Catalog excerpts

LANDFILL Engineering

Open the catalog to page 1

LANDFILL ENGINEERING

Open the catalog to page 2

Fifty years ago, the waste stream was quite different. Organ ics were mostly recycled, composted or incinerated. Pack aging was made of wood or paper. Plastics were still largely unknown. At that time around the world as well as in Germany—where geosynthetics from NAUE were born—waste legislation had not been established, so disposal practices were determined by basic administrative bodies. Municipalities were concerned more with the appearance of appropriate practice. The 1960s’ industrial boom, however, created an unprecedent increase in the volume of waste needing to be managed. The...

Open the catalog to page 3

Regulatory agencies around the world have long accepted geosynthetics as an alternative design solution or have outright required their use in certain applications. The waste management sector has benefited more than any other sectors, through the requirement to use geosynthetics in municipal solid waste containment and closure systems. Europe, Germany and the United States provide exemplary cases for the incorporation of geosynthetics into environmental regulations to prevent or reduce as much as possible, any negative impact from landfilling on surface water, groundwater, soil, air or...

Open the catalog to page 4

Sealing Acting as liquid and gas barriers, geomembranes have become a fundamental component in landfill engineering as well as in civil engineering, due to the heightened need for groundwater protection. High density polyethylene (HDPE) geomembranes, specifically those with a certification by government regulators and thicknesses of more than 1.5mm, are most commonly used. Personnel from those companies that have been approv ed by the certifying agency, are employed to both deploy and weld the geomembranes where an area needs to be sealed. For sealing purposes HDPE geomembranes and...

Open the catalog to page 5

Landfill base lining systems provide permanent protection of soils and groundwater from the pollutants in a waste mass. Lining system requirements are often specified in national regulations and geosynthetics have become common components of these systems. Geosynthetics fulfill the stringent containment parameters of landfill liner regulations. Geosynthetics provide an efficient, significantly effective and durable barrier for long-term environmental protection. But achieving this effectiveness requires proper design, specification and installation of the geosynthetic system. To remove...

Open the catalog to page 6

INTERMEDIATE SYSTEM An intermediate seal separates adjacent landfill cells. It is used when the landfill, to be abutted, does not have a sufficient seal to serve as base or an appropriate fill due to differing landfill classifications between the neighboring cells. Thus, the intermediate seal can serve upper or closure layer of one cell and simultaneously, the base seal for the next. Intermediate seals are not clearly described in most landfill regulations, so permitting authorities often call for typical base liner requirements. Historically, zoning decisions in municipal solid waste...

Open the catalog to page 7

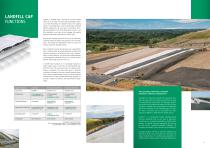

Upon closure, landfills must be capped. The specific requirements for permanent sealing systems for Class I (inert waste), II (municipal solid, non-hazardous waste) and III (hazardous waste) landfills are typically outlined in the national regulations. High safety requirements are imposed on all components of the sealing system. Each geosynthetic should typically be approved by the federal authority or a national agency. Part of the approval process should show, in testing data, that sealing system components can provide at least 100 years of service life. Additionally, interest in...

Open the catalog to page 8

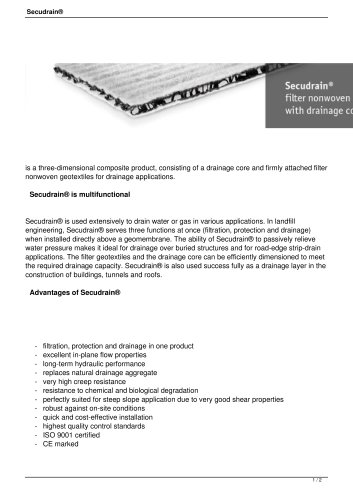

Typically, a drainage layer is required for all major landfill classes (I, II, and III). This layer sheds precipitation directly, to avoid the buildup of a hydraulic head on the capping system. The drainage layer must be permanently protected against clogging from the cover layer's soil particles. Drainage geocomposites with three-dimensional matrices and filter geotextile cover layers control seepage and properly designed fulfil design requirements in landfill caps. Geosynthetic drainage systems of this nature are sufficiently protected against the damage risk posed by cover soil...

Open the catalog to page 9

RECLAMATION AND REDEVELOPMENT OF CONTAMINATED SITES Former landfills and contaminated sites are often capped and remediated. These engineering works may also include beneficial reuse of the sites. On-site contaminants and the uneven settlement in the ground above these former waste cells present a number of geotechnical challenges. As such, capping measures generally are selected for their ability to isolate and contain contaminants. Closure measures may also be evaluated on their ability to increase the site’s load bearing capacity for safer reuse. Capping systems for former waste cells...

Open the catalog to page 10

QUALITY CONTROL The performance characteristics of a geosynthetic are determined by components such as its polymer, additive package, fibres and other raw materials. These components give products their chemical compatibility, UV resistance, durability in exposed or buried conditions, biological resistance, elongation and other characteristics needed to provide the proper service life and strength in an application. The quality of these raw materials, the manner in which they are handled and the technology used to manufacture the final product further influence material performance. Here,...

Open the catalog to page 11

NAUE is an EN ISO 9001-certified company. The company's comprehensive range of geosynthetic products serves the diverse geotechnical needs of the landfill industry, providing solutions for containment of waste material landfill caps and closures, intermediate base sealing liners, onsite water storage, stormwater management, soil structure reinforcement, access road stability and much more. These materials are engineered for long-term performance, delivering economy and environmental effectiveness to landfill operations around the world. Key products include: • Bentofix® geosynthetic clay...

Open the catalog to page 12All NAUE catalogs and technical brochures

-

Secugrid® HS

4 Pages

-

Combigrid®

4 Pages

-

Secugrid® PET/PP

4 Pages

-

CARBOFOL® geomembranes

4 Pages

-

geotextile introduction

4 Pages

-

SECUTEX® Soft Rock

4 Pages

-

MINING and GEOSYNTHETICS

11 Pages

-

BENTOFIX® X

4 Pages

-

BENTOFIX®

4 Pages

-

Civil engineering

32 Pages

-

Tunnel construction

16 Pages

-

NAUE_Renewable_wind_energy

8 Pages

-

Secugrid® PDF

3 Pages

-

Secudrain® PDF

2 Pages

-

Combigrid® PDF

2 Pages

-

Bentofix® PDF

3 Pages

-

Carbofol® PDF

3 Pages