Catalog excerpts

Efficient automation of the wash-up area BTA 160 / BTA 240 Automatic tray washing machine

Open the catalog to page 1

BTA 160 / BTA 240 The efficient automation modules for your scullery

Open the catalog to page 2

The automatic washing of trays delivers considerable benefits. The development by MEIKO of the BTA 160 and BTA 240 tray washer has provided the answer for the simple, quick, efficient, and cost effective washing of trays for a wide and varied clientele base. Up to 24 trays per minute can be processed, depending on the actual tray size. The compact construction and the exceptional price/performance ratio enables individual design concepts to be introduced in virtually all wash-up areas. Trays no longer need to be pickedup and placed on the washing machine belt manually as they are...

Open the catalog to page 4

fllEIKO The clean solution The powerful washing system located both above and below the tray ensures a maximum cleaning result. This is followed by an intensive hot fresh water final rinse of each tray. To ensure a first class drying result the tray transport cords are separated between the final rinse section and the drying zone. Trays are transported therefore on „dry“ round belt cords when in the drying zone. An integral exhaust fan ensures that excess vapours are continually removed from the machine, ensuring comfortable working conditions within the wash-up area. An optional heat...

Open the catalog to page 5

BTA 160 / BTA 240 Dimensions and technical data The machine is constructed throughout in high grade stain-less steel and is double wall insulated for first class sound and heat insulation. Potential-free contacts are provided within the electrical control panel to enable the exhaust fan of the machine to be linked to the building extract system, for the connections of the chemical dosing apparatus, and for the tray transport conveyor system. Optional: Steam heating of wash tank and booster heater. kW values of heating capacity can vary w 5 % 320.031.01.12.18/EN/digital We reserve the...

Open the catalog to page 6All MEIKO catalogs and technical brochures

-

MEIKO rack range

12 Pages

-

M-iQ crate washer

2 Pages

-

Professional warewashing

36 Pages

-

TOPIC optional extras

12 Pages

-

WS 125

8 Pages

-

Reusable dishware

8 Pages

-

UPster

12 Pages

-

Catalogue M-iQ Green Eye

20 Pages

-

Catalogue TopLine Product range

12 Pages

-

M-iQ

36 Pages

-

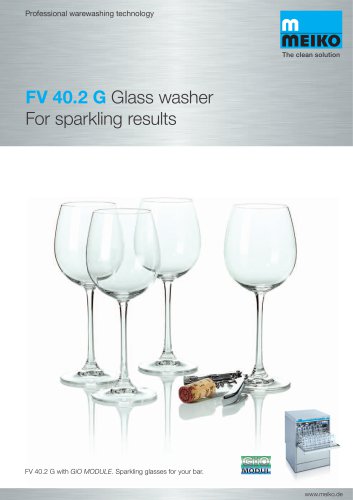

FV 60.2

6 Pages

-

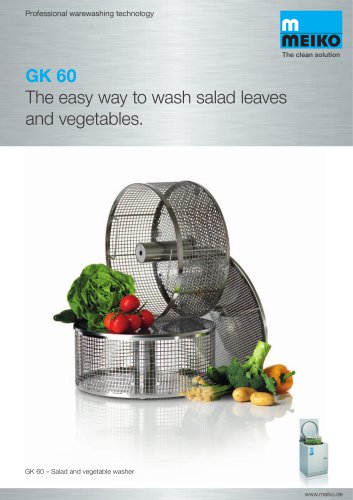

GK 60

8 Pages