Catalog excerpts

Elastomeric Acrylic Coatings APPLICATION HANDBOOK

Open the catalog to page 1

IMPORTANT NOTES (Details and Information Subject to Change) When applying coatings over an existing roof under warranty, the building owner should check with the existing roof system manufacturer, as this coating application may void a warranty. In all cases, the existing roof system must be in sound condition prior to coating. Mule-Hide is not responsible for any defect(s) in the existing roof system. Mule-Hide requires proper surface preparation of the existing roof system. Blisters, splits, and other surface defects, should be repaired in accordance with the published NRCA Repair Manual...

Open the catalog to page 2

IMPORTANT NOTES GENERAL INFORMATION About Mule-Hide Safety First Material Storage General Precautions General Tools & Equipment Needed 9 Recommended Airless Spray Equipment Guide 9-10 Types of Warranties Available 12 Warranty Coverage Application Rate Guidelines 12-23 Warranty Program Disclaimer 23 Pre-Job Preparation Guidelines 24-33 Inspecting the Existing Roof to be Coated 25-28 Adhesion Test Instructions 29-30 Percent Solids - Wet Film - Dry Film Chart 31 Product Description, Basic Uses, Typical Physical Properties and Cured Film Properties A-125 METAL ROOF PRIMER A-151 EPDM Resurface...

Open the catalog to page 3

Finish Coats —continued A-320 FINISH (For over asphaltic substrates and areas of light periodic 44-45 ponded water) A-400-W MASONRY WALL COATING 46-47 Liqui-Thix® (Turns A-300 into A-200) 48 General Application Guidelines 51-53 Surface Preparation - General 52 Elastomeric Acrylic Coatings System Application Disclaimer 53 Application — Specific Guidelines 54-89 Metal Roof Coating System 54-60 New Smooth Built-Up or Mod Bit (5 yrs or less, but aged 90 days) 60-63 Granulated Mod Bit Cap Sheet or Mineral Surface BUR Cap Sheet 64-67 Aged Smooth BUR (over 5 yrs) 68-71 EPDM Restoration System™...

Open the catalog to page 4

Now that you’ve selected one of the best brands of Elastomeric Acrylic Coatings available today, please take the time to read through this application handbook carefully before beginning. The handbook is broken into sections that provide the basic steps for applying Mule-Hide Elastomeric Acrylic Coatings over various roofing substrates, skylights, and masonry walls. general information About Mule-Hide Mule-Hide Elastomeric Acrylic Coatings are an economical alternative to extend the life of an existing roof. Advances in polymer chemistry have resulted in elastomeric coatings that provide...

Open the catalog to page 5

the standard specification for liquid-applied acrylic coatings used in roofing – ASTM D6083 (California’s Title 24 specifications mandate the application of an ASTM D6083 compliant product as the top finish coat). No responsibility, however, is implied or assumed by Mule-Hide for the design, positioning, application or functional interrelation of any building components. This is the responsibility of the architect, engineer, applicator and building owner. Mule-Hide makes acrylic coatings for applications over the following surfaces: • Metal Roofs • Industrial/Commercial • Agricultural •...

Open the catalog to page 6

1. Product Data Sheets (PDS) and Material Safety Data Sheets (MSDS) are available from the local distributor or can be downloaded from our website www.mulehide.com. 2. Remember, these are professional, commercial grade products. Always read labels and product information prior to use. 3. Always make sure any ladders being used are securely tied off and take the time to be aware of the surrounding area when on a roof. When near the edge of a roof, always work facing the edge, not with your back to it. Make sure airless sprayer hoses or cords are positioned to minimize the chance of tripping...

Open the catalog to page 7

Material Storage 1. Keep A-151 away from all ignition sources (i.e., fire, sparks, and flames). 2. Do not store any products in areas where temperatures will fall below 45°F. ACRYLIC PRODUCTS MUST BE PROTECTED FROM FREEZING AT ALL TIMES. 3. Always store materials in their original containers as labeled by the manufacturer in a secure area to prevent theft, damage, or vandalism. Follow manufacturer’s directions for proper protection of materials prior to and during installation. Any containers missing proper manufacturer’s identification are not acceptable. All materials at jobsite must have...

Open the catalog to page 8

7. Ensure that the air space below the roofing system is properly ventilated. Poorly ventilated air spaces greatly increase the probability of condensation on the bottom of a metal roof panel or roof deck. In addition, fill any gaps in the insulation below the metal roof panels. Condensation occurs when warm moist air hits a cold surface. Properly ventilating the space below the roof and ensuring that the insulation has no gaps helps to equalize the attic temperature and outdoor temperature. Be 8. careful when repairing and/or replacing fasteners on metal roofs. Make sure there are no...

Open the catalog to page 9

pre-application information getting started General Tools & Equipment Needed: Following is a list of power and/or hand tools and equipment that are typically needed to apply Mule-Hide Elastomeric Coatings: 1. Protective eyewear and gloves 2. Ladders and safety equipment (warning flags/lines, tie-offs, etc.) 3. Pressure washer & hoses 4. Stiff bristle broom and scrub brush (wire brush for metal roofs) 5. Ratchet or screw gun with sockets to remove and replace fasteners on metal roofs 6. Airless sprayer – 3000 psi minimum, 2 gallons per minute minimum material output recommended 7. Hoses &...

Open the catalog to page 10

Recommended Airless Spray Equipment Guide The following recommendations are the minimum requirements for each product. It is important to make sure all equipment and hoses are properly cleaned and stored after each use. A-125 METAL ROOF PRIMER PUMP: Airless Spray Rig with a minimum material output of .75 gal at 3000 psi. HOSES: Maximum of 300′ of high-pressure material hose. Hose ID’s are available ½″ to ¼″. Whip hose length should be one (1) ID size smaller than rest of hose length. SPRAY GUN: Airless Spray Gun. Gun must be equipped with swivel for handling ease. Gun must also be equipped...

Open the catalog to page 11All MULEHIDE catalogs and technical brochures

-

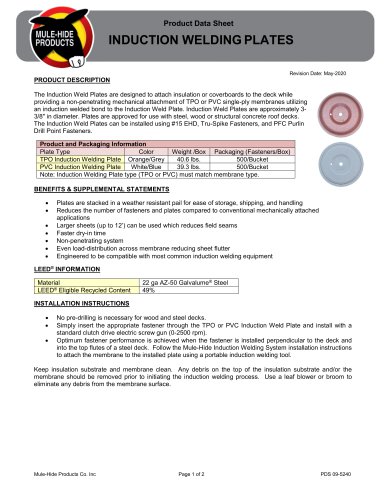

INDUCTION WELDING PLATES

2 Pages

-

Asphalt Cements

6 Pages

-

EPDM Systems Contractor

6 Pages

-

EPDM Systems

6 Pages

-

Maintenance Repair

6 Pages

-

Single Ply Roofing Accessories

44 Pages

-

PVC Architect Brochure

4 Pages

-

Living_Roof_Brochure_LR

8 Pages