Catalog excerpts

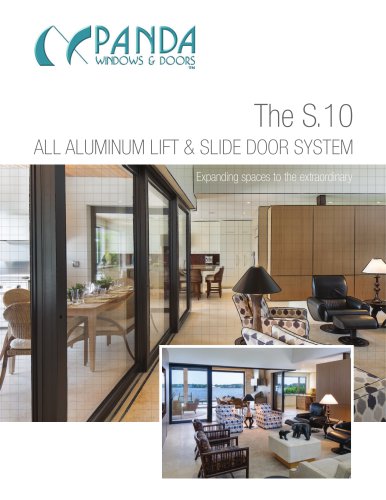

The S.10 ALL ALUMINUM LIFT & SLIDE DOOR SYSTEM Expanding spaces to the extraordinary

Open the catalog to page 1

Elevation View of a 4-panel Lift & Slide Door System - Stacked Configuration Panda’s Lift & Slide Door Systems have been designed to be the pinnacle of sliding door technology. Engineered to achieve superior performance, weather tightness and smooth operation in configurations where oversized panels are incorporated. This European inspired design provides minimal site-line interference opening up large expanses while bringing the outdoors in. They also offer versatility as interior doors in environments where sound control is important. The S.10 All Aluminum Lift & Slide Door System has been...

Open the catalog to page 2

Elevation View of a 4-panel Lift & Slide Door System - Pocketed Configuration FRAMED VIEWS Aluminum allows for larger sizes with huge glass expanses that not only accentuate the views of the surroundings but also welcome more natural daylight into interior spaces. With door panels that can reach up to 20′ tall, the S.10 Lift & Slide Door System creates a giant framed mural of the outdoors. The S.10 profiles are manufactured from 6063- T5 aluminum which provides superior strength and durability. Benefits Ÿ Greater access to natural daylighting improves well-being and allows for savings in...

Open the catalog to page 3

The Lift & Slide Advantage The Lift & Slide door system offers three significant advantages over conventional multi-slide doors. Smooth Operation The Lift & Slide door system runs on two wheel carriages engineered to provide maximum support and incredibly smooth movement. The wheel carriages that support the panels are comprised of synthetic nylon wheels with encased stainless steel ball bearings. Each wheel carriage can support up to 550 lbs which allows a 1,100 lbs panel to be supported by two multi wheel carriages. With just the push of a finger; heavy, oversized panels roll smoothly and...

Open the catalog to page 4

Functionality of a Lift & Slide Door System 2 4 1. Handle is in the closed and locked position. 2. Door System is securely sealed in the closed and locked position with the weather-stripping engaged in compression. The panels are pulled toward the jamb and lowered onto the track, engaging the dual weather gaskets at the top, bottom and sides. 3. A 180° turn of the door handle unlocks the door. 4. When the handle is rotated down 180°, a special hardware system that unlocks the door and lifts the panel off the track is activated. The door is lifted by about 3 16 taking the pressure off the...

Open the catalog to page 5

Panel Information 4" Rail Profile Number of Panels Ÿ Countless panel groups can be built. Panel Weight Ÿ Each panel weights approximately 7 to 8 lbs/sqft depending on overall panel size. Panel Size Ÿ Each panel is available in scalable sizes of up to 168″ and up to 240″ with a true divider. Ÿ Maximum width is 120″. Panel Construction Ÿ Panels are made of high quality 6063-T5 extruded aluminum with a profile thickness of 2 ¾″. Ÿ Maximum view and minimal obstruction with narrow 4″ stile and rail profiles. The S.10 System Have a question or want to reque

Open the catalog to page 6

Technical description MATERIALS Aluminum The S.10 frame extrusions are manufactured from 6063-T5 aluminum alloy for superior strength and durability. Glazing Ÿ Clear Low-E tempered-insulated glass is the standard. Ÿ Other glazing options at a thickness of up to 1 7/8″ may be used. S.10 corner detail Ÿ SDLs, TDLs and automated blinds may be integrated. OPERATING MECHANISM Ÿ The wheel carriages that support the panels are comprised of synthetic nylon wheels with encased stainless steel ball bearings and have a corrosion resistant treatment applied for high performance in coastal regions. Ÿ...

