technology Vertical Decoupling In some cases it suffices to install a vertical partition at the exterior structural components in order to reduce vibrations. Vertical partitions are often installed between existing and to-be-constructed buildings. In these applications there are diverse requirements of the elastomer. The more dynamically soft the material, the better the reduction of the vibration. However, it still has to be able to bear the loads that occur. These loads, which may be the result of earth or concreting pressure, may be up to 120 kN/m2 and in exceptional cases...

Open the catalog to page 8

Vibration Technology Mounting Gluing The vertical isolation can be glued onto the partition wall. To this end the construction site must offer the usual gluing conditions such as a dry and dust-free surface. Mechanical Mounting Alternatively, the material can be nailed or plugged onto the wall with mounting aids, regardless of the weather conditions. Execution (Example)

Open the catalog to page 9

Your contact to BSW GmbH BSW Berleburger Schaumstoffwerk GmbH Am Hilgenacker 24 57319 Bad Berleburg Germany Phone +49 2751 803-0 info@berleburger.de www.berleburger.com www.bsw-vibration-technology.com Made in Germany The technical information given in the documents are guideline values. They are liable to manufacturing tolerances, which may vary depending on the type of underlying properties. The currently valid versions of this information are provided on our internet pages and in the PDF versions of this catalogue. The PDF versions are available to download from our website. We do not...

Open the catalog to page 11All REGUPOL Germany GmbH & Co. KG catalogs and technical brochures

-

REGUPOL PLAYFIX BOLLARD

3 Pages

-

REGUPOL PLAYFIX EDGING

3 Pages

-

REGUPOL EVERROLL ESSENTIAL

2 Pages

-

REGUPOL winter sports flooring

19 Pages

-

REGUPOL climbing hall flooring

48 Pages

-

REGUPOL fitness flooring

35 Pages

-

REGUPOL Athletics Tracks

23 Pages

-

REGUPOL Equestrian Flooring

54 Pages

-

REGUPOL SOUND 15

3 Pages

-

REGUPOL SOUND 17

4 Pages

-

REGUPOL VIBRATION 200

6 Pages

-

REGUPOL VIBRATION 400

6 Pages

-

REGUPOL VIBRATION 550

6 Pages

-

MIXED-USE BUILDINGS

15 Pages