Catalog excerpts

Product Data Sheet HELIX® MAX LOW-RISE ADHESIVE-DUAL TANK Rev. 3-2021 Helix® Max Low-Rise Adhesive-Dual Tank (“Helix Max Adhesive”) is a low-rise, construction-grade, two-component polyurethane adhesive that is designed to bond Mule-Hide's insulations and Fleece Back (TPO, PVC or PVC KEE) membranes to a variety of substrates. FM and other agency approvals have been achieved over a variety of deck types and substrates. Self-contained tank set (A & B Components) includes guns, spray nozzles, 14” extension nozzle, and hoses in the A-side box. • HFO Blowing agent - Green alternative offering low GWP's and Zero ODP's - New tips provide improved splatter pattern with more uniform application - Improved coverage rates - Improved cell structure and product rise - Improved string time • Superior wind uplift resistance / FM approved • Can be used for most re-roofing projects • Quick, quiet, low-odor application • Elongation of up to 150% • Eliminates the need to pre-drill into concrete and gypsum decks • Reduces labor by eliminating equipment maintenance and breakdowns • VOC-free, self-contained system General Preparation 1. The surface to which adhesive is applied shall be dry, clean, free of fins, protrusions, sharp edges, loose and foreign materials, oil, and grease. Depressions greater than 1/4" shall be filled with Helix Max Adhesive or other approved patching material. All sharp projections shall be removed. Previously unexposed (shiny) asphalt must be primed with AeroWeb. 2. Seal gaps between the wall/penetration and concrete deck with Mule-Hide F5 Air & Vapor Barrier or other suitable material to avoid condensation issues and positive pressure from air infiltration. 3. Apply Helix Max Adhesive when the substrate and ambient temperatures are 25°F (-4°C) or above. Consult Mule-Hide Technical Department for more details. 4. Fibrous cement decks must be investigated for their ability to retain liquid adhesive, as some types of fibrous cement may allow liquid adhesive to flow through the deck. 5. Static mixing tips for Helix Adhesive (or other manufacturers) and Helix Max Adhesive are not interchangeable, only use the nozzles provided in the packaging for application.

Open the catalog to page 1

Product Data Sheet Dual Tank Use Instructions Note: When spraying the dispensing unit for the first time, or when starting a new kit, Mule-Hide recommends that users trigger the gun only a quarter to halfway open until the desired output and spray pattern is achieved. This allows complete control of the flow rate and spray pattern that best fits the application. 1. Spray gloves, long sleeves, and protective glasses should be worn during setup and dispensing. 2. For best results, use when material is between 70°F and 90°F. 3. When applying Helix Max in colder temperatures the use of heating...

Open the catalog to page 2

Product Data Sheet Helix Max Low-Rise Adhesive-Dual Tank attach the 14" extension nozzle to the gun nozzle tip. Splatter application can be achieved by triggering the gun from a distance of 2'-3' off the deck. Adhesive should be dispersed using a horizontal back and forth motion, achieving 50% coverage of the substrate at 3.75 lbs/sq. 11. Once the trigger is released, it MUST BE REACTIVATED WITHIN 15 SECONDS or a new nozzle must be installed. Failure to do this could result in chemical leakage, spills, or splashes which can ruin the dispensing unit and/or hoses. 12. After releasing the...

Open the catalog to page 3

Product Data Sheet 1. Dispense Helix Max Adhesive in beads at the appropriate coverage rate. For steel decks, beads of adhesive must run parallel with, and be on top of, all of the flutes. 2. Place insulation boards (maximum 4' x 4'), or cover boards (DensDeck Prime or Securock may be 4' x 8') into adhesive after allowing it to rise and develop “string/body”. 3. String time will vary based on environmental conditions like temperature and humidity. Do not allow the adhesive to over-cure (lose tack) prior to setting insulation boards. 4. Designate one person to walk boards into place and then...

Open the catalog to page 4

Product Data Sheet vapors with prefilters and solvent- resistant cartridges or supplied airline respirators while spraying. Proper safety training is essential for all persons involved in the installation process. If vapor is inhaled, remove to fresh air and administer oxygen if breathing is difficult. Consult a physician immediately • Avoid contact with eyes. Safety glasses or goggles are required. If Helix Max Adhesive is splashed in eyes, immediately flush eyes with plenty of clean water for at least 15 minutes. Contact a physician immediately. • Avoid contact with skin. Wear...

Open the catalog to page 5All MULEHIDE catalogs and technical brochures

-

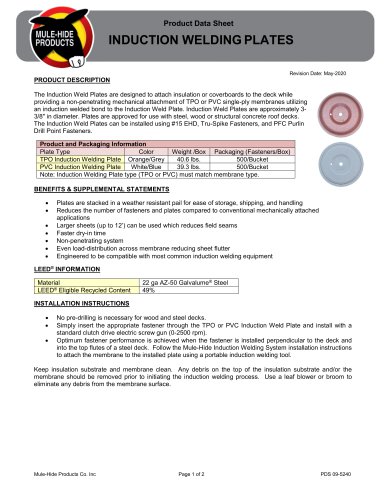

INDUCTION WELDING PLATES

2 Pages

-

Asphalt Cements

6 Pages

-

EPDM Systems Contractor

6 Pages

-

EPDM Systems

6 Pages

-

Maintenance Repair

6 Pages

-

Single Ply Roofing Accessories

44 Pages

-

PVC Architect Brochure

4 Pages

-

Living_Roof_Brochure_LR

8 Pages