Catalog excerpts

CONTENT 1 MODEL PREPARATION 2 FRONT LAYERS, POURING TECHNIQUE 3 FRONT LAYERS, BRUSHING TECHNIQUE 3.1 4 BONDING LAYERS, PRIMER LAYER 4.1 FLEXIBLE FRONT-LAYER 5 BACKINGS, EPOXY MORTAR 5.1

Open the catalog to page 4

6 SUPPORT MOULDS, GRP TECHNIQUE 7 GYPSUM RELEASE AGENT 8 ADHESIVE FOR MOULD MAKING PRODUCT OVERVIEW

Open the catalog to page 5

1 MODEL PREPARATION RECKLI MOULD WAX Application The release agent are ready-to-use and can be brushed or sprayed. For a safe release 2-3 layers are to be applied. Before application of a following layer the preceding one must be completely dry. Consumption approx. 50 g/m2 Mould preparation 1.0 Stop-off frame

Open the catalog to page 6

2 FRONT LAYER POURING TECHNIQUE RECKLI PUR-ELASTOMER K Property elastic Application Preparation of the surface according to 1. RECKLI PUR Elastomer K is a two-component liquid resin curing nearly free of shrinkage. Hardener and base component are mixed thoroughly and poured on to the model surface (s. technical data sheet). Layer thickness depending on thecase of application 10-20 mm Consumption approx. 1.35 kg/l Pot life approx. 15 minutes (200 g) Opening for pouring Backing 5.1, 5.2 Airing Front pouring layer 2.0 Case-mould preparation 1.0 Stop-off frame Case-mould Block-mould

Open the catalog to page 7

3 FRONT LAYER BRUSHING TECHNIQUE 3.1 RECKLI EPOXY OH RECKLI EPOXY OH SCRATCH-RESISTANT Property hard Application RECKLI Epoxy OH is a hard, impact-resistant gelcoat resin being applied onto the model surface in two layers. We suggest to add a small quantity of pigment paste to one of the layers, so that the layer thickness can be controlled easier. Total layer thickness approx. 2-3 mm A bonding layer is applied between the Epoxy OH gel-coat layer and the backing (v. 4.2). The backing is stamped into the wet bonding layer (v. 5). Consumption approx. 1.5 kg/m2 per mm layer thickness Pot life...

Open the catalog to page 8

3.2 FRONTSCHICHT STREICHTECHNIK 3.2 RECKLI PUR ELASTOMER THIX Property elastic Application RECKLI PUR Elastomer thix is a two-component putty resins. RECKLI PUR Elastomer thix results into a layer thickness of approx. 1 mm per operation. A bonding layer (v. 4.1) is to be applied between frontlayer and backing (v. 5). Consumption approx. 1.4 kg/m2 per mm layer thickness Pot life approx. 8-10 minutes (200 g) Backing 5.1, 5.2 Bonding layer 4.1 Front-layer 3.2 Case-mould preparation 1.0 Stop-off frame Case-mould Block-mould

Open the catalog to page 9

4 BONDING LAYERS PRIMER LAYER 4.1 RECKLI CONSTRUCTION RESIN EP RECKLI EPOXY PB Surface flexible front-layer Working steps The bonding layer’s function is to form a strong and firm bond between the cured, elastic front-layer of RECKLI PUR Elastomer or RECKLI PUR Elastomer thix and the backing. The best bonding values are achieved, if glass fibres are added to and mixed with RECKLI Construction Resin EP or RECKLI Epoxy PB until there is a pasty consistency like sauerkraut. This pasty mass is manually applied onto the front-layer, whereas the hands are to be protected by rubber gloves. The...

Open the catalog to page 10

4.2 KOPPLUNGSSCHICHTEN PRIMERSCHICHT 4.2 RECKLI CONSTRUCTION RESIN EP RECKLI EPOXY PB Surface hard front-layer Working steps In order to get a bonding layer for hard surfaces, a certain quantity of quartz powder depending on the powder’s ingredients is added to RECKLI Construction Resin EP or RECKLI Epoxy PB until there is a pasty, consistency suitable for painting. This filled resin mass is painted onto the hard front-layer. Layer thickness approx. 2-3 mm The backing material is stamped intothis fresh bonding layer. Recipe Construction Resin EP or Epoxy PB Quartz powder W 1 Consumption...

