Catalog excerpts

Product Data Sheet DESCRIPTION Helix® Max Low-Rise Adhesive-5-Gallon Jug (“Helix Max Adhesive”) is a low-rise, VOC- free, construction-grade, two- component polyurethane adhesive that is designed to bond Mule-Hide's insulations and Fleece Back (TPO, PVC or PVC KEE) membranes to a variety of substrates. FM Approvals have been achieved over a variety of deck types and substrates. PACKAGING • Superior wind uplift resistance / FM approved • Can be used for most re-roofing projects • Quick, quiet, low-odor application • Elongation of up to 150% • Eliminates the need to pre-drill into concrete and gypsum decks • Added puncture resistance of 33-50% compared to standard Helix Adhesive (with full spray application) • Jug design provides increased moisture resistance and protection against moisture contamination • Adhesive visibility - Provides a visible cue for container change-out and in case of an off-ration mix • Easy-load handles - Top- and side-load handles allow jugs to be easily loaded on dispensing equipment • Easy-flow vent - Provides even distribution of adhesive to the static mixing tip • Increased packaging durability APPLICATION General Preparation (Helix® Max Low-Rise Adhesive-5-Gallon Jugs require a low-pressure urethane adhesive dispensing machine for bead application, and high pressure equipment for full spray application) 1. The surface to which adhesive is applied shall be dry, clean, free of fins, protrusions, sharp edges, loose and foreign materials, oil, and grease. Depressions greater than 1/4" shall be filled with Helix Max Adhesive or other approved patching material. All sharp projections shall be removed. Previously unexposed (shiny) asphalt must be primed with AeroWeb. 2. Seal gaps between the wall/penetration and concrete deck with Mule-Hide F5 Air & Vapor Barrier or other suitable material to avoid condensation issues and positive pressure from air infiltration. 3. Apply Helix Max Adhesive when the substrate and ambient temperatures are 25°F (-4°C) or above when spraying or extruding with heated or non-heated equipment. Dispense the adhesive between 300-800 psi depending on the equipment used. Consult Mule-Hide Technical Department for more details. 4. Fibrous cement decks must be investigated for their ability to retain liquid adhesive, as some types of fibrous cement may allow liquid adhesive to flow through the deck.

Open the catalog to page 1

Product Data Sheet 1. Apply Helix Max Adhesive to the substrate. Allow the material to transition from a dark blue to a light blue colored foam. a. For spray applications, spray adhesive to obtain full (100%) coverage (approx. 1/8" to 1/4" thick after foaming). b. For bead applications, apply adhesive at 4", 6", or 12" on center with a minimum 1/2" wet bead. For steel decks, extrusion of Helix Max must run parallel with and be on top of the steel deck flutes. 2. Factory Mutual bead spacing guidelines in the perimeter and corner may differ from the table above. Beads at 12" OC are not...

Open the catalog to page 2

Product Data Sheet *Bead spacing guidelines for 10, or 15-year, 55-mph warranties are listed below. Contact Mule-Hide's Technical Department regarding bead spacing for 20 and 30-year warranties and/or warranties with wind speeds higher than 55 mph. Fleece Back Installation Slide-in Method: 1. Unroll Fleece Back sheet and position. Fold the sheet back in half lengthwise (end-to-end). 2. Spray-apply or extrude Helix Max Adhesive to the substrate. a. For full spray application, spray adhesive to obtain full coverage (approx. 1/8" to 1/4" thick after foaming). Ensure end laps are protected from...

Open the catalog to page 3

Product Data Sheet pressure build-up in container. • Pressure should never be applied as a means of transferring liquid. If the jug container will not be completely emptied, it is imperative to prevent atmospheric moisture contamination of the remaining diisocyanate. Even a small amount of contamination by water or other foreign substance could result in excess pressure and catastrophic failure of the jug container. Do not reseal a drum if contamination is suspected. If product contamination occurs by water or other foreign substance and excess jug pressure occurs, if possible do not move...

Open the catalog to page 4All MULEHIDE catalogs and technical brochures

-

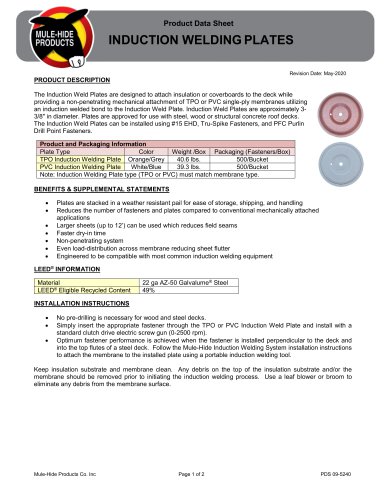

INDUCTION WELDING PLATES

2 Pages

-

Asphalt Cements

6 Pages

-

EPDM Systems Contractor

6 Pages

-

EPDM Systems

6 Pages

-

Maintenance Repair

6 Pages

-

Single Ply Roofing Accessories

44 Pages

-

PVC Architect Brochure

4 Pages

-

Living_Roof_Brochure_LR

8 Pages