Catalog excerpts

ecoPRESS EX1-01 Differential pressure transmitter The transmitter is used to measure the differential pressure value. Reading the pressure value and configuration of transmitter parameters is done by means of Modbus RTU protocol, in RS485 standard. Modbus registers include, among others, information on the currently set measuring range, time constant, percentage value of pressure difference related to the range and signaling of exceedances of the sensor’s measuring range. The transmitter enables reading the value of differential pressure with the use of voltage analogue output [0-10 VDC]. The transmitter cooperates with the ventilation system controllers and any industrial automation. Functions • • • • • • • • • • • • • • Built-in differential pressure sensor. Controlling of constant flow and detection of the degree of filter contamination. Converting differential pressure to flow. Analogue voltage output 0-10 VDC to read the value of voltage proportional to the measured pressure. Possibility of setting one of eight available ranges of voltage output 0-10 VDC. The LED indication of the operating status of the transmitter. Zero point calibration. Communication in the RS485 standard with any industrial automation. Wide range of transmitter power supply voltage. Cooperation with ventilation system controllers and configuration of transmitter parameters from the controller service menu. Supplying the transmitter from an external power supply or directly from the controller socket. Possibility of setting the time constant of measurement. Optional reading of values and configuration of transmitter parameters using Modbus RTU protocol. Installation on flat surface. Technical specifications Supply voltage / Current consumption Protection level / Protection class Ambient temperature Storage temperature Relative humidity 5…85%, without steam condensation Measuring range Measurement accuracy -500 Pa [±2.5 % range]; -2500 Pa [±1.5 % range]; -7000 Pa [±1.5 % range] Analog output Two analog outputs 0-10 VDC (one per each sensor) Digital transmission connector Screwed in 5 mm grid; wire cross-section from 0.5 mm2 to 1.5 mm2; tightening torque 0.4 Nm, isolation length 6 mm Dimensions (without dampers) Contamination level Software class PLUM Sp. z o.o. ul. Wspólna 19, Ignatki, 16-001 Kleosin, Poland plum@plum.pl www.plum.pl National Waste Database No. 000009381

Open the catalog to page 1

Specifications Configuration of the switch jumpers Electrical connection Pressure sensor 0-10 V DC/AC Analog output Supply Measurement range analog output Reset/restore factory defaults Example application Measurement of overpressure or underpressure Filter/Throttle Differential pressure measurement Fan Differential pressure measurement PLUM Sp. z o.o. reserves the right to introduce amendments in construction of the devices, without prior notice. Functions indicated above are for illustrative purpose only, they are adjusted depending on Manufacturer/Producer and software of system...

Open the catalog to page 2All PLUM Sp. z o.o. catalogs and technical brochures

-

SCP V

2 Pages

-

SVOC EX1

1 Pages

-

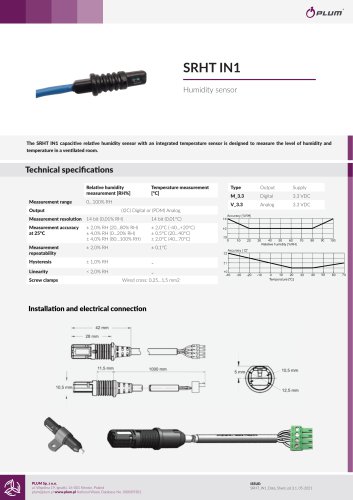

SRHT IN1

1 Pages

-

ecoPRESS EX1-02

2 Pages

-

MacBAT 5

4 Pages

-

ecoVENT

4 Pages

-

ecoVALVETRONIC

2 Pages

-

ecoSTER 200

2 Pages

-

eSTER_x40

2 Pages

-

ecoMAX 800R

2 Pages

-

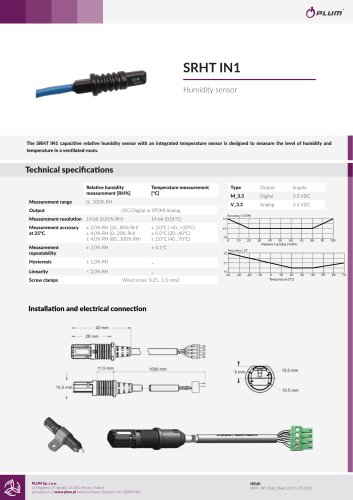

ecoKOM 200 Classic

2 Pages

-

850i v12

4 Pages

-

ecoMAX 200D

2 Pages

-

Pellets_Biomass_Coal

32 Pages

-

ecoMAX_800P

2 Pages

-

ecoTOUCH 800P

6 Pages

-

Research project

13 Pages

-

ecoNET 300

4 Pages

-

Solar systems

16 Pages

-

Fireplaces

20 Pages

-

Wood gasification

4 Pages

-

Pellet

6 Pages

-

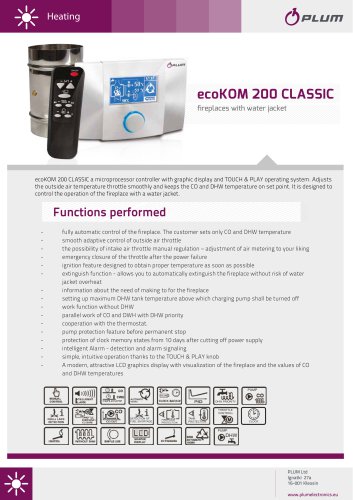

Folder heat pumps

4 Pages