Open the catalog to page 11

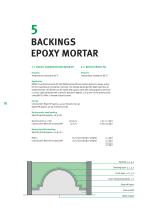

5 BACKINGS EPOXY MORTAR 5.1 RECKLI CONSTRUCTION RESIN EP Property Temperature resistance 40 °C Property Temperature resistance 90 °C Application RECKLI Construction Resin EP and RECKLI Epoxy PB are binders based on epoxy resins for the manufacture of polymer concrete. For making backings with high exactness of measurements, the binder can be mixed with quartz sand with varying grain sizes from 0.2 mm. Light backings with a specific gravity of approx. 0.6 g/cm3 can be produced by using RECKLI Filler L instead of quartz sand. Pot life Construction Resin EP approx. 40-50 minutes (200 g) Epoxy...

Open the catalog to page 12

6 SUPPORT MOULDS GRP TECHNIQUE RECKLI EPOXY SUPPORTING MASS EP-F TYPE VB Property GRP Stamping Material, Temperature resistance 75 °C Application For manual production of thin-walled support moulds we suggest to firstly paint the fine layer RECKLI Epoxy OH onto the model surface before putting on the nearly dry stamping mass EP-F Type VB (consistency like sauerkraut). The closed fine layer smoothens the rough-fibred bearing layer EP-F Type VB on the surface. This makes releasing and cleaning easier and reduces the danger of injuries by protruding fibres. The front and the back side are to be...

Open the catalog to page 13

7 GYPSUM RELEASE AGENT RECKLI GYPSUM RELEASE AGENT GTM Proberty Release Agent Application RECKLI Gypsum Release Agent GTM is a water-based, release agent with only little affects to the environment. It is used for release between block-mould surfaces made of RECKLI PUR Elastomers, RECKLI silicone rubbers or RECKLI epoxy resins and plaster. When this release agent is used, there is no swelling of the block-mould surfaces. The absorption capacity of the gypsum mould is hardly affected. Stop-off frame Cover mould 6.0 Gypsum Release Agent 7.0 Plaster (working mould) Gypsum Release Agent 7.0...

Open the catalog to page 14

8 ADHESIVE FOR MOULD MAKING RECKLI ADHESIVE PASTE EP Property Adhesive paste free of solvents, two components Application For low-tension adhesion of hard foam, timber, gypsum, ceramics, especially suitable for gluing of large-volume hard-foam blocks being used for computer-aided design (CAD) of models. Consumption approx. 800 g/m2 Pot life approx. 40-50 minutes (200 g) 9 PRIMER FOR GYPSUM RECKLI CONSTRUCTION RESIN EP Property Bonding agent between gypsum and RECKLI PUR Elastomer Application Bonding agent between gypsum and a front cast of RECKLI PUR Elastomer. A maximum drying time of 3-4...

Open the catalog to page 15

VISCOSITY MPA.S nearly free of shrinkage nearly free of shrinkage LINEAR SHRINKAGE % MIXING RATIO BY WEIGHT PRODUCT OVERVIEW POLYURETHANE-ELASTOMERS, POURABLE RECKLI PUR Elastomer K solvent-free, rubbery-elastic, liquid, two-component polyurethane, cold-curing, almost shrinkage-free, after curing sliceable and grindable. Hardness: 60 Shore A, Color: grey POLYURETHANE-ELASTOMERS, PUTTY RESINS RECKLI PUR Elastomer thix two-component compound, thixotropic, paste-like, especially suitable for moulding on vertical surfaces Notes as to Consumption Rates and Pot life The consumption rates we...

Open the catalog to page 16All RECKLI GmbH catalogs and technical brochures

-

Formliners

136 Pages

-

WetCast

12 Pages

-

Photo-Engraving Formliners

16 Pages

-

3D-Béton

12 Pages

-

Lookbook

11 Pages

-

Artico Neo

36 Pages