Website:

RECKLI GmbH

Website:

RECKLI GmbH

Group: RECKLI GmbH

Catalog excerpts

Application Guide Line for RECKLI-Formliners

Open the catalog to page 1

3 1. Classification We distinguish our formliners with the prefix numbers 1/.. and 2/.. The most important distinguishing features are listed in table 1. There is also available another type of formliner with the prefix number 3/.. These formliners are for one use only. This working guide applies only to the formliners with the pre fix1/.. and 2/.. For the OneTimer Formliners prefix number 3/.. there is a separate catalogue with the relevant guide. 2. Material The formliners consist of rubber-like Polyurethane Elastomers. The high flexi bility and elasticity allow a damage-free release of...

Open the catalog to page 3

4 8. Pattern Design There is no intended repeatability (with the exception of any of the rib type patterns) in the formliner patterns within the maximum mould size as compared to wallpapers. A number of patterns are designed in a way that they can be placed together side by side continuously. With a little care the joints in the patterns can be made almost invisible. (Picture 4+5) For the building of our master moulds we use a combination of natural and man made materials of commercial grade quality which are formed using current standard working practices. Unavoidable tolerances,...

Open the catalog to page 4

5 RECKLI- Formliner Knife. For a straight cut line please use a metal or timber straight edge. (Picture 7) When cutting thicker pattern formliners do not try and make the cut ‘in one’ place the knife in the first cut and draw through the formliner gently as many times as required, do not use excessive force as this will lead to crooked cuts. We do not advise cutting these formliners with a circular power saw. Note: It is very difficult to make mitred, bevel cuts with a knife to an unfixed formliner. When such bevels are required we can suggest two methods: a) place the area to be mitred...

Open the catalog to page 5

6 11. Application for In-situ Concrete 11.1. Fixing by adhering When used for in-situ concrete the form - liners must be glued down. (see 12.) 11.2 Fixing by nails For minimum use or the immediate change of shutter sizes after the first pour, the formliners with prefix number 1/.. can be nailed onto the formwork. The nail centres should be approx. 20-25 cm. Use ‘lost heads’ or ‘ovals’ nails so that it is possible to pull the nail heads through the formliner during stripping/striking. Depending on the pattern or texture always nail through the high points of the pattern. This will ensure...

Open the catalog to page 6

7 12.3.1 Timber The most suitable foundation for RECKLIFormliners are new clean untreated plywood sheets designated as suitable for shuttering. (Picture 19) Resin coated plywood plates must be ground off to the rough timber surface. 12.3.2 Steel Steel must be rust free and the work will benefit from a light sand-blast. If this is not possible the minimum should be the use of an angle grinder to the surface. When using RECKLI Formliner Adhesive SO no primer is required. 12.4 Adhering 12.4.1 Formliners with prefix number 1/.. 12.4.1.1 Roughening of the formliner rear Lay the formliners onto...

Open the catalog to page 7

8 12.4.1.4 Gluing onto vaulted or curved surfaces The formliners 1/.. are flexible and can be deformed to various degrees to accommodate shutter and mould shapes but because they are flexible and have a ‘spring‘ value you will have to support/contain the formliners to the shutter/mould profile until the adhesive cures. To reduce the ‘spring’ in the formliner you can cut kerfs in the rear of the formliner which makes curving the formliner easier, on extreme curves you can cut V’s in the back of the liner. The depth of these cuts will depend on the thickness of the formliner. Cut only into...

Open the catalog to page 8

9 13. Release Agents 13.1 Choice of release agent The choice and application of the correct release agent is most important to obtain an efficient release and high a quality concrete finish. We supply three different release agents depending on the application. RECKLI-Stripping Wax TL contains solvents. RECKLI-Stripping Wax TL-W is water-based. These two release agents are more suited to pre-cast concrete. RECKLIStripping Wax TL-SO also contains solvents and is especially designed for in-situ concrete. (Table 2) 13.2. Application The stripping wax must be brushed or sprayed on a minimum two...

