Catalog excerpts

How the global mining industry controls its costs and improves environmental performance The daily mining rates, scale of single-site operations, and costs associated with mining increase every year. Advances in extraction technologies have greatly increased recovery rates from ore bodies. Mine designs previously thought to be too big to be possible are achieved every year or two so that an average mine today is significantly larger than an average mine just 10 years ago. To construct on this scale, which is often necessitated by marketplace price points and competition for investor support,...

Open the catalog to page 3

Without question, heap leach has become an enormous driver to the growth of mining operations around the world. Several decades ago, only about 3% of copper and gold supplies were produced through heap leaching. Today, the volume is surpassing 30% annually. Valuable chalcopyrite copper, previously not considered economical in heap leach development, is now heap leached, as is nickel laterite, uranium, and even rare earths. The growth of heap leaching is heavily tied to the massive scale on which mines are being built, with some sites requiring huge investments. Heap leach stacks can near...

Open the catalog to page 4

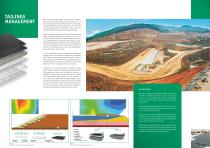

TAILINGS MANAGEMENT When an ore's valuable deposit, such as copper or gold, is extracted, what remains of the ore is waste. Often, it is a high percentage of the ore handled at the mine. Potentially contaminated from the extraction process or containing environmentally harmful components, tailings must be isolated to prevent long-term environmental damage. Design engineers working on mines must allot significant space for proper containment of tailings. All or much of this area must be sealed with an impermeable geosynthetic (e.g., geomembrane) or composite lining system (e.g.,...

Open the catalog to page 5

EVAPORATION PONDS Evaporation is used in a variety of mining operations to separate valuable materials from water or brines. Diverse salts, for example, can be extracted by evaporation. Lithium-rich brines may be concentrated through evaporation. These materials, when harvested from solar ponds, are then able to be refined into items used across a wide variety of industries, in agriculture, in food products, etc. For sites where remediation or isolation of a contaminant is a goal, the act of evaporation in an engineered pond can also be an effective solution, especially in the case...

Open the catalog to page 6

MINE CLOSURE The life of a mine varies wildly. It could be shuttered after 6 months due to a swift decline in market prices for metals. That same site might be reopened 10 years later when a rise in prices makes the site economically viable again. A mine might operate for 20 years with little interruption, but over the course of those years change three times the type of valuable ore it processes. Ownership of the site can transfer multiple times. The development of new extraction technologies might cause some long-closed facilities to be reopened so that ore can be further exploited....

Open the catalog to page 7

ACCESS ROADS AND OTHER GEOTECHNICAL STRUCTURES Mines are, in many respects, small cities. They require roads, water, power, waste management, food, safety, housing, etc. Access roads are especially integral to a mine’s viability. Ore must move around and away from the site. Shipments of supplies must not be impaired. Site access delays of a single day can cost a lot. Extended interruption in access to the site can threaten the mine’s continued operation, as investors and mine owners might no longer consider it economically viable. The massive vehicles used in mining today require extremely...

Open the catalog to page 8

QUALITY CONTROL The performance characteristics of a geosynthetic are determined by components such as its polymer, additive package, fibres, and other raw materials. These components give products their chemical compatibility, UV resistance, durability in exposed or buried conditions, biological resistance, elongation, and other characteristics needed to provide the proper service life and strength in an application. The quality of these raw materials, the manner in which they are handled, and the technology used to manufacture the final product further influence material...

Open the catalog to page 9

NAUE is an EN ISO 9001-certified company. The company’s comprehensive range of geosynthetic products serves the diverse geotechnical needs of the mining industry, providing solutions for containment of leached material and tailings, on-site water storage, stormwater management, erosion control, isolation of contaminants, soil structure reinforcement, access road stability, evaporation ponds, and much more. These materials are engineered for long-term performance, delivering economy and environmental effectiveness to mining operations around the world. Key products include: • Bentofix®...

Open the catalog to page 10

NAUE GmbH & Co.KG Gewerbestrasse 2 32339 Espelkamp-Fiestel Germany E-Mail info@naue.com Internet www.naue.com Memberships of the NAUE Group Approvals for the NAUE Group \ , Bentofix®, Carbofol®, Combigrid®, Secudrain®, Secugrid®, Secumat®, Secutex® and Terrafix® are registered trademarks of NAUE GmbH & Co. KG in various countries. The information contained herein is, to the best of our knowledge, true and accurate. There is no implied or expressed warranty. © 2016 by NAUE GmbH & Co. KG, Espelkamp-Fiestel, Germany • All rights reserved. • Status 25.11.2016

Open the catalog to page 11All NAUE catalogs and technical brochures

-

Secugrid® HS

4 Pages

-

Combigrid®

4 Pages

-

Secugrid® PET/PP

4 Pages

-

CARBOFOL® geomembranes

4 Pages

-

geotextile introduction

4 Pages

-

SECUTEX® Soft Rock

4 Pages

-

BENTOFIX® X

4 Pages

-

BENTOFIX®

4 Pages

-

LANDFILL Engineering

13 Pages

-

Civil engineering

32 Pages

-

Tunnel construction

16 Pages

-

NAUE_Renewable_wind_energy

8 Pages

-

Secugrid® PDF

3 Pages

-

Secudrain® PDF

2 Pages

-

Combigrid® PDF

2 Pages

-

Bentofix® PDF

3 Pages

-

Carbofol® PDF

3 Pages