Catalog excerpts

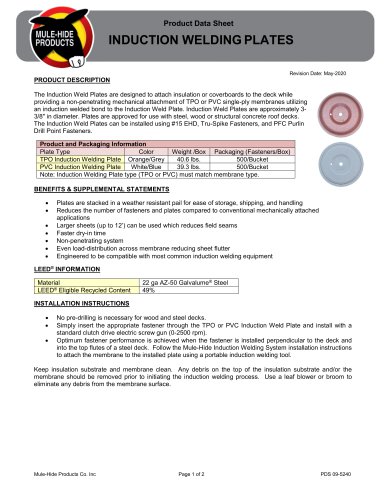

Product Data Sheet INDUCTION WELDING PLATES Revision Date: May-2020 PRODUCT DESCRIPTION The Induction Weld Plates are designed to attach insulation or coverboards to the deck while providing a non-penetrating mechanical attachment of TPO or PVC single-ply membranes utilizing an induction welded bond to the Induction Weld Plate. Induction Weld Plates are approximately 33/8" in diameter. Plates are approved for use with steel, wood or structural concrete roof decks. The Induction Weld Plates can be installed using #15 EHD, Tru-Spike Fasteners, and PFC Purlin Drill Point Fasteners. Product and Packaging Information Plate Type Color Weight /Box Packaging (Fasteners/Box) TPO Induction Welding Plate Orange/Grey 40.6 lbs. 500/Bucket PVC Induction Welding Plate White/Blue 39.3 lbs. 500/Bucket Note: Induction Welding Plate type (TPO or PVC) must match membrane type. BENEFITS & SUPPLEMENTAL STATEMENTS • • • • • • • Plates are stacked in a weather resistant pail for ease of storage, shipping, and handling Reduces the number of fasteners and plates compared to conventional mechanically attached applications Larger sheets (up to 12’) can be used which reduces field seams Faster dry-in time Non-penetrating system Even load-distribution across membrane reducing sheet flutter Engineered to be compatible with most common induction welding equipment LEED® INFORMATION Material LEED® Eligible Recycled Content INSTALLATION INSTRUCTIONS • • • No pre-drilling is necessary for wood and steel decks. Simply insert the appropriate fastener through the TPO or PVC Induction Weld Plate and install with a standard clutch drive electric screw gun (0-2500 rpm). Optimum fastener performance is achieved when the fastener is installed perpendicular to the deck and into the top flutes of a steel deck. Follow the Mule-Hide Induction Welding System installation instructions to attach the membrane to the installed plate using a portable induction welding tool. Keep insulation substrate and membrane clean. Any debris on the top of the insulation substrate and/or the membrane should be removed prior to initiating the induction welding process. Use a leaf blower or broom to eliminate any debris from the membrane surface.

Open the catalog to page 1

Product Data Sheet TPO and PVC Induction Welding Plates Properly installed plate and fastener Correctly installed plate and fastener (straight edge for reference only) Incorrectly installed Plate (fastener overdriven distorting the plate downward) Review Mule-Hide specifications and details for complete installation information. PRECAUTIONS • • • Eye protection is recommended during installation Use care to avoid over-torquing the fastener Do no expose plates to UV for extended periods PROTECTION & SAFETY Mule-Hide maintains Safety Data Sheets on all of its non-exempt products. Safety Data...

Open the catalog to page 2All MULEHIDE catalogs and technical brochures

-

Asphalt Cements

6 Pages

-

EPDM Systems Contractor

6 Pages

-

EPDM Systems

6 Pages

-

Maintenance Repair

6 Pages

-

Single Ply Roofing Accessories

44 Pages

-

PVC Architect Brochure

4 Pages

-

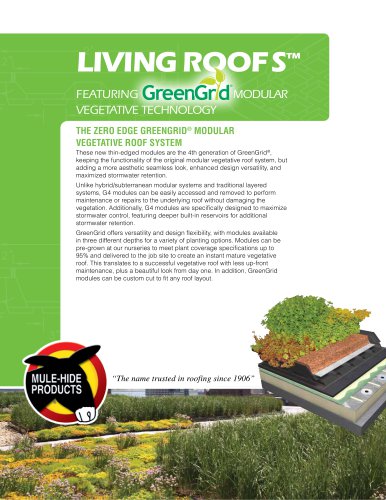

Living_Roof_Brochure_LR

8 Pages