Catalog excerpts

NOE-Schaltechnik Product overview

Open the catalog to page 1

Over fifty years of formwork experience Up to the start of the 1950s, formwork systems were largely unknown. Instead, concrete was cast in forms that were individually made for each project out of squared timber and boards. As these forms could usually be used only once, this approach was very time consuming and costly. Against this background, Georg MeyerKeller developed a universal steel formwork system with components which could be used many times and thus considerably simplified the construction process. The patent for this design was granted in 1952 and established Georg Meyer-Keller as...

Open the catalog to page 2

n5e Use cost-effective and efficient NOE formwork systems to your advantage. Figure V: Schematic diagram of an earlier typical concrete form. Figure 2: Building a concrete form in the fifties. Figure 3: The Weststadt School in Goppingen was one of the first sites where systemised concrete formwork was used: universal steel formwork. Figure: 4: This example of modern formwork technology is NOEtop frame formwork with integrated bracing. Shown here used for the construction of a bulk goods store in Europort Rotterdam. Figure 5: Another example of modern formwork technology:NOEtec...

Open the catalog to page 3

NOE®top Forward-looking formwork concept NOEtop is a synthesis of frame and beam formwork. This makes it a multifunctional system that opens new areas of use with opportunities way in excess of those offered by ordinary frame formwork. With an allowable concrete pressure of 88 kN/m2, NOEtop is suitable for use on all typical construction projects. To make your work easier, NOE also stocks a wide range of innovative additional components. The latest example: NOEtop EinsA - the time- and cost-saving one-sided tie rod system from NOE. NOEtop ■ Extends the range of application of frame...

Open the catalog to page 4

■ Allowable concrete pressure up to NOEtop stripping corner 60 kN/m2 Integrated into the NOEtop formwork system: The NOEtop one-sided tie rod system. NOEtop EinsA used in the NOEtop formwork system saves time and costs. All NOEtop large area panels can also be used with the one-sided tie rod system. Simple clamping mechanism ■ No sleeve required thanks to conical tie rod ■ Substantial time savings compared to conventional tie rod arrangements Standard panels can be tied from one side using tie rod hole bridges Conical tie rod sealed with a cost-effective rubber seal For lift shafts,...

Open the catalog to page 5

NOE®top R Free choice of facing NOEtop R greatly increases the scope of use of the NOEtop formwork system. Top hat profiles with plastic strips are integrated into the frame panels with integrated bracing members. This allows any type of formwork facing to be attached - irrespective of the panel arrangement. Your advantage: NOEtop R is based on the proven NOEtop panel system, i.e. can be used with the same accessories as the NOEtop formwork system. Use the advantages of the NOEtop R to your advantage when constructing fair-faced concrete surfaces.

Open the catalog to page 6

Safety built-in NOEtop S is designed for use in countries with particularly high site safety standards. Working platforms with all-round safety rails, ladder access and integrated stabilizers are attached directly to NOEtop large area panels and are supplied to site ready for immediate use. Fold out the working platform and align the stabilizers – and the NOEtop S ready for use. It requires only to be folded up before being moved to the next position. Dismantling is not required. NOEtop S meets the particularly high requirements applicable in France. Use the advantages that this all-round...

Open the catalog to page 7

The NOEtop FS allows columns with cross sections from 200 to 600 mm to be concreted without tie rods. The cross section dimensions are adjustable in 50 mm increments. Available in two versions: with steel facing or as a supporting frame for any type of 21 mm thick formwork facing. Installation and removal is done in one piece, i.e. the formwork does not have to be assembled or disassembled. Repositioning can also be done in one piece. Workplace safety is ensured in the form of working platforms and ladder access including a ladder safety cage as a matter of course. Concreting of tie rod...

Open the catalog to page 8

An impressive circular formwork system for curved, vertical structures with radii from 2750 mm. Your advantage: The initial, first-use radius is set at the factory so that the formwork can be delivered to your site ready for immediate use. Setting to other radii for later uses can be done quickly and easily. NOE R 110 is available for radii from 1100 mm. Use the advantages of NOE circular formwork and NOE’s full-service packag

Open the catalog to page 9

NOE®alu L The ideal manual formwork NOEalu L is the innovative lightweight member of the NOE wall formwork family. In developing this product, NOE's engineers concentrated on creating a system that could be moved around using muscle power only and yet be capable of withstanding the stress and strain of everyday life on site. NOEalu L is designed for formwork pressures up to 60 kN/m2. If you have larger areas of formwork to construct, you can make very effective use of NOEalu XL with its form face areas up to 5.50 m2. NOEalu L excels in particular through: ■ A low self-weight ■ A robust...

Open the catalog to page 10

High performance steel formwork = NOE®mega Developed for markets with particular demands for ■ High concrete pressures and modern concrete technology ■ Workplace safety High number of reuses and durability Jointless concrete surfaces NOEmega impresses through its ■ Allowable concrete pressure up to 100 kN/m2 ■ Low transport and storage height 5 mm thick special sheet metal form, pickled and oiled NOEtop edge profiles for positive connections Delivered to site ready for use Safety features and bracing integrated into all formwork elements User-friendly design See for yourself the efficiency...

Open the catalog to page 11

NOE® HBF support bracket Modular single-sided The new NOE HBF support bracket is a newly developed modular support bracket for single-sided forms up to 10.00 m formwork height. For formwork heights up to 10.00 m Modular design Only 4 system components Simple installation Simple to extend Use the advantages of the modular ar NOE HBF support bracket.

Open the catalog to page 12All NOE PLAST catalogs and technical brochures

-

569315 "Basalt"

1 Pages

-

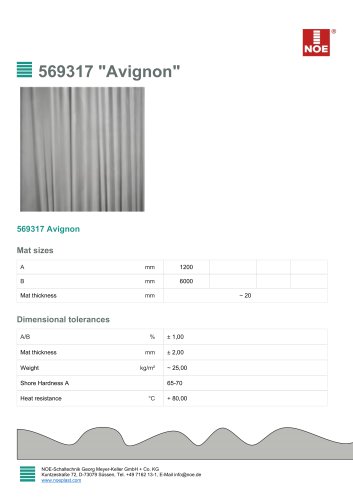

569317 "Avignon"

1 Pages