Catalog excerpts

Introduction 3 - About MEISER 4 - The MEISER grating 6 - Te c h n i c a l t e r m s 10 - Material 14 - Galvanising 15 - Surface finishing 16 18 22 24 25 26 26 28 29 Shelf grating - Fitting on top versions - Inlaid versions - MEISER Modul - U-Profile shelf grating - Product versions - Versions with heat sink sheet metal - Checklist Welded press-locked gratings - Applications - Welded press-locked gratings with perforated sheet metal strips - Offshore press welded grating - Welded press-locked gratings with smooth round bars Special grating - Applications - Finned grating - Barefoot grating -...

Open the catalog to page 3

ABOUT MEISER MEISER, founded in 1956, is a medium-sized, ownermanaged family business with its company headquarters in Schmelz-Limbach in the Saarland. In the field of grating MEISER has a leading position worldwide. The product range is supplemented by other business segments. This includes the field of steel processing with its own slitting plants and cold rolling centres. Furthermore, MEISER operates traditional hot dip galvanising plants and a strip galvanising plant. The diversification is rounded off by the production of sheet metal profile grating, staircase systems, special...

Open the catalog to page 5

MEISER Press Locked Grating Grating is a structural element that has a high loadbearing capacity with a low dead weight and a high level of transparency. The positive-fitting connection of the bearing bars and cross bars with the surround make the grating not only a very stable, but also visually attractive product. The applications are very diverse, as grating is used everywhere in industry and architecture. As an extremely robust, safe yet light platform flooring, the grating is indispensable in all areas of heavy indus- try. Grating is installed in refineries, power stations, steel...

Open the catalog to page 6

wide. The diversity of possible applications also requires an unusually large variety of products. Together with our customers we select the right grating from our range. Grating is almost always relevant to safety, and we are well aware of this responsibility. When one is standing high up on a „breezy“ platform made of MEISER grating, one understands the importance of quality and reliability. We set the highest standards for our products – from the planning stage to delivery. MEISER grating is 100 % made by MEISER. More than 80 % of all grating are made to measure at our two factories in...

Open the catalog to page 7

TOP: VIEWING PLATFORM, GÖTTELBORN BOTTOM, LEFT TO RIGHT: UNIVERSITY MANNHEIM; NEW APOSTOLIC CHURCH FRANKENTHAL; MUSEUM BURG HEINFELS, AUSTRIA

Open the catalog to page 9

TECHNICAL TERMS Bearing bars Cross bars Bearing bars are load-bearing, vertical flat bars which run parallel to one another from one support to the next. The cross bars run at right angles to the bearing bars, connecting them together through compression and/or welding at the crossover points. Edge banding Mesh width All grating is banded as a rule by flat bars, T-shaped sections or U-shaped sections. (a) the clear distance between the bearing bars or the cross bars. Mesh spacing (b) distance from centre to centre of bearing bars or the cross bars. Mesh size The mesh size is largely...

Open the catalog to page 10

Support beam centres Grating landing Is the centre-to-centre distance of the support in the direction of the bearing bar. The term „grating landing“ is used to describe the length of the bearing bar ends which lie on the support structure. It should correspond to the height of the bearing bars, but also be at minimum of 30 mm. Clear Span Is the clear distance between two supports. Installation / Erection clearance The installation clearance is used during assembly to compensate for tolerances between the steel structure and grating. If the total length of the cutout is less than 0.5 mm, we...

Open the catalog to page 11

TECHNICAL TERMS Deep Banding Kick Plate Reinforced and raised edge surround downwards, e.g. in order to achieve a certain installation height. A raised surround plate, also known as a toe plate, is welded on, increases safety when walked on and protects against sliding at the grating edge. This is necessary if the clearance between the grating and the adjacent component is more than 30 mm.

Open the catalog to page 12

LEUNA HARZE Anti-skid-properties (Serrations) Special notching of the bearing bars and the panel banding bars local to the support structure (notches should be not more than half the height of the bearing bars). Notching of bearing and cross bars to increase slip resis-tance.

Open the catalog to page 13

MEISER has its own slitting plants, wire drawing devices and cold rolling centres. We are therefore able to design a grating exactly in accordance with the requirements and wishes of our customers. Here, oversizing makes little sense, while undersizing must be avoided under all circumstances. The ideal combination of material thickness and height, associated with the matching steel quality, ensures the greatest possible economic benefits. That is our aspiration - not more and not less. We would like to explain the best-known versions to you below: Steel grades S 235 JR (DIN EN 10025-2)...

Open the catalog to page 14

Galvanised products in general Our galvanising plants in Limbach and Oelsnitz are among the most modern hot-dip galvanising plants in Europe. The systems’ modern design allows MEISER to operate completely without pollutants. Every product to be galvanised is first picked up autonomously by the traverse and guided through the plant. During the previous production step, oils and fats are used on the gratings to reduce machine wear. Before the gratings can be galvanised, however, their surface must be free of any contamination. Likewise, they must also be freed from all rust particles and...

Open the catalog to page 15

SURFACE REFINEMENT Surface refinement MEISER grating is characterised by durability and high quality. This crucially depends on the correct surface treatment. In this respect we offer our customers numerous possibilities - be this with the focus on functionality or aesthetics. For the selection of the surface treatment there are various factors which are decisive: the personal preferences of our customer, their budget and questions of corrosion protection. Hot dip galvanising MEISER grating manufactured from mild steel is usually hot dip galvanised. In our new plants in Limbach and...

Open the catalog to page 16All MEISER catalogs and technical brochures

-

Profile Planking

108 Pages

-

Sheet Metal Forming

8 Pages

-

Profile Planking and Stairtreads

82 Pages

-

Special grating

16 Pages

-

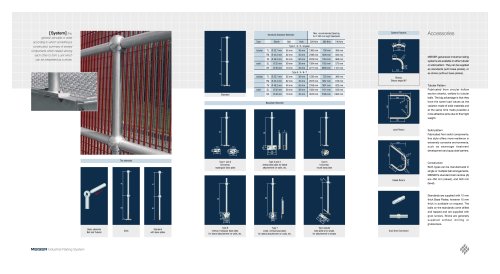

Industrial railing system

2 Pages

-

Staircases

62 Pages