Catalog excerpts

Technical Guide for Contractors PELLEMATIC® SmartXS

Open the catalog to page 1

Title: Technical Guide PELLEMATIC® SmartXS Version valid from: 11/2018 Approved: Wohlinger Christian

Open the catalog to page 2

Technical Guide PELLEMATIC® S

Open the catalog to page 3

4 Pellets — a fuel with strict quality requirements 1 Pellets — a fuel with strict quality requirements The raw material for pellets is wood. They are produced from saw and planer shavings, by-products of the sawmill industry. Due to their high energy content and their shape, pellets are easy to transport and ideally suited to fully automatic heating operation. The high energy content is achieved by enormous compression of the shavings during pellet production. Materials with a high starch content from the food processing industry are used as a compression additive (e. g. corn starch)....

Open the catalog to page 4

Product description Pellematic SmartXS 5 FULL COMFORT PELLETS-SOLAR-HYBRID HEATING The Pellematic Smart XS uniquely combines a pellet condensing boiler including domestic hot water heating (approx. 230 litres at 40° water temperature) and heating circuit assembly with a solar heating system. The entire unit can be installed on only 0.9 m2 of floorspace and flush with the wall on two sides. The Pellematic Smart XS is equipped with an integral solar heating system. Solar collectors make your heating system even more ecological and also save you money. The controller ensures that solar energy...

Open the catalog to page 5

6 Overview Pellematic Smart XS

Open the catalog to page 6

Benefits for consumers and heating engineers 7 Benefits for consumers and heating engineers 7 Solar heating (optional) Hot water generation Heating circuit Technical Guide PELLEMATIC® SmartXS

Open the catalog to page 7

2.3 Combustion technology Fuel supply The hopper is loaded by means of a vacuum turbine. A metering auger located below the hopper conveys the pellets to the burn-back-proof ball lock.

Open the catalog to page 8

Combustion technology Air intake / combustion gas route The variable speed, induced draft fan generates an output-dependent negative draft in the boiler and draws combustion air into the air chamber. Here this air is divided into primary air and secondary air. The primary air flows through the burner plate to the fuel, while the secondary air flows through the burner auger tube to the end where it is mixed with the combustion gases. The hot air heated for the ignition process is also supplied from the air chamber, while the secondary air supply likewise takes this over after the ignition...

Open the catalog to page 9

10 Special planning information 3 Special planning information 3.1 Condensing technology 3.1.1 General Condensing systems are capable of harnessing the latent (hidden) heat contained in the flue gas. This heat is utilised by cooling down the flue gas to the point where the water vapour, which is always present in flue gas, condenses (liquefies), at the same time releasing the inherent energy (the latent heat of condensation). This is fed back into the system. Condensing technology means additional heat gain from flue gases. , pelletsfuel oil Value of air ratio The basic requirement for the...

Open the catalog to page 10

Condensate - Connection to the discharge pipe 11 3.1.2 Condensate - Connection to the discharge pipe In condensing operation (gross calorific value mode), condensate is produced, which must be discharged into the drainage system. Discharging the condensate into the drainage system is possible without special permission in almost every European country. Neutralisation of the condensate is not necessary. In condensing mode, a condensate volume of approx. 0.35 l/kg of fuel is generated with pellets. Assuming an annual consumption of approx. 4 tonnes of pellets, this results in a condensate...

Open the catalog to page 11

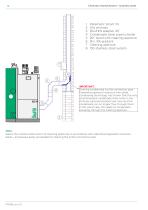

12 Balanced flue operation The Pellematic Smart XS benotigt requires combustion air.. Combustion air can be supplied directly from the room (figure a) (open flue) via traditional ventilation apertures (2). Or in room-sealed (balanced flue) operation (figure b). Air must be supplied through a system of pipes directly from the open air or via the connection to a separate ventilation shaft (2) located in the chimney. Room-sealed (pipe-in-pipe) balanced flue systems are not permitted! Caution: • On no account may combustion air be supplied via the drainage system! • The diameter of the air...

Open the catalog to page 12

Connection pipe to chimney 3.1.4 Connection pipe to chimney The connection pipe must satisfy the following criteria: • Made off stainless steel • moisture-resistant (condensate-proof) • min. 20 Pascal overpressure-tight • certification (CE or ÜA mark) The flue must be equipped with a cleaning aperture and a flue gas test port. Ensure that access is as easy as possible. The diameter of the flue gas system must be selected based on a chimney calculation as per EN 13384-1 and must be at least 130 mm. The flue pipe must be mounted at an incline. Avoid horizontal lines! It must be no longer than...

Open the catalog to page 13

Chimney refurbishment – stainless steel Pellematic Smart XS Old chimney ÖkoFEN adapter 45˚ Condensate drain pipe to boiler 90˚ bend with cleaning aperture Min. 5% gradient Cleaning aperture 130 stainless steel system Draining condensate via the connection pipe. Experience gained in practice with pellet condensing technology has shown that the very small standard condensate drain holes in the chimney become blocked over time and the condensate can no longer flow through them. In the worst case, this leads to condensate escaping through the cleaning aperture. Note: Select the number and...

Open the catalog to page 14

Chimney systems 3.1.6 Chimney systems The dimensions and design of the chimney are very important. The chimney must ensure a sufficient negative draft in all operating states of the boiler in order to discharge the flue gases reliably. Low flue gas temperatures result in the formation of condensation. You must therefore use moisture-resistant chimneys made from ceramic or stainless steel. Select the diameter of the chimney on the basis of a chimney calculation in accordance with EN 13384. Please contact your chimney manufacturer and/or chimney sweep regarding this. The volume of flue gases...

Open the catalog to page 15All ÖkoFEN catalogs and technical brochures

-

Technical data PELLEMATIC®

6 Pages

-

PELLEMATIC® PE(S) 10 — 56 kW

4 Pages

-

Pellematic Compact

4 Pages

-

PELLEMATIC PE(S) 10 — 56 kW

5 Pages

-

PELLEMATIC Smart 4 — 14 kW

9 Pages