Catalog excerpts

FormworkPress Professional Formwork News The XT factor Flexibility on residential contracts – page 8

Open the catalog to page 1

Imprint Site photos show situations which do not always depict the final assembly of formwork with regard to safety regulations. Imprint: Edition XI/2020. Circulation: 2600 copies. Publisher: MEVA SchalungsSysteme GmbH, Industriestr. 5, D72221 Haiterbach. Layout: MEVA. Print: C. Maurer Druck + Verlag, D-73312 Geislingen/ Steige. Reprint and re-use of any editorial ontent only by copyright permission. We c accept no liability for the content of external internet sites, nor for a violation of privacy or any other law arising from th

Open the catalog to page 2

"50 years of MEVA is a milestone that drives us on to intensify our partnerships with you, our customers." Dear Reader, Half a century ago, my father, Gerhard Dingler, had the idea of renting out cranes and other equipment for the growing construction industry. Listening closely to what building contractors and workers wanted, he soon noticed the increasing demands and expectations they placed on concrete form work. They were seeking greater safety, flexibility and cost-effectiveness for their site operations – a requirement which, indeed, has not changed since 1970. What has changed, on...

Open the catalog to page 3

Information about MEVA Joint venture in Australia Flying high with MT 60 Partnered with its distributor Novatec Formwork Systems, MEVA has succeeded in concluding another co-operation agreement. Through the Novatec MEVA Pilbara joint venture, the two companies will expand their core competencies by branching out into a new market: opencast mining in the Pilbara, a region rich in raw materials in north-western Australia. In 1898, at the age of 26, Ernst Schoemperlen established Germany's first automobile repair shop. Today, S&G Automobil AG is a Mercedes-Benz dealer with 1,400 employees. A...

Open the catalog to page 4

Specially designed formwork The use of MEVA technology on a 31-unit housing scheme in Kufstein, Austria helped to speed up site operations and achieve high concrete quality. Rieder Baugesellschaft m.b.H. & Co. KG opted to deploy up-to-the-minute MEVA systems: the new StarTec XT wall formwork along with the weightand handling-optimised MevaDec slab formwork. The name MEVA is synonymous with in-depth know-how – also in the formidable field of special designs. For the new terminal project at Frankfurt Airport, MEVA's special design experts devised a formwork solution for paired columns that...

Open the catalog to page 5

Pioneer and trendsetter Increasing customer benefit: MEVA innovations revolutionise construction industry The young Gerhard Dingler had the right instincts 50 years ago when, seeing his future in construction, he founded DINGLER Baugeräte GmbH & Co. KG. He started off by selling and renting out cranes and other equipment. Always with a listening ear for his customers and quick to spot the market demand for more modern formwork systems, he sprang into action. After setting up MEVA (an acronym of Metallverarbeitung, meaning metal processing) in 1970, he embarked on the development of safe,...

Open the catalog to page 6

by setting up the partner company BIM2. And, of course, the time-tested "hardware" – i.e. the smart, efficient formwork and climbing systems, shoring towers, props, working scaffolds, braces, etc. – also undergoes constant refinement. Constantly treading new paths With a bold, creative, pioneering spirit and a keen instinct for trends in concrete construction, MEVA has always been a trailblazer in formwork technol ogy. As early as 1971, MEVA unveiled a novelty at the leading trade show bauma that was to revo lutionise the construction industry: the first-ever modular panelised formwork...

Open the catalog to page 7

StarTec XT sails through stress test Fast, straightforward application to energise residential contracts The MEVA combination tie hole offers proven credentials: the free choice of three tying methods in a single system simplifies and speeds up formwork operations. This is already paying multiple dividends for users of the Mammut XT wall formwork system on large-scale applications. StarTec XT now guarantees the same practical benefits for residential and commercial schemes. Boasting a reputation for on-time, trouble-free, single-source project delivery, Franconian con tractor ULLI-Bau...

Open the catalog to page 8

Yet, the workers had another trial in store for the new MEVA StarTec XT: instead of being stripped af ter one to two days, as normal, the formwork was left in place for three or four days over the week end. Here, the site team wanted to test how easy it would then be to remove the taper tie for fast, sin gle-sided tying without plastic tubing. It turned out to be no problem. Ernst Muser is also impressed by the range of panel sizes – heights of 330, 270 and 135 cm, and eight widths between 270 and 30 cm – and the symmetrical tie hole and joint pattern resulting from the internal tie...

Open the catalog to page 9

Mammut XT plays to its strengths Efficiency and time-saving during construction of a new care centre in Norway Use of the single-sided tying system of the high-performance wall formwork system Mammut XT with the clever XT taper tie payd off during construction of a care centre in Norway. MEVA sales partner Maxbo Teknikk delivered the material and advised the construction company. The building with its – typically Scandinavian – clear, simple and functional architectural design is in reality a solid-wood passive house. The eye-catcher of the Omsorgssenters Biri is, however, a 18-metre-wide...

Open the catalog to page 10

thread position and back again with a flick of the wrist. It is thus possible to select flexibly between three tying methods: two-sided (conventional), sin gle-sided with XT tie rod DW 20 and plastic tube or single-sided with the practical XT taper tie without a plastic tube. Single-sided tying with the XT taper tie without a plastic tube is predestined for the construction of walls with large surface areas such as those re quired by the Omsorgssenter Biri. Jo Sandum, plant manager at Betonmast Innlandet, explains: “For this project we had to rely on the unique Mammut XT tying solution....

Open the catalog to page 11All Meva catalogs and technical brochures

-

StarTec XT

16 Pages

-

Special formwork

12 Pages

-

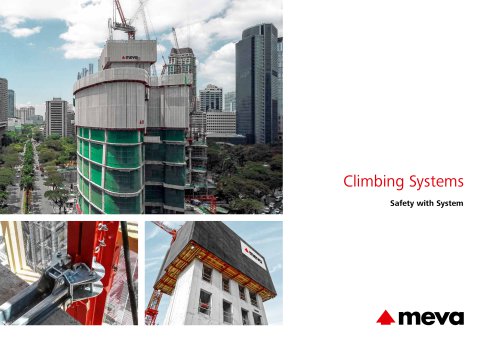

MT 60 and MEP Shoring Towers

16 Pages

-

MevaDec and MevaFlex

12 Pages

-

MEVA FormSe

20 Pages

-

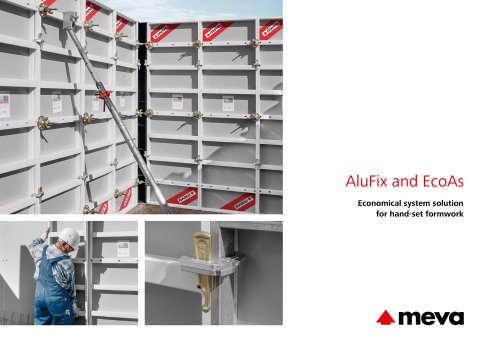

AluFix and EcoAs

12 Pages