Catalog excerpts

Professional warewashing technology WS 125 Cart washer Machine decontamination for carts

Open the catalog to page 1

WS 125 cart washer – Sophisticated, powerful and hygienic cleaning solutions for carts

Open the catalog to page 2

Hygienic cleanliness is a number one priority in hospitals, clinics, residential homes and other areas such as laboratories. Items like dishes, food, laundry and waste are transported back and forth using carts – and making sure these carts are hygienically cleaned is essential. The MEIKO WS 125 cart washer has been specially developed to guarantee this high standard of hygiene. The WS 125 features a highly effective power wash and rinsing system to hygienically and efficiently clean your carts. The machine structure is 100 % stainless steel and it is available in through loader and front...

Open the catalog to page 3

WS 125 Designed by professionals for professionals – special features Automatic cart tilting Allows the water to drain efficiently from the surfaces and the interior. This ensures both excellent cleaning and great drying results. The two-part wash and rinse systems are adapted to the cart on the left, right and top. The systems move in a cycle and reach the entire cart surface several times per wash cycle.

Open the catalog to page 4

The large wash chamber (fig. shows version with 2 drying systems per side) provides plenty of room for all industry standard carts. The washer is installed level with the floor so it is easy to load and unload carts and, depending on the size of your carts, more than one can be washed at once. High volume nozzles on the drying system combined with large volumes of air and the right heating performance to ensure superb drying results. Wash water filter system Several filter boxes are in use during the wash process to remove all of the residues which are washed off. The tilted floor means...

Open the catalog to page 5

Our PLC system controls a chemical-thermal wash process with a water agitation system. All of this comes together to ensure excellent wash and disinfection results. The design and the moving technology complies with the profile required by the AK-BWA (workgroup on bed frame and cart washers). Schematic representation of programme run and temperature curve Full decontamination programme Progress through time (t) See: AK-BWA, machine decontamination In addition to the food distribution carts already shown, the MEIKO WS 125 cart washer is also ideal for thermoport carts, shelf trolleys,...

Open the catalog to page 6

WS 125 – Plan for how you work and get the most out of your machine Warewashing organisation in a hospital kitchen with 1,200 diners. Washing using dual chamber machine (2 x WS 125-M) in a through loader system. 4 waste chutes for dishes and gastronorm containers have been integrated onto the flight type dishwashing machine to maximise the efficiency of this dishwashing area. This way, the MEIKOWasteStar system's vacuum technology can be used to automatically and efficiently dispose of food waste, feeding it into the storage tank. CLEAN Hospital warewashing system and equipment for 800...

Open the catalog to page 7

fllEIKO The clean solution * Depending on size of cart ** When connected to hot or cold water supply with exhaust air heat recovery The machines are installed ready for connection and operation. As standard, they work with three-phase current, 3 NPE 400 V, 50 Hz (other heating options available on request). Circuitry complies with the requirements of the Association of German Electrical Engineers (VDE). The machines can be connected directly to the fresh water connection without the use of intermediate safety valves. Soft hot or cold water, DN 25; 0-3 °dH. Flow pressure 2.5 bar; maximum...

Open the catalog to page 8All MEIKO catalogs and technical brochures

-

MEIKO rack range

12 Pages

-

M-iQ crate washer

2 Pages

-

Professional warewashing

36 Pages

-

TOPIC optional extras

12 Pages

-

Reusable dishware

8 Pages

-

BTA 160 / BTA 240

6 Pages

-

UPster

12 Pages

-

Catalogue M-iQ Green Eye

20 Pages

-

Catalogue TopLine Product range

12 Pages

-

M-iQ

36 Pages

-

FV 60.2

6 Pages

-

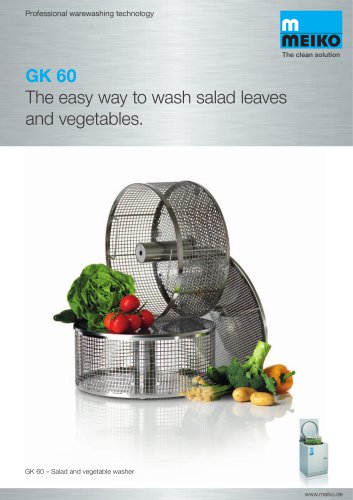

GK 60

8 Pages