Catalog excerpts

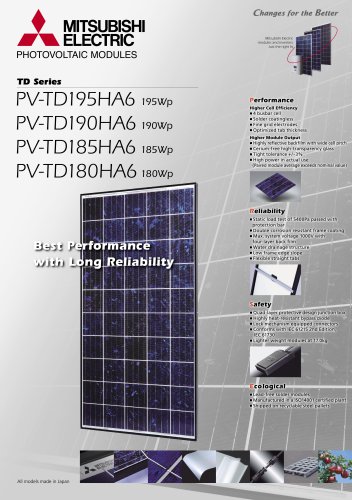

Best Performance with Long Reliability

Open the catalog to page 1

bishi Electric - A worldwide leader in power generation systems Our photovoltaic-generation technology originates from our research on Photovoltaic cells for satellites, which started back in 1974. In combination with our vast experience and accumulated know-how of power systems and semi-conductor technology, we have developed photovoltaic systems designed for superior performance and unbeatable reliability. In addition, Mitsubishi Electric is a pioneer in the photovoltaic inverter industry, commencing research and development in 1981 At Mitsubishi Electric, we integrate all of our...

Open the catalog to page 2

197H9 ' Began research and development of photovoltaic technology 1376 • Established a space-satellite business. 1981 9 Commenced joint research on industrial-use photovoltaic inverters with New Energy and / Industrial Technology Development Organization (NEDO) and on electric power utilities. 1985 Delivered high-capacity inverters (two 400kW inverters and one 200kW inverter) to Saijo City, Ehime prefecture, which continue to operate, even decades later. 1387 • Commenced research on residential-use photovoltaic inverters. Í996 m Began production and sales of residential-use inverters. 1998...

Open the catalog to page 3

Over the last 35 years Mitsubishi Electric has accumulated significant photovoltaic experience and knowledge based on our principle of research and development. Also, using our unique strengths as a leading manufacturer of electrical products, we have developed photovoltaic modules with exceptional performance and reliability. This is "Mitsubishi Electric Quality."

Open the catalog to page 4

Higher Cell Efficiency Through an industry-leading innovation of integrating four busbars into each cell, internal electrical resistance is reduced, boosting cell output by 3%. Because the distance between bus bars are shorter, the flow of electricity faces less resistance along Four busbar Arrows signify flow of electricity Solder-coatingless Cells Our manufacturing process allows us to produce cells that require no solder coating on the electrodes. The uniform light reflection off the electrode surface also contributes to high cell efficiency. Lead absorbs radiation Efficiency increased...

Open the catalog to page 6

Higher Module Output A new 60 cell array design has been Implemented In order to achieve a higher output per module, resulting In benefits such as Installation cost savings. Highly Reflective Back Film Use of a highly reflective back film In combination with a high cell pitch allows more light to be reflected onto the cells, contributing to higher efficiency. The backfilm is also designed to be a highly effective moisture barrier for long lifetime protection. Cerium-free High-transparency Glass Our modules utilize high-transparency, cerium-free glass to achieve high efficiency and...

Open the catalog to page 7

New I-frame Design /Protection Bar Building upon our already track-proven standard frame, the newly refined I-frame boasts a increase in strength by approximately twofold. The protection bar enhances the structural strength of the module, thereby enabling it to endure extreme environmental conditions. The new I-frame with protection bar allows even the larger sized module to pass the IEC 61215 static It easily passes the Impact test In which a 545g (1.18 lb) steel ball Is dropped on to the module from Double Corrosion-resistant Coating The highly durable aluminum frame is treated with two...

Open the catalog to page 8

4 Busbar Cell Stress Resistance The increased number of Busbars per cell enable a more uniform dispersion of stress on the tab. As a result, cells are more durable than before. 'Graph shows the distribution peaks of stress on the cell. New graphic-imaging technology has been introduced for aligning cells during the manufacturing process. Bus tabs are connected with more precision than ever before, thereby ensuring an overall increase in reliability and that no faulty connections are made. Cell Uniformity The cells used in our modules go through a strict selection process to ensure that they...

Open the catalog to page 9

anced Safety Multi-layer Protection The junction box is one of the most critical parts of a module in terms of safety. Safety was given the number one priority when designing our junction box. Newly redesigned junction box features multiple layers of protection against water and other risks. Improved Heatsink An original Mitsubishi Electric design, the heatsink spreads heat evenly over a large surface to allow quick dissipation from the junction box and away Interlocking Solder Connections The connection wires within the junction box are entwined together before being soldered to ensure...

Open the catalog to page 10

Protection Plate with Cable Clip Cable clips have been conveniently built Into the protection plate, thereby eliminating the need for securing tape. The cables can be quickly attached and detached, helping make installation smoother. It reduces on-site waste for an even more eco-friendly Easier Handling The new I-frame has grooves for gripping, enabling easier handling of the module. It Is especially convenient when stacking multiple modules at the Installation site, or when lifting the module from a flat surface such as the ground. Smoother Frame Edges The new I-frame has been meticulously...

Open the catalog to page 11

Lead-free Solder Mitsubishi Electric was the first Japanese company to mass produce lead-free solder modules, making our modules even friendlier to the environment. Amount of lead contained in solder for a 3kW system Conventional products Mitsubishi Electric system 'When using 24 modules of 40-cell type in a system Our factory is managed using comprehensive water conservation and recycling measures in order to minimize the impact on the environment. Factory facilities are equipped with Waste paper and other materials are Dozens of apple trees line the factory our PV systems. collected and...

Open the catalog to page 12

Nakatsugawa Works Model Naming Code Module Size (Cell Array) Cell Type Development Code Frame Type E : Global Output Power (W)

Open the catalog to page 13

bishi Electric's Photovoltaic Systems Around Small power plant Junior High School East Asia Private residence Small power plant Small power plant Private residence

Open the catalog to page 14All MITSUBISHI ELECTRIC Solar Power catalogs and technical brochures

-

UJ-GA6 Series

2 Pages

-

TD-HA6 Series

2 Pages

-

TJ-GA6 Series

2 Pages

-

MDT Series

2 Pages

-

TD Series

2 Pages

-

MJT Series

2 Pages

-

UJ Series

2 Pages

-

MLT Series

2 Pages

-

MLE Series

2 Pages

-

monocrystalline

16 Pages

Archived catalogs

-

B8292

2 Pages

-

s-serie

6 Pages

-

PV Inverter

8 Pages

-

MODULE FOTOVOLTAIC

16 Pages