Catalog excerpts

HDPE drainage January 2011

Open the catalog to page 1

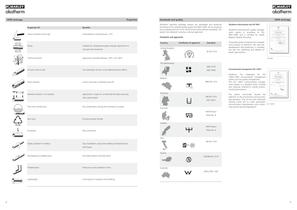

System overview System overview The Akatherm HDPE drainage system The Akatherm HDPE drainage system has been used for more than 40 years has been used for more than 40 years in areas application where the drainage areas ofof applicationwhere the drainage system has meet high standards of system has to to meet high standards of durability and reliability. These durability and reliability. These standards are met by combining the standards are met by combining the excellent material properties of HDPE excellent material properties of HDPE with homogeneous welded joints. with homogeneous...

Open the catalog to page 2

HDPE drainage HDPE Drainage Properties Properties Properties PE Benefits Impact-resistant and tough Unbreakable at temperatures > 5ºC HDPEHDPE drainage Drainage Standards and quality Standards and quality Akatherm specialist drainage systems are developed and produced according to the certified quality system ISO 9001:2000. All our products are complying with EN 1519, ISO 8770 and other relevant standards. The system has obtained numerous national approvals. Standards and approvals Country Elastic Suitable for underground pipes through adjustment to local ground movement Certificate of...

Open the catalog to page 4

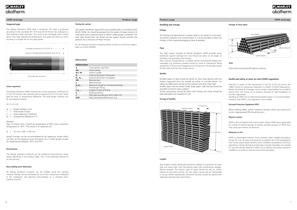

HDPE drainage HDPE Drainage Product range Product range HDPEHDPE drainage Drainage Product range Product range Tempered pipe Testing the system Handling and storage The Akatherm HDPE pipe is tempered. tempered. This pipe according to Marley Akatherm HDPE pipe is This pipe is produced is produced according to the 1519 and ISO 1519 but has undergonehas undergone a the standards EN standards EN 8770 and ISO 8770 but a heat treatment heat treatment The result is less The result is less cooled down from high after extrusion. after extrusion. shrinkage when shrinkage when cooled down from...

Open the catalog to page 5

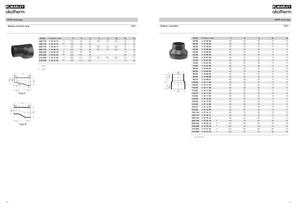

HDPE drainage Reducer eccentric long Product code HDPE drainage Reducer concentric Product code butt-weld only

Open the catalog to page 7

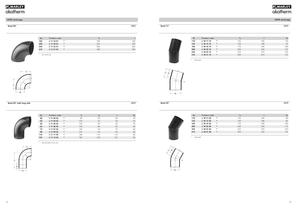

HDPE drainage Product code butt-weld only Bend 90° with long side Product code HDPE drainage Product code Product code

Open the catalog to page 8

HDPE drainage Product code - continued over - HDPE drainage Product code Product code Clean out branches 45° can be applied in horizontal and vertical pipes.

Open the catalog to page 11

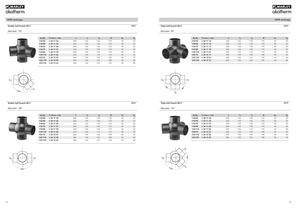

HDPE drainage Double ball branch 88.5° Double ball branch 88.5° Product code HDPE drainage Triple ball branch 88.5° Product code Triple ball branch 88.5° Product code

Open the catalog to page 13

HDPE drainage Fourfold ball branch 88.5° Product code Aerator Akavent Product code butt-weld only The Akavent aerator interrupts the fall of the wastewater on every floor resulting in a reduction of the speed. The vent pipe is obsolete and the unique design increases the capacity of the riser. The Akavent aerator will be delivered with closed caps. After removing the caps, the required branches can be butt-welded to the aerator. When the connection will be made with snap socket Art. Nr. 40xx10a tight-fit plug-in connection is created. Then a transition to other material is also possible....

