Catalog excerpts

Special formwork Individual solutions for every challenge

Open the catalog to page 1

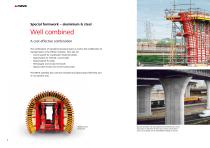

Special formwork – aluminium & steel Well combined A cost-effective combination The combination of standard and special parts as well as the modification of standard parts is the efficient solution, inter alia, for -- Corner panels for wastewater treatment plants -- Special parts for inclined, curved walls -- Special panels for slabs -- Rectangular and circular formwork -- Special steel versions for tunnel construction The MEVA assembly lock connects standard and special parts efficiently and in non-positive way. Mobile tunnel formwork. Special formwork can be produced for inclined and...

Open the catalog to page 2

The openings developed to meet the corresponding r equirements at this construction site convince through their cost-effectiveness when used a number of times. Special formwork based on the M ammut wall formwork.

Open the catalog to page 3

Special formwork made of wood For complex geometries Customised solutions Special wooden formwork is the ideal choice when between one and five pours are required without refacing. This is often the case when forming complex geometric shapes. The focus is on feasibility, cost-effectiveness, a smooth construction process and the desired concrete form. MEVA specialists develop proposals in accordance with the requirements on concrete finish, number of applications, fresh-concrete pressure loading, transport and the use on the construction site. Facing portfolio - Laminated plywood (21 mm) -...

Open the catalog to page 4

Special formwork made of wood for the production of prefabricated components. Extraordinary curved staircase in the form of a tulip created using special formwork made of wood.

Open the catalog to page 5

Special versions with alkus facings Architectural concrete in good shape Seamless surface With alkus, concrete can be poured in any desired shape. The alkus all-plastic facing is very simple and can be formed and bent with a high degree of precision. Furthermore, it can be extensively welded. This enables large, smooth concrete surfaces to be achieved without joints or imprints. Fields of application -- Highest architectural concrete requirements -- Highest requirements on uniform concrete finishes -- Large number of applications Seamless, extensively welded 20 mm facing. The welding of the...

Open the catalog to page 6

To achieve small bending radii, the alkus all-plastic facing is correspondingly machined. Milled, butt jointed and then connected with Lamello connectors without welds. Pre-bent shapes. Large-format 6 mm (GM) alkus all-plastic facing on a wooden substructure.

Open the catalog to page 7

Success can be planned A perfect overview We provide advise and then model and develop the most cost-effective solution to meet your specification – whether using the alkus all-plastic facing, wood, steel, luminium a or a combination of these. Thanks to transparent and efficient processes, together with you we realize the most c ost-effective solution for your project. Using state-of-the-art CAD systems, we create formwork plans with detailed bills of material or work together with you on your BIM project via optimised interfaces.

Open the catalog to page 8

© DHBW Stuttgart; Marko Scheerschmidt / flash.iFFect Transparent and efficient processes during planning: from the tender submission phase to the use of the finalized special formwork.

Open the catalog to page 9

More with MEVA Formwork. Simple. Smart. A lot of things that are now considered to be standard in the formwork i ndustry were developed by MEVA in Haiterbach. As a trendsetter for the entire industry, we work day in and day out with great élan to make formwork even safer, more efficient and easier to use for the end user. For us, the excellent quality of our products and technology is a matter of course. We are independent, family-run and committed to the values of a m edium-sized company in everything we do. That is why our customers may rightly expect not only technologically superior...

Open the catalog to page 10

^mple. Smart

Open the catalog to page 11

Headquarters (Germany) With 40 offices on 5 continents, we are on the spot wherever you need us. info@meva.net www.meva.net Subsidiaries/international bases LATAM lata m@ meva. net MA-Casablanca Tel. MAL-Perak Tel. N-Oslo Tel. PA-Panama City Tel. PH-Manila Tel. QA-Doha Tel. SA-Dammam Tel. SGP-Singapore Tel. UAE-Dubai Tel. USA-Springfield Tel. ▲meva MEVA Schalungs-Systeme GmbH Industriestrasse 5 Tel. +49 7456 692-01 72221 Haiterbach Fax +49 7456 692-66 Germany info@meva.net

Open the catalog to page 12All Meva catalogs and technical brochures

-

StarTec XT

16 Pages

-

FormworkPress XI/2020

24 Pages

-

MT 60 and MEP Shoring Towers

16 Pages

-

MevaDec and MevaFlex

12 Pages

-

MEVA FormSe

20 Pages

-

AluFix and EcoAs

12 Pages