Website:

Metalnastri

Website:

Metalnastri

Catalog excerpts

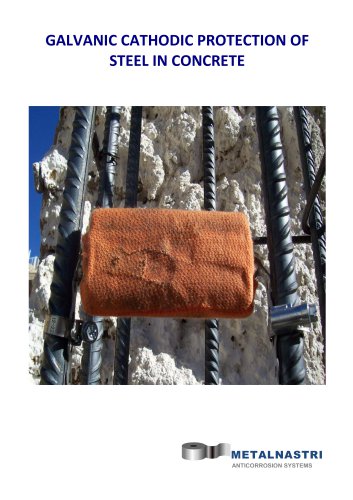

Zinc Layer Anode or ZLA is specifically developed for the CP of steel reinforcement in concrete. ZLA is a high purity zinc foil (> 99.95%) coated with an ionically conductive adhesive. It is applied directly onto the outer concrete surface. The Zinc-layer is electrically connected to the steel reinforcement. In this way the electrical-circuit is completed as the electric current flows through the adhesive layer and concrete by means of ionic conductance. As soon as the electrical connection is established, the current will flow and ZLA will begin to consume and sacrifice itself. The high conductivity of the zinc foil ensures a uniform distribution of CP current and simplifies any localised current distribution requirements. After cutting the ZLA into the appropriate length can be applied onto a cleaned concrete surface by hand application. Old concrete surfaces must be structurally sound with any unsound areas being repaired prior to the installation of ZLA. Laitance and other surface contaminants also need to be removed. Holes, cracks and other surface defects need to be cleaned and filled with an approved method using a mineral cement-based mortar. The patch surface should be smooth. For a small section the adhesive protective liner should be removed first. For larger sections the liner is removed slowly and the ZLA pushed onto the surface at the same time. It is recommended to check the application by moving and pushing a rubber hammer over the total length of the applied ZLA. ZLA is provided in rolls (250 mm wide by 25 meters long). After application ZLA should be finished with an approved cementitious based coating of the specified texture and colour, ensuring edges and seams are properly over coated to avoid moisture ingress. System monitoring can be performed according to the standard ISO 12696. Effectiveness: ZLA eliminates corrosion by operating as a galvanic anode Versatility: ZLA can be applied to the top, sides, or bottom surfaces of concrete structures of various shapes and any sizes. Economics: ZLA requires minimal maintenance over its long life. If desired, performance can be monitored easily by on-site personnel. With a 250 micron zinc layer the calculated life expectancy will be 21 years. Upon request the anodes can be modified to achieve a life span of 40 years plus. METALNASTRI ANTICORROSION SYSTEMS Metalnastri S.r.l. - Via Padova 3 20063 Cernusco sul Naviglio (Milan) - ITALY 5? +39 02 92 59 20 60 - S +39 02 92 47 16 16 www.metalnastri.it - info@metalnastri.it

Open the catalog to page 1All Metalnastri catalogs and technical brochures

-

GSC

2 Pages