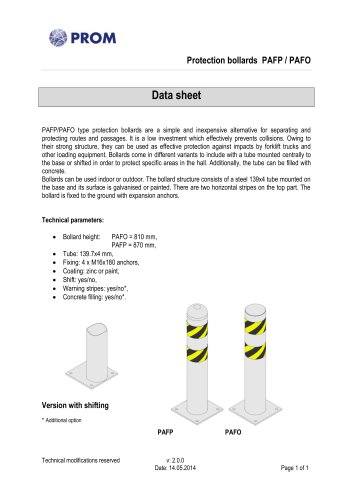

Catalog excerpts

Dock leveller with hinge lip PS Data sheet Technical modifications reserved

Open the catalog to page 1

Dock leveller with hinge lip PS Technical modifications reserved

Open the catalog to page 2

Dock leveller with hinge lip PS 1. General information The PS-type dock leveller with hinge lip is a result of many years of experience in manufacture of levelling systems and the output of a highly qualified research and development team. Use of higherstrength steel allowed for reduction of the leveller weight, while maintaining its great strength and durability. During loading and unloading operations the leveller automatically adapts to the height fluctuations of the vehicle bed (smooth adjustment system) and perfect torsional flexibility ensures safe and comfort loading of goods. The...

Open the catalog to page 3

Dock leveller with hinge lip PS • Nominal lengths (NL): 1750, 2000, 2500, 2750, 3000, 3500, 4000, 4500 mm • Nominal widths (NW): 1750, 2000, 2100, 2200, 2250, 2400 mm • Leveller height (LH): 600, 700, 800, 900 mm • Nominal lip lengths (LL): 400, 500 mm • Nominal capacity: 6 ton (60kN) • Operating ranges above level: 0 - 570 mm • Operating ranges below level: 0 - 350 mm • Thickness of the upper sheet of the platform: tread plate 6 mm (6/8) or optionally 8 mm (8/10) • Platform options: anti-slip coating, insulation, EPDM gasket • Lip sheet thickness: tread plate 13 mm (13/15) • Lip options:...

Open the catalog to page 4

Dock leveller with hinge lip PS • Optional corrosion protection: painting with RAL pallet paints 160 pm, hot-dip galvanizing, duplex (hot-dip galvanizing and painting) • Motor power: 0.75 kW • Power supply: 3~400 V, N, PE / 50Hz / 16A • Control system tightness degree: IP65 • Standard functions of the control system: one control button, main switch, door sensor connector • Optional functions of the control system: LCD, indicator light control, air sealing automatic control, air sealing manual control, sealing blind control, PROM door control, vehicle sensor control, door release signal,...

Open the catalog to page 5

Dock leveller with hinge lip PS 2. Hinge lip The lip of the PS-type dock leveller is made of high quality tread plate with thickness of 13 mm (13/15) and equipped with a special, solid, contamination-resistant and almost maintenance-free system of hinges. The structure of the resting supports ensures a safe distance between the lip and the frame bar which prevents potential hand injuries. There is a wide range of optional lip designs available: Standard lip Bevelled lip Standard solution. Suitable for most loading operations of typical size vehicles. Lip symmetrically cut on both sides by...

Open the catalog to page 6

Dock leveller with hinge lip PS FALL-GUARD interlock lip Bend lip This lip, at platform resting position, projects at a height of 90 mm, which is an obstacle, and at the same time protection against falling down the forklift from the ramp through the dock gate._ ensures good work ergonomics when the vehicle deck is both below and above the docking floor level. Solution for better work Straight lip ergonomics when the vehicle deck is below the docking floor level. Bevelling 40 mm Standard solution. It ensures good ergonomics for loading devices with large and soft wheels. Bevelling 100 mm...

Open the catalog to page 7

Dock leveller with hinge lip PS 3. Platform The platform of the PS-type dock leveller with load capacity of 60kN is made of high quality tread plate with thickness of 6 mm (6/8) and is intended to be used with standard, four-wheel forklift trucks with pneumatic wheels or so-called super elastic wheels. Optionally, the sheet thickness can be increased to 8 mm (8/10) to use the leveller with hard wheel devices such as electric pallet trucks. The upper sheet is reinforced from the bottom with special binders ensuring torsional flexibility of the platform. This ensures adhesion of the vehicle...

Open the catalog to page 8

Dock leveller with hinge lip PS 3.2 EPDM gasket In order to limit air infiltration through the dock leveller it can be optionally fitted with a gasket between the platform and the framing. This improves working conditions in the warehouse and ensures power saving. 3.3 Front screen Optional insulation of the platform ensured by panels with thickness of 40 to 60 mm reduces heat losses and the intensity of sounds transmitted by the device. It is recommended to apply insulation in combination with an EPDM gasket. Technical modifications reserved

Open the catalog to page 9

Dock leveller with hinge lip PS 3.4 Anti-slip coating (KVS) The platform and the lip of the PS-type dock leveller can be optionally finished with special anti-slip coating with thickness of about 4 mm, consisting of flexible polyurethane layer resistant to pressure and most chemicals, as well as of fine basalt aggregate. Such combination guarantees greater ergonomics and safety of work through much better traction for a forklift truck and reduction of the intensity of sound generated during reloading operations. Technical modifications reserved

Open the catalog to page 10

Dock leveller with hinge lip PS 4. Framing The framing provides connection of the dock leveller with the building and supports it in rest position. The PS-type dock leveller comes with a wide range of framing for each installation requirement ensuring so-called undercut for docking vehicles with a lift. 4.1 T-frame The dock leveller framing is filled with concrete. The frame around the leveller is equipped with a 200mm wall serving as a small formwork. This significantly facilitates concrete works. Quick and clean installation in one step is an advantage of this solution. PSE.00.00.01...

Open the catalog to page 11

Dock leveller with hinge lip PS 4.2 W-frame The dock leveller framing is welded to the previously prepared initial frame fastened in the building floor. This solution allows you to install the leveller after completing concrete works. Potential and easy replacement of the device in future is an additional advantage. Technical modifications reserved

Open the catalog to page 12

Dock leveller with hinge lip PS 4.3 F-frame The dock leveller framing is welded to the existing frame. With this design, the platform can be installed in a pit from which the old platform has been removed. Technical modifications reserved

Open the catalog to page 13All Promstahl catalogs and technical brochures

-

Mechanical dock shelter PMN

14 Pages

-

Loading Technology

36 Pages

-

Dock leveller with lip PT

27 Pages

-

External loading house PL

10 Pages

-

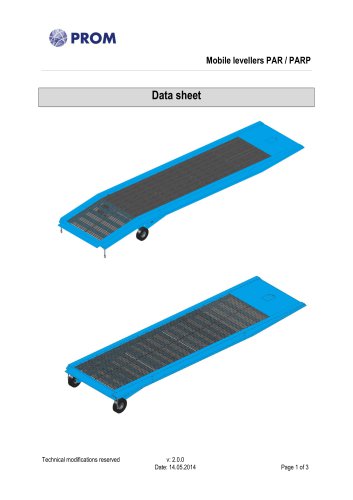

Mobile levellers PAR / PARP

3 Pages