Open the catalog to page 7

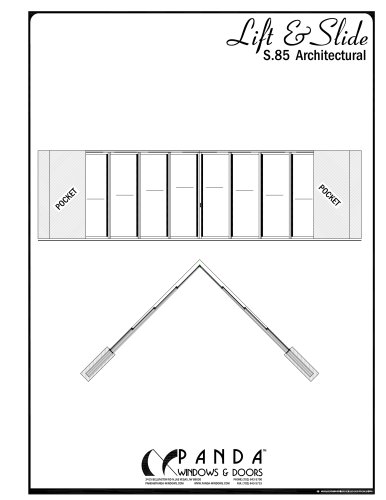

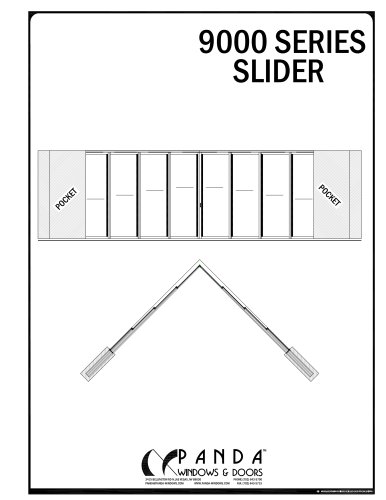

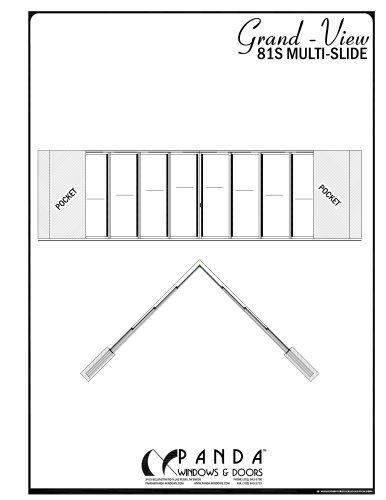

By custom building each door system in house with multiple panel, track types, angled panel connectors and radius curves, almost any size and shape of opening can be accommodated. STRAIGHT PANORAMIC With Pockets • System can pocket left or right. Without Pockets • System can stack left and/or right. The S.10 System Have a question or want to request a quote? Contact us

Open the catalog to page 8

Horizontal Section The S.10 System Have a question or want to request a quote? Contact us

Open the catalog to page 9

Vertical Section SURFACE DRAINAGE TRACK 5/16″ SURFACE TRACK RECESSED TRACK RECESSED DRAINAGE TRACK STANDARD RECESSED TRACK STANDARD RECESSED DRAINAGE TRACK The S.10 System Have a question or want to request a quote? Contact us

Open the catalog to page 10

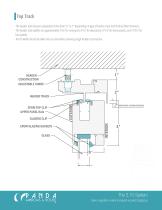

Top Track - The header track features adjustable shims from ½″ to 1″ depending on type of bottom track and finished floor thickness. - The header track widths are approximately 3 3 16″ for one panel, 6 7 16″ for two panels, 911 16″ for three panels, and 1315 16″ for four panels . - Trench width should be taken into account when planning rough header construction. The S.10 System Have a question or want to request a quo

Open the catalog to page 11

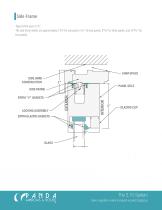

Side Frame - Typical shim space is ½″. - The side frame widths are approximately 3 3 16″ for one panel, 6 7 16″ for two panels, 911 16″ for three panels, and 13 15 16″ for four panels. The S.10 System Have a question or want to request a quote? Co

Open the catalog to page 12

The S.10 System Have a question or want to request a quote? Contact us

Open the catalog to page 13

The S.10 System Have a question or want to request a quote? Contact us

Open the catalog to page 14

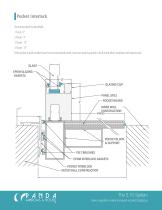

| Pocket Interlock Recommended Pocket Width 1 Track - 6" 2 Tracks - 9" 3 Tracks - 12" 4 Tracks - 15" If the pocket is built smaller than the recommended width, the inner wall may need to be framed after installation of bottom track. The S.10 System Have a question or want to request a quote? Contact us

Open the catalog to page 15

Corner Posts The S.10 System Have a question or want to request a quote? Contact us

Open the catalog to page 16

Bottom Tracks Standard Recessed Track Minimum Trench Depth: 2 ½” Recommended Trench Width 1 Track – 6 3 8″ 2 Tracks – 9 5 8″ 3 Tracks – 12 7 8″ 4 Tracks – 16 1 8″ - ADA Compliant. - Barefoot friendly passage. - Recessed into sub-floor to ensure the smoothest possible operation. - The finished floor is laid in between tracks leaving only a 3/16" rail exposed. The S.10 System Have a question or want to reque

Open the catalog to page 17All Panda Windows & Doors catalogs and technical brochures

Archived catalogs

-

ALUMINIUM WINDOWS

9 Pages

-

ALUMINIUM FRENCH / PIVOT DOOR

10 Pages

-

9000 SERIES

18 Pages

-

81 SERIES

17 Pages

-

Platinum

16 Pages

-

Lift & Slide alum. & wood

17 Pages

-

Lift & Slide all aluminium

17 Pages