Open the catalog to page 14

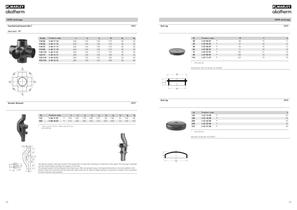

Properties HDPE drainage HDPE drainage Protection plug HDPE Tools Tools HDPE drainage Control box Akafusion CB315 Akafusion d1 90 110 Art. Nr. Product code S 43 09 19 S 43 11 19 D D1 D2 L l1 109 130 90 105 103 119 98 98 27,0 23,5 d1 40-315 Art. Nr. Product code 41 98 00 S Dim. V~ Hz kg A max W max 270x245x175 230 50/60 4,3 10 2300 The Akafusion CB315 control box is suitable for welding electrofusion couplers from d1 40-160 mm (with yellow cable) and electrofusion couplers from d1 200-315 mm (with blue cable). Yellow and blue output leads are standard supplied with control box Art. Nr....

Open the catalog to page 20

d1 = 40-50-56-63-75-90-110-125-160. Suitable for welding Y-branches 45°. d1 = 40-50-56-63-75-90-110-125-160. Suitable for welding Y-branches 45°. HDPE drainage Tools Butt-welding machine 250C Tools Tools Butt-welding machine 250C Welding plate HDPE drainage d1 d1 75-250 Product code Art. Nr. S 49 30 00 L B H 835 565 760 75-250 kg Art. Nr. 49 30 00 L 835 Art. Nr. Product code 160 B H kg 565 760 160 S 49 00 10 d1 = 75-90-110-125-160-200-250. Suitable for welding Y-branches 45°. For welding pipe and fittings up to 110 mm size. The welding plate is delivered including case and holder. d1 =...

Open the catalog to page 21

Jointing methods Electrofusion, the most simple and rapid jointing technique, is mainly used on construction sites for a highly efficient method of assembly for pipes, fittings and prefabricated sections. Electrofusion couplers The PE range includes couplers in the diameters 40 to 315 mm. The couplers are extremely suitable for applications in waste water and rainwater drainage, with the following features: 1. Injection molded with excellent dimensional accuracy and stability. 2. One welding indicator on each welding surface for checking both welding connections. 3. Centre stops easy to...

Open the catalog to page 22

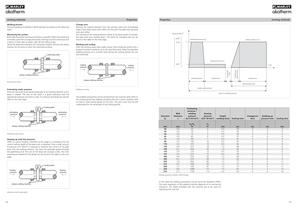

Jointing methods Welding process The butt-welding of Akatherm HDPE operates according to the following Both sides should be machined until they run parallel. When the machining is finished, open the carriages (the plastic shavings must be continuous and uniform in both sides to weld). Take off the milling cutter. Verify the alignment between the machined surfaces. Remove the plastic shaving. Do not dirty or touch the machined surfaces. machining cutter clamps welding machine Preheating under pressure Press the two ends to be jointed gradually to the heating element until a bead is created....

Open the catalog to page 23

Jointing methods Evaluating the butt-weld joint The butt-weld can be evaluated using destructive and non destructive evaluation methods. For these evaluations special equipment has to be used. Butt-welds can easily be judged by a visual inspection making this the recommended method for a first evaluation. The shape of the welding bead is an indication for the proper operation of the welding process. Both welding beads should have the same shape and size. The width of the welding bead should approximately be 0.5 x the height. Differences between the beads can be caused by the difference in...

Open the catalog to page 24

Jointing methods Flange joint The flanged joint is a detachable joint not that common in soil and waste systems. It is the ideal jointing method to connect the system onto flanged equipment and to install valves. The joint can be made by the following steps: - Mount backing ring over pipe or fitting - Weld stub flange to fitting or pipe - Apply seal - Mount bolts, nuts and washers and tighten nuts with the bolt torque mentioned in the next table. Bolt torque for non-pressure applications Contraction sleeve A simple transition to other materials than HDPE can be made using the contraction...

Open the catalog to page 25All Marley Plumbing & Drainage catalogs and technical brochures

-

New Product Guide MARCH 2021

3 Pages

-

Roofing Accessoiries

33 Pages

-

Multikwik®

50 Pages

-

Underground

27 Pages

-

PRODUCT PORTFOLIO

11 Pages

-

Rainwater

23 Pages

-

ABOVE AND BELOW GROUND

41 Pages

-

soil waste

27 Pages

-

ABOVE GROUND

35 Pages

-

Anti-flood valve datasheet

2 Pages

-

Sanitary Systems technical guide

17 Pages

-

Sanitary Systems Brochure

13 Pages

-

Marley Range

11 Pages

Archived catalogs

-

underground drainage system

23 Pages

-

PRODUCT PORTFOLIO_2017

11 Pages

-

RAINWATER_2017

19 Pages

-

Marley Sanitary

13 Pages

-

Marley Rainwater

28 Pages