Open the catalog to page 9

10 16. Striking / Stripping 16.1 Striking / Stripping timing It is easier to release RECKLI-Formliners within 24 hrs of casting. Specification and striking times for your particular application should overrule RECKLI`s suggestion. 16.2 Unfixed formliners Formliners that are laid loosely in the mould will peel off of the concrete during stripping due to their weight. (Picture 11-13) If this should not happen due to the depth of pattern, peel off the liners carefully starting from a corner. Do not tear at the formliner, doing so could exceed its stretching capacity. 16.3. Adhered formliners...

Open the catalog to page 10

11 18. Joints / Corners / Edges 18.1. Use of profiled fillets Profiled fillets for shaping corners, edges and joints should be considered. You must calculate the thickness of the profile as to what part of the pattern it is required to be aligned to i.e., top, middle or bottom. The thickness of the formliner back must also be considered. (see sketch 1-5) (Picture 36- 39) Sketch 3 36 37 38 Butt joint formliner Sketch 4 Smooth frame with chamfer deep in concrete Sketch 5 Smooth frame with chamfer high in concrete Sketch 1 Chamfered cove, high in concrete Sketch 2 Chamfered cove, deep in...

Open the catalog to page 11

12 39 40 41 18.2 Formliner joints When placing formliners with coarse or rank patterns side by side care must be taken to see that the joints from this operation are sealed correctly. RECKLI-Formliner Adhesive can be used after you have glued the formliner down. You can also use standard building One Component Silicone applied to the formliner when the adhesive has cured. We do not advise butting or mitring formliners together for 90° corners for such kind of patterns. They will never look good. Make a feature at the corners by introducing a plain band to the pattern, the corner will look...

Open the catalog to page 12All RECKLI GmbH catalogs and technical brochures

-

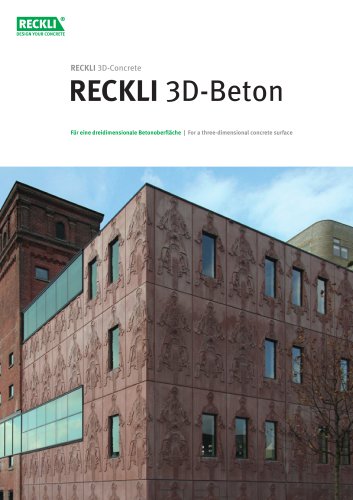

3D-Béton

12 Pages

-

Artico

47 Pages

-

Patternbook (Main catalogue)

356 Pages

-

RECKLI Graffix Basic GB

2 Pages

-

Photo-Engraving Formliners

16 Pages

-

RECKLI-Magazine “Formliner”

144 Pages

-

Hose and cable tunnels

4 Pages

-

Custom-Made Formliners

8 Pages

-

Material for Block-Moulds

12 Pages

-

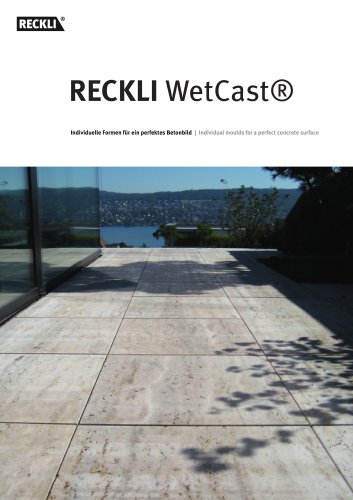

WetCast

4 Pages

-

3D-Formliners

4 Pages

-

Trends

12 Pages

-

RECKLI One Off Formliners

8 Pages

-

Application Guide Line

16 Pages

-

Moulds and reproductions

36 Pages

-

Mini Catalogue Formliners

56 Pages

-

Baluster moulds

12 Pages

-

Formliners

372 Pages

Archived catalogs

-

One-Timer Formliner

36 Pages

-

Nawkaw Staining

8 Pages

-

RECKLI One Timer Formliners

36 Pages

-

Catalogue references

68 Pages