Catalog excerpts

MevaDec and MevaFlex Flexible and efficient forming of slabs

Open the catalog to page 1

MevaDec The efficient and ergonomic slab formwork The new generation Lighter and more ergonomic: The new MevaDec generation convinces due to the low weight and ease of cleaning of all its components as well as its optimised handling properties - based on all the tried-and-tested MevaDec system advantages. MevaDec is not bound to a rigid grid pattern, meaning that it can be flexibly adapted to suit any building layout and any slab thickness. Minimized filler areas allow it to be set up more quickly. In the process, the predefined prop spacing ensures safety and optimised material stock on...

Open the catalog to page 2

Simply smart ÆÆ Size and weight -- Weight-optimised system for ergonomic and thus efficient work -- Largest panel 160/80 cm weighs only 16 kg/m² – almost all requirements can be covered with only one panel size ÆÆ Safety due to prop spacing defined by the system ÆÆ One system – three slab-forming methods -- Drop-head-beam-panel method -- Primary- and secondary-beam method -- Panel method Light, robust panels with ergonomic grip profiles for easy handling. Fewer compensations saves time. Even u neven slab edges can be solved with a m inimum of filler areas. Simple handling with panel...

Open the catalog to page 3

One system – three slab-forming methods Depending on the requirements, it is possible to switch freely between the methods – using the same c onnections and parts. The FTE method uses only three components: panels, primary beams and props with drop heads. MevaDec is the flexible answer for almost all slab requirements in a single system, even for slab thicknesses of well over 30 cm. The system is independent of the grid pattern in one direction, and the free selection of the beam orientation reduces the number of compensations. The HN method uses only four components: primary beams,...

Open the catalog to page 4

Safety with system All-round protection 3 Panel method (E) The panel method (E) uses only two components: panels and props with prop heads. This method is the ideal option for building layouts and filler areas involving small surface areas in conjunction with simple logistics. Thanks to the clever design of the MevaDec prop head, the panels are automatically secured to prevent them coming loose and moving unintentionally. The MevaDec support for guard-railing post is simply attached to the panel or the beam and supports the guard-railing posts. Edge protection can be attached to this, using...

Open the catalog to page 5

MevaDec A system full of ideas Material savings of up to 40% Ease of cleaning and reduced concrete adhesion (through optimised profile cross-section) High-quality cured powder-coated finish Fewer props and the optimum use of system components makes MevaDec particularly efficient. The MevaDec drop head allows for optimised material stock on the construction site and rapid construction progress. Closed profile for a high degree of stability and durability Light and ergonomic due to weight-optimised aluminium sections Ergonomic grip profile alkus all-plastic facing The alkus facing does not...

Open the catalog to page 6

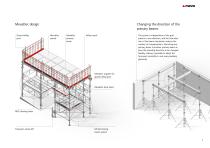

MevaDec design Guard-railing post Changing the direction of the primary beams MevaDec panels MevaDec primary beam Safety mesh The system is independent of the grid pattern in one direction, and the free selection of the beam orientation reduces the number of compensations. Mounting one primary beam in another primary beam allows the assembly direction to be changed flexibly, making it possible to adapt the formwork smoothly to suit every building geometry. MevaDec support for guard-railing post MevaDec drop head MT 60 shoring tower system 7

Open the catalog to page 7

The conventional slab formwork Economical and tried-and-tested MevaFlex: conventional slab formwork with facings, crossbeams and girder stringers on props or shoring towers. Freely selectable facing: shuttering p anel 3S, alkus all-plastic facing or other alternatives. Flexible and cost-efficient The positioning of the beams and props is not predefined and can thus be optimised in accordance with the slab thicknesses during the planning phase. This results in flexible fields of applications for varying building layouts as well as slab thicknesses. Simply smart ÆÆ High degree of efficiency...

Open the catalog to page 8

Flexible even for large surface areas MevaFlex is the ideal solution to support prefabricated slabs Flexibly adaptable to suit every building geometry

Open the catalog to page 9

More with MEVA Formwork. Simple. Smart. A lot of things that are now considered to be standard in the formwork i ndustry were developed by MEVA in Haiterbach. As a trendsetter for the entire industry, we work day in and day out with great élan to make formwork even safer, more efficient and easier to use for the end user. For us, the excellent quality of our products and technology is a matter of course. We are independent, family-run and committed to the values of a m edium-sized company in everything we do. That is why our customers may rightly expect not only technologically superior...

Open the catalog to page 10

■tuple. Smart.

Open the catalog to page 11

Headquarters (Germany) With 40 offices on 5 continents, we are on the spot wherever you need us. info@meva.net www.meva.net Subsidiaries/international bases LATAM lata m@ meva. net MA-Casablanca Tel. MAL-Perak Tel. N-Oslo Tel. PA-Panama City Tel. PH-Manila Tel. QA-Doha Tel. SGP-Singapore Tel. UAE-Dubai Tel. USA-Springfield Tel. ▲meva MEVA Schalungs-Systeme GmbH Industriestrasse 5 Tel. +49 7456 692-01 72221 Haiterbach Fax +49 7456 692-66 Germany info@meva.net

Open the catalog to page 12All Meva catalogs and technical brochures

-

StarTec XT

16 Pages

-

FormworkPress XI/2020

24 Pages

-

Special formwork

12 Pages

-

MT 60 and MEP Shoring Towers

16 Pages

-

MEVA FormSe

20 Pages

-

AluFix and EcoAs

12